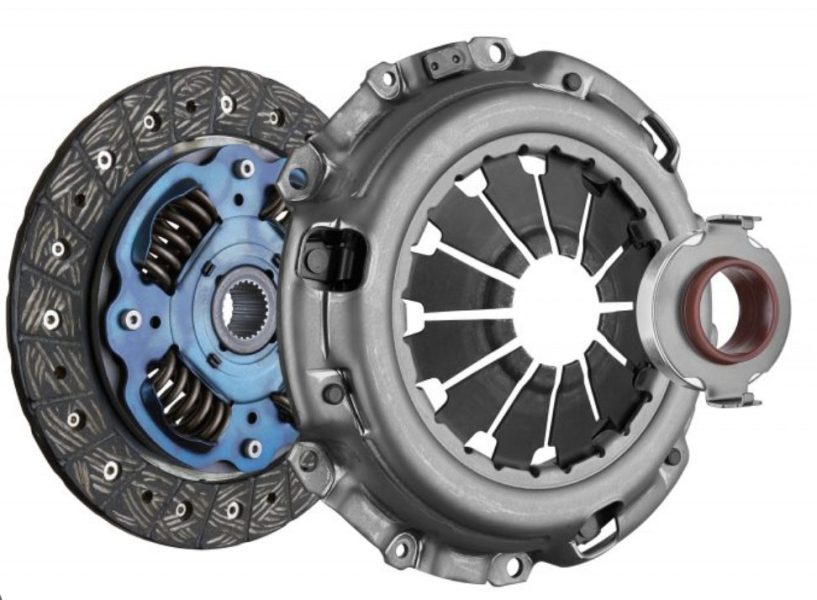

Clutch plates are an essential component of a manual transmission system in vehicles. They help transmit power from the engine to the wheels by engaging and disengaging the transmission. There are several types of clutch plates, but in this blog, we’ll be focusing on the driven plate and pressure plate.

Driven Plate:

The driven plate is a type of clutch plate that is located between the flywheel and the pressure plate. It is also known as the clutch disc. The driven plate consists of a metal plate with friction material attached to both sides. The friction material is made of a composite material that can withstand high temperatures and pressures.

When the clutch pedal is depressed, the pressure plate releases the driven plate from the flywheel. This disengages the transmission from the engine, allowing the driver to shift gears. When the clutch pedal is released, the pressure plate engages the driven plate with the flywheel, transmitting power from the engine to the wheels.

Pressure Plate:

The pressure plate is the other type of clutch plate that is mounted on the flywheel. It is responsible for applying pressure to the driven plate, which in turn transmits power to the transmission. The pressure plate consists of a metal plate with a diaphragm spring or coil springs attached to it.

When the clutch pedal is released, the diaphragm spring or coil springs apply pressure to the driven plate, which engages with the flywheel. This allows power from the engine to be transmitted to the wheels. When the clutch pedal is depressed, the diaphragm spring or coil springs release the pressure on the driven plate, allowing it to disengage from the flywheel.

In summary, the driven plate and pressure plate are two essential components of a manual transmission system. The driven plate is responsible for transmitting power from the engine to the transmission, while the pressure plate applies pressure to the driven plate to engage with the flywheel. Proper maintenance and replacement of these components are critical for the smooth operation of a vehicle’s manual transmission.

Driven Plate:

The driven plate or clutch disc is made up of a metal plate with friction material attached to both sides. The friction material is typically made of a composite material consisting of cellulose fiber, resins, and other materials that can withstand high temperatures and pressures. The driven plate is mounted on the transmission input shaft and is sandwiched between the flywheel and the pressure plate.

When the clutch pedal is depressed, the pressure plate releases the pressure on the driven plate, allowing it to disengage from the flywheel. This disconnects the engine from the transmission and allows the driver to shift gears without damaging the transmission or engine. When the clutch pedal is released, the pressure plate applies pressure to the driven plate, forcing it against the flywheel. This engages the transmission with the engine and allows power to be transmitted from the engine to the wheels.

Pressure Plate:

The pressure plate is mounted on the flywheel and is responsible for applying pressure to the driven plate. The pressure plate consists of a metal plate with a diaphragm spring or coil springs attached to it. The springs are designed to apply pressure to the driven plate when the clutch pedal is released, forcing it against the flywheel.

When the clutch pedal is depressed, a release bearing or throw-out bearing pushes against the diaphragm spring or coil springs, releasing the pressure on the driven plate. This allows the driven plate to disengage from the flywheel, disconnecting the engine from the transmission. When the clutch pedal is released, the diaphragm spring or coil springs apply pressure to the driven plate, forcing it against the flywheel and engaging the transmission with the engine.

Maintenance:

The driven plate and pressure plate are subject to wear and tear over time and may need to be replaced periodically. Signs that these components need to be replaced include slipping or grabbing of the clutch, difficulty shifting gears, or a burning smell coming from the transmission. Regular maintenance of the clutch system, including regular inspection and adjustment of the clutch pedal, can help extend the life of these components and ensure smooth operation of the manual transmission.

In conclusion, the driven plate and pressure plate are essential components of a manual transmission system. Proper maintenance and replacement of these components are critical for the safe and smooth operation of the vehicle. If you notice any signs of wear or damage, it’s important to have the clutch system inspected by a qualified mechanic.