Lambda sensors, also known as oxygen sensors, are essential components in the modern automobile industry. They play a vital role in the fuel injection system by monitoring the amount of oxygen in the exhaust gases and adjusting the fuel-to-air ratio accordingly. One type of lambda sensor is the zirconia type, which utilizes a zirconia ceramic material as its sensing element. In this blog, we will discuss the construction of a zirconia type lambda sensor, its working principle, and its importance in the automotive industry.

Construction of a Zirconia Type Lambda Sensor:

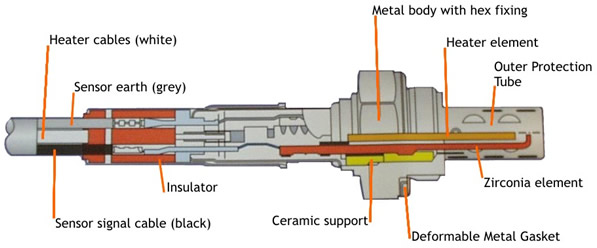

A zirconia type lambda sensor consists of a ceramic sensing element, a heater, and a metal casing. The sensing element is made up of a thin layer of zirconia ceramic material, which is coated with a porous layer of platinum on both sides. The porous platinum layer acts as a catalyst, and when heated, it reacts with the oxygen in the exhaust gases to produce a voltage.

The heater is a small electrically powered device that heats up the sensing element to its operating temperature of around 300-400°C. The metal casing protects the sensing element and heater from damage and also provides a means for mounting the sensor onto the exhaust system.

Working Principle of a Zirconia Type Lambda Sensor:

The zirconia type lambda sensor works on the principle of the Nernst equation, which states that the voltage produced by a cell is proportional to the logarithm of the ratio of the concentrations of the reactants and products involved in the reaction. In the case of a zirconia type lambda sensor, the reactants are the oxygen in the exhaust gases and the platinum-coated zirconia sensing element, while the products are water and carbon dioxide.

When the engine is running, the exhaust gases pass over the platinum-coated zirconia sensing element, which is heated up to its operating temperature by the heater. The platinum acts as a catalyst and reacts with the oxygen in the exhaust gases to produce a voltage. The voltage produced by the sensor is directly proportional to the amount of oxygen present in the exhaust gases. This voltage signal is sent to the engine control unit (ECU), which uses it to adjust the fuel-to-air ratio of the engine.

Importance of Zirconia Type Lambda Sensors:

Zirconia type lambda sensors are critical components in modern automobile engines. They play a vital role in ensuring that the engine runs efficiently and emits lower levels of harmful pollutants into the environment. Without a functioning lambda sensor, the engine control unit would not be able to adjust the fuel-to-air ratio, resulting in poor performance, increased fuel consumption, and higher emissions.

In addition to their role in the fuel injection system, zirconia type lambda sensors are also used in other automotive applications, such as in catalytic converters, where they help to reduce the amount of harmful pollutants released into the environment.

Conclusion:

The zirconia type lambda sensor is a crucial component in the modern automobile industry. It utilizes a zirconia ceramic material as its sensing element, which reacts with the oxygen in the exhaust gases to produce a voltage signal. This signal is used by the engine control unit to adjust the fuel-to-air ratio, ensuring that the engine runs efficiently and emits lower levels of harmful pollutants into the environment. Without a functioning lambda sensor, the engine would not be able to operate correctly, resulting in poor performance and higher emissions.

Zirconia ceramic material is an excellent choice for the sensing element in lambda sensors because it has the unique property of being an oxygen ion conductor. This means that at high temperatures, oxygen ions can move through the crystal structure of the zirconia, allowing it to measure the concentration of oxygen in the exhaust gases.

To increase the sensitivity and accuracy of the sensor, the platinum layer on the zirconia sensing element is made very thin and porous, which provides a large surface area for the oxygen to react with the platinum. This reaction generates a voltage signal that is directly proportional to the concentration of oxygen in the exhaust gases. The voltage signal is typically in the range of 0.1 to 0.9 volts, with a signal of 0.45 volts indicating a stoichiometric fuel-to-air ratio (i.e., the ideal ratio of fuel to air for complete combustion).

One of the main advantages of the zirconia type lambda sensor is its ability to operate at high temperatures. This allows it to be used in harsh automotive environments, where temperatures can exceed 1000°C. The heater in the sensor helps to bring the sensing element up to its operating temperature quickly, allowing the sensor to provide accurate readings in a short amount of time.

In addition to their use in automotive applications, zirconia type lambda sensors are also used in industrial settings to monitor oxygen levels in industrial processes, such as combustion processes, where accurate control of the fuel-to-air ratio is critical for efficiency and emissions control.

Overall, zirconia type lambda sensors are essential components in modern automotive and industrial applications. They play a crucial role in ensuring that engines and industrial processes run efficiently and emit lower levels of harmful pollutants into the environment.

Advantages:

- High accuracy: Zirconia type lambda sensors are highly accurate in measuring the concentration of oxygen in the exhaust gases. This allows the engine control unit to adjust the fuel-to-air ratio to ensure optimal performance and lower emissions.

- Fast response time: The heater in the sensor helps to bring the sensing element up to its operating temperature quickly, allowing the sensor to provide accurate readings in a short amount of time.

- Durable: Zirconia ceramic material is highly resistant to corrosion and can withstand high temperatures, making it a durable material for lambda sensors.

- Wide operating range: Zirconia type lambda sensors can operate in a wide range of temperatures, making them suitable for harsh automotive and industrial environments.

- Low maintenance: Zirconia type lambda sensors require little maintenance and have a long lifespan, making them a cost-effective option for automotive and industrial applications.

Disadvantages:

- Limited lifespan: Although zirconia type lambda sensors are durable, they do have a limited lifespan and will eventually need to be replaced.

- Sensitivity to contaminants: Zirconia type lambda sensors can be sensitive to contaminants, such as oil and coolant, which can affect their accuracy and lifespan.

- High cost: Zirconia type lambda sensors can be more expensive than other types of lambda sensors, such as the titania type.

- Limited application: Zirconia type lambda sensors are not suitable for use in lean-burn engines, where the fuel-to-air ratio is not stoichiometric.

- Slow warm-up time: While zirconia type lambda sensors have a fast response time once they reach their operating temperature, they can take some time to warm up, which can affect their accuracy during this warm-up period.

Overall, the advantages of zirconia type lambda sensors, such as high accuracy, durability, and wide operating range, make them an essential component in modern automotive and industrial applications. However, their limited lifespan, sensitivity to contaminants, and high cost can be disadvantages that need to be considered when choosing a lambda sensor for a particular application.