Valves are essential components in many mechanical systems, including pipelines, engines, and pumps. These devices control the flow of liquids, gases, and other fluids, as well as regulate pressure and temperature. In this blog, we’ll take a closer look at valves and how they work.

What are valves?

A valve is a mechanical device that controls the flow of fluids by opening, closing, or partially obstructing a passage. Valves come in many different shapes and sizes, from simple gate valves to more complex control valves. Some valves are operated manually, while others are automated using electric or pneumatic actuators.

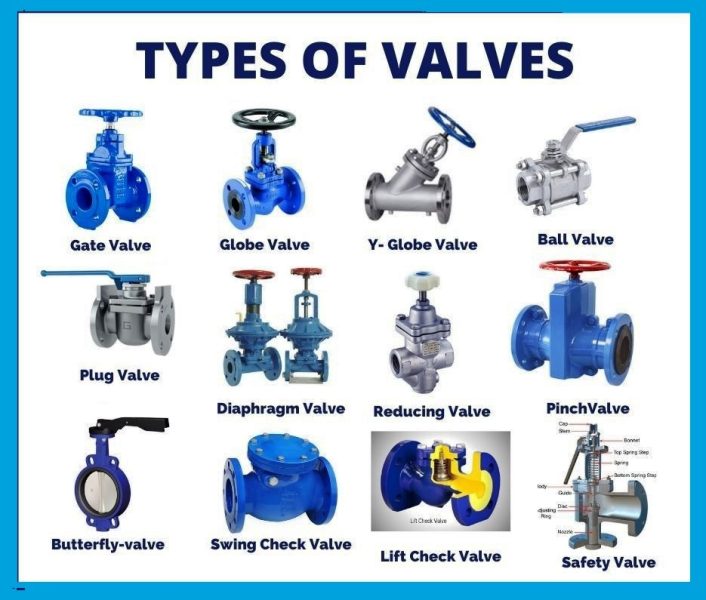

Valve Types

The most common types of valves include:

- Gate valves: These valves have a sliding gate that moves up and down to control the flow of fluids. When the gate is fully open, the fluid can flow freely. When the gate is closed, the flow is stopped entirely.

- Globe valves: These valves have a circular disc that moves up and down to regulate the flow of fluids. Globe valves are often used in applications where precise control is required, such as in steam turbines.

- Ball valves: These valves have a rotating ball with a hole in the middle that allows fluids to flow through. By turning the ball, the flow can be either partially or fully obstructed.

- Butterfly valves: These valves have a disc that rotates to control the flow of fluids. Butterfly valves are often used in applications where rapid opening and closing is required, such as in firefighting systems.

- Check valves: These valves allow fluids to flow in only one direction. When the flow reverses, the valve closes to prevent backflow.

How do valves work?

Valves work by controlling the flow of fluids through a passageway. When a valve is open, the fluid can flow freely. When a valve is closed, the fluid is obstructed, and the flow is stopped.

To open or close a valve, the operator must either manually turn a handle or use an actuator. Actuators are automated devices that can open and close a valve using electric or pneumatic power.

Valves are often designed to regulate pressure and temperature as well. For example, a pressure relief valve is designed to open when the pressure in a system exceeds a certain limit. This allows excess pressure to escape, preventing damage to the system.

Conclusion

Valves are essential components in many mechanical systems. They come in many different types and designs, each with its own specific application. Understanding how valves work is essential for anyone working in fields that rely on these devices. With the right valve selection, you can ensure optimal performance and safety for your mechanical systems.

Applications of valves:

Valves have a wide range of applications across many industries. They are used in industrial processes, such as oil and gas production, chemical processing, and power generation. Valves are also found in residential and commercial buildings, where they are used to regulate the flow of water and gas.

In the oil and gas industry, valves are used to control the flow of crude oil, natural gas, and other fluids in pipelines. Valves are also used to control pressure and temperature in oil and gas wells.

In the chemical processing industry, valves are used to control the flow of chemicals, such as acids, bases, and solvents. Valves are also used to control the temperature and pressure of chemical reactions.

In the power generation industry, valves are used to control the flow of steam, gas, and other fluids in turbines and boilers. Valves are also used to control the flow of cooling water in power plants.

In residential and commercial buildings, valves are used to regulate the flow of water and gas. Valves are also used in HVAC systems to control the flow of air.

Advantages of valves:

The use of valves provides many advantages in mechanical systems. Some of these advantages include:

- Control: Valves provide precise control over the flow of fluids, allowing for optimal performance and safety in mechanical systems.

- Safety: Valves can be used to prevent overpressure, overtemperature, and other dangerous conditions in mechanical systems. This helps to protect personnel and equipment.

- Efficiency: Valves can be used to regulate the flow of fluids, improving efficiency and reducing energy consumption in mechanical systems.

- Durability: Valves are designed to withstand harsh operating conditions, making them durable and long-lasting.

- Flexibility: Valves come in many different types and designs, allowing for a wide range of applications across different industries.

Conclusion:

Valves are essential components in many mechanical systems, providing control, safety, efficiency, durability, and flexibility. Understanding how valves work and selecting the right valve for your application is essential for ensuring optimal performance and safety in your mechanical systems.