Read Part 2 First : ECU Map Training (Reading & Writing ) – Part 2

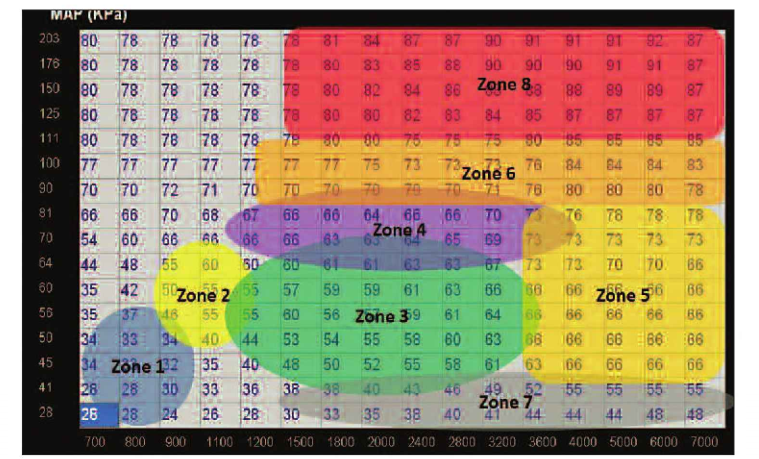

Zone 6

A naturally aspirated engine will travel through this zone at WOT. Manifold pressure may be slightly lower than atmospheric pressure if there is some restriction in the intake system plumbing and filter. Remember that at higher altitudes, this zone may include MAP values as low as 70 kPa since that’s all that is available from the atmosphere at WOT. The only way the engine gets here is by application of full throttle, so the objective is maximum output. Achieving this is aided by some amount of fuel enrichment, usually to so the most effective use of intake oxygen is made. The additional fueling also helps to control exhaust component temperatures as seen in Zone S. Timing is set as close to MBT as possible without getting into knock. Boosted engines will also pass through Zone 6 at part throttle on their way to full load. Within this zone, the engine doesn’t know that it’s supercharged and can be treated just the same as if it were a naturally aspirated version of itself for both spark and air/fuel ratio. If the engine is a low compression variant, this typically means that volumetric efficiency and torque output within Zone 6 are lower than the higher compression naturally aspirated equivalent.

Zone 7

Whenever the throttle is abruptly lifted, manifold pressure drops to its minimum and Zone 7 is entered. Get- ting into this zone requires that the throttle be almost completely closed. By getting here, the driver is basically requesting zero or negative torque output. He wishes to slow down as quickly as possible. If the torque request is zero (or less), it makes engine control very simple. In order to produce zero torque, zero fuel is required. Many OEM systems have strategies to recognize this set of conditions and employ what is known as deceleration fuel cutoff (DFCO) to assist in engine braking. Removing 100% of the fuel and engine torque precaution means that engine braking will be much more pronounced. This can be achieved by simply modeling the volumetric efficiency as zero within Zone 7. Zero VE means zero airmass, and at any ratio still equals a command of zero fuel mass delivered. If deceleration fuel cutoff is not desired, the engine can set to run at lambda=1.CX) just like Zone 3 above it. Errors in the calculated volumetric efficiency are harder to notice here, since the engine typically sweeps through this zone pretty quickly. Even though loads are exception- ally low in this zone, spark advance does not necessarily need to be that high. The same values as shown in Zone 3 above are a good starting point. Adding too much spark advance in Zone 7 may result in a “popping” noise in the exhaust.

Boosted engines have the ability to generate higher manifold pressures than their naturally aspirated equivalents. Whenever this happens, they leave Zone 6 and travel vertically into Zone 8. The cylinder loads become significantly higher in this zone as more air and fuel molecules are force fed into the same physical chamber volume. With this increase in pres- sure comes heat, which is further compounded by the additional heat generated by actually burning larger amounts of air and fuel in the same chamber. This added heat dumps more energy into the engine’s cooling system as piston, valve, and cylinder head temperatures are all increased with the added heat release of a larger combustion event on each cycle. The increase in heat means that flame speeds will generally increase and the knock threshold is greatly reduced. In order to maintain safe operation, extra fuel is added in Zone 8 for a mild cooling effect as well as increased knock margin. At moderate boost levels, a target ratio of lambdaz0.80 may be sufficient, but some non-intercooled applications may benefit from running ratios closer to lambda=0.75 for added safety. Any time a close-coupled catalyst is used in a high output engine, brick temperature limits may require additional fuel for cooling of the exhaust gases. In some OEM applications, this can trump the typical ratios desired for clean combustion as ratios as rich as lambda=O.65 have been used to keep from melting what was once an expensive catalyst brick into what closely resembles moon rocks. Ignition timing strategy for Zone 8 closely follows the goals of Zone 6. The object is to run as close to MBT timing as possible without getting knock. The added cylinder load and temperatures of Zone 8 often mean there is a significant gap between the knock limit MBT at most points. As such, the delivered timing is almost always a reflection of how close to the knock limit the engine calibrator is willing to run, or how much confidence he has in the knock sensor logic. This is a condition where higher octane fuels with their higher knock resistance can allow the engine calibrator to unlock more power from the same engine hardware if all else is equal with operating conditions. With most blends of pump gasoline, power is limited by how close to the edge the calibrator is willing to run the engine on an extended basis. Most experienced tuners will opt to maintain a significant safety margin for knock in Zone 8 instead of trying to eke out that last bit of horsepower.