So you’ve decided that fuel injection is for you, but you Still Want to know more. Undoubtedly, their area lot of questions surrounding what sparked too many as more Of a black art than science Engine tuning used to be the hallowed ground of vehicle engineers, and the most elite Of Cuthotrodders, For years, the carburetor tilled the needs of enthusiasts and provided simple adjustments at the end Of a flat-bladed screwdriver, AS long as you were willing to spill a little gas, changes to the engines fuel delivery were as close as the toolbox.

Today, stage electronic controls for engines are the norm. Every car coming Off an assembly line in Detroit and around the world uses electronic engine controls. Enthusiasts who have relied upon the trusty carburetor for years now to electronics in search of consistency, convenience, and perhaps those extra few pounds Of torque. Consistency is the primary reason that has driven the OEMs from carburetors to electronic controls since they are required by law to meet Some Very stringent emissions standards today.

The level of precision necessary to achieve these targets just cannot be found with a set of jets, power valves, and accelerator pumps.

But the OEM engineers are not the only ones who stand to benefit from more precise controls. Weekend racers have become progressively more competitive through the years.

The difference between advancing to the next round of eliminations on a Saturday night is often a matter Of a few thousandths of a second. If the weather changes between mid-day.

testing and late-night racing, the precision of a properly tuned electronic fuel injection (EFI) system may be the deciding difference when it counts. Racers are quickly discovering that it’s easier to spend a couple of hours ahead Of time calibrating an electronic controller than it is toscramble for the right jet change between rounds.

Even the casual enthusiast who actually drives his favorite hot rod on the streets can easily see the benefit of increased precision when he fires the car up for the first time each spring. A properly tuned EFI system rarely needs anything more than the turn of the key to coming to life. Likewise, that same finely tuned EFI system requires no changes as the summer heat Of July and August comes with its change in air density. The car simply runs right even into the cool autumn evenings Of the late season. All the while, we find that not only is the car running smoothly, but it’s also getting respectable fuel economy. That’s right, high-power engines are usually efficient ones. All that high- compression, low-pumping losses, and plentiful natural EGR from the lumpy camshaft is actually good for fuel economy. As long as the tuner takes the time to properly map the engine, it should be able to cruise down the road at the optimum air/fuel ratio with proper spark timing. These are the conditions that make for good fuel economy and a more enjoyable overall experience with the vehicle.

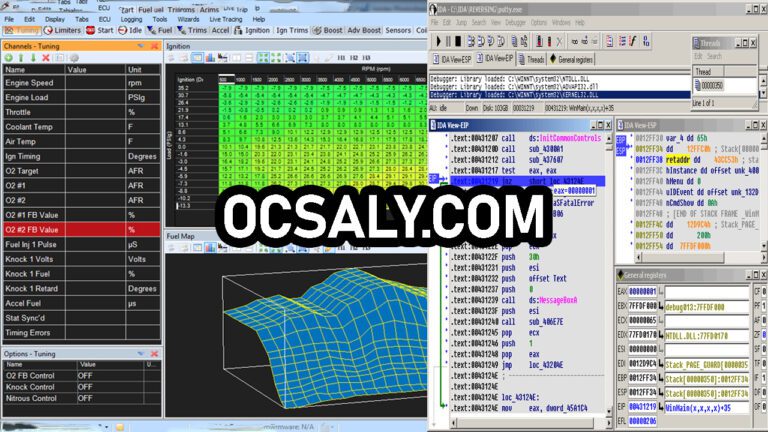

Historically, many professional tuners have regarded their practices as a bit of a secret. Lessons were often learned the hard and slow way, so many were reluctant to share their findings with others in an attempt to maintain their control of a captive market Or position as “the tuning expert.” This cloak of secrecy still exists today in many shops across the country, but these are luckily a dying breed. Knowledge Of electronic fuel injection is rapidly becoming more common among enthusiasts as the market becomes savvy about how each high-performance dollar is spent. The best tuners in the industry today are the ones with nothing to hide. Having trained many Of them and worked side by side with some Of the brightest people in the horsepower industry, I found long ago that collaboration goes a lot further than concealment. There will always be those who do nothing more than copy others’ work and cleverly conceal it as their own. The best in the industry are the ones who can apply the laws of physics and thermodynamics to almost any engine put before them and develop a working calibration based on sound testing results and math. There is no black magic when the numbers line up. Understanding where the numbers come from is the first step, followed closely by practicing the application of this knowledge in a controlled environment.

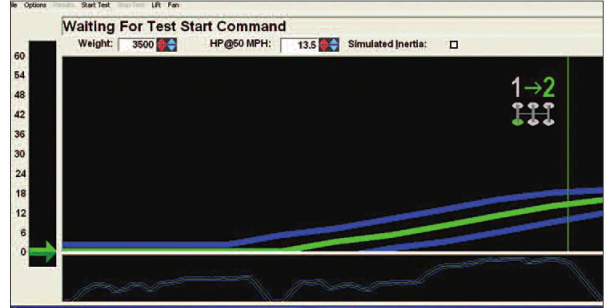

“New production vehicles must pass stringent federal emissions standards before they are legal for sale. The most common test cycle is the FTP72 seen here with its 18 unique “hills” that are meant to replicate typical city conditions.”