The main jet is an important component of the carburetor in an internal combustion engine. It is responsible for controlling the amount of fuel that enters the engine by regulating the flow of fuel from the fuel tank to the venturi. In this blog, we will discuss the main jet in more detail, including its function, construction, and how it affects engine performance.

Function of the Main Jet:

The main jet’s primary function is to regulate the amount of fuel that enters the engine. The fuel flow rate is controlled by the size of the hole in the jet. This size is expressed as a number, which corresponds to the diameter of the hole in thousandths of an inch. For example, a #65 main jet has a hole size of 0.065 inches.

The main jet is responsible for delivering the correct fuel-to-air ratio to the engine. This ratio is critical for engine performance, fuel efficiency, and emissions control. A too-rich mixture can lead to poor fuel economy, fouled spark plugs, and increased emissions. A too-lean mixture can cause engine damage due to overheating or detonation.

Construction of the Main Jet:

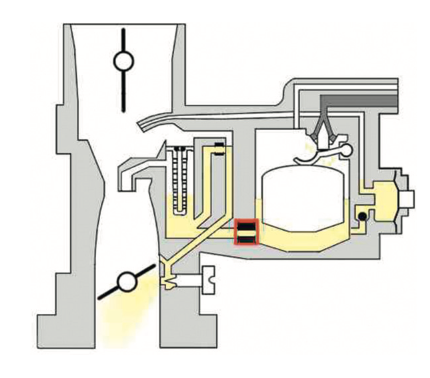

The main jet is typically made of brass and has a threaded body that screws into the carburetor body. It has a small orifice in the center, which allows fuel to flow through it. The size of the orifice determines the amount of fuel that flows through the main jet. The larger the orifice, the more fuel that flows through it.

The main jet can be accessed by removing the carburetor bowl or by removing the carburetor body from the engine. Some carburetors have a removable plug that allows access to the main jet without removing the carburetor.

Effects of Main Jet Size on Engine Performance:

The size of the main jet has a significant effect on engine performance. A larger main jet will allow more fuel to flow through the carburetor, resulting in a richer fuel-to-air ratio. This can increase engine power but may decrease fuel economy and increase emissions.

A smaller main jet will restrict the flow of fuel, resulting in a leaner fuel-to-air ratio. This can decrease engine power but may increase fuel economy and decrease emissions.

The main jet size can be adjusted to optimize engine performance for a specific application. Racing engines, for example, may require a larger main jet to produce more power, while a street engine may require a smaller main jet to optimize fuel economy.

Conclusion:

The main jet is a critical component of the carburetor in an internal combustion engine. It regulates the flow of fuel from the fuel tank to the venturi and controls the fuel-to-air ratio. The size of the main jet affects engine performance, fuel economy, and emissions control. Adjusting the main jet size can optimize engine performance for a specific application.

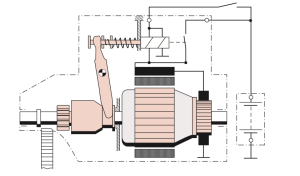

The carburetor is responsible for mixing fuel and air in the correct proportions to provide the engine with the necessary combustion elements. The fuel is stored in the fuel tank and delivered to the carburetor through a fuel line. The carburetor then atomizes the fuel into a fine mist and mixes it with the incoming air.

The main jet is one of the most important components of the carburetor, as it controls the amount of fuel that enters the engine. The main jet is located in the carburetor’s body, near the bottom of the fuel bowl. The fuel bowl is a reservoir that holds a supply of fuel, and the main jet controls how much fuel is drawn from the fuel bowl and into the venturi.

The venturi is a narrow section of the carburetor that creates a vacuum as air flows through it. This vacuum draws fuel from the fuel bowl and into the venturi, where it mixes with the incoming air. The amount of fuel that enters the venturi is controlled by the size of the main jet.

The main jet size is determined by the diameter of the hole that runs through its center. The size of the hole is expressed in thousandths of an inch, and the larger the number, the larger the hole. For example, a #50 main jet has a hole size of 0.050 inches, while a #75 main jet has a hole size of 0.075 inches.

The main jet size affects the air/fuel ratio of the carburetor. A larger main jet allows more fuel to flow into the carburetor, creating a richer air/fuel mixture. This can improve performance, especially at high speeds or under heavy loads, but can also decrease fuel economy and increase emissions.

On the other hand, a smaller main jet restricts the flow of fuel, creating a leaner air/fuel mixture. This can decrease performance but increase fuel economy and decrease emissions.

The main jet size can be changed to adjust the air/fuel ratio of the carburetor for different driving conditions or engine modifications. For example, a larger main jet may be needed for high-performance engines with aftermarket camshafts, intake manifolds, or exhaust systems. Conversely, a smaller main jet may be needed for fuel-efficient driving or engines with lower compression ratios.

In conclusion, the main jet is a critical component of the carburetor system, controlling the flow of fuel to the venturi and affecting the air/fuel ratio of the engine. Its size can be adjusted to optimize engine performance for different driving conditions and engine modifications.

Advantages of Main Jet:

- Improved Engine Performance: The main jet plays a critical role in ensuring the correct fuel-to-air ratio, which is essential for optimal engine performance. A correctly sized main jet can increase engine power and torque, especially at high speeds or under heavy loads.

- Easy to Adjust: Changing the size of the main jet is relatively easy and can be done by anyone with basic mechanical skills. This allows drivers and mechanics to fine-tune the carburetor to suit specific driving conditions or engine modifications.

- Cost-Effective: Compared to other engine modifications that can improve performance, changing the main jet is relatively inexpensive. This makes it an attractive option for drivers who want to improve engine performance without breaking the bank.

- Reliable: Carburetors have been used in internal combustion engines for over a century, and they have a proven track record of reliability. The main jet is a simple mechanical component that rarely fails and can provide years of trouble-free service.

Disadvantages of Main Jet:

- Poor Fuel Economy: A larger main jet can increase engine power but can also decrease fuel economy. This is because a richer air/fuel mixture requires more fuel to be burned, resulting in lower fuel efficiency.

- Increased Emissions: A richer air/fuel mixture can also increase emissions, particularly of carbon monoxide (CO) and hydrocarbons (HC). This can be a problem for drivers who are concerned about their environmental impact or live in areas with strict emissions regulations.

- Limited Adjustment Range: The main jet can only adjust the air/fuel ratio within a certain range. If the desired air/fuel ratio falls outside this range, other modifications to the carburetor or engine may be necessary.

- Difficult to Tune: While changing the main jet is relatively easy, fine-tuning the carburetor for optimal performance can be more challenging. This requires a good understanding of engine mechanics and tuning techniques, which can take time and effort to learn.

In conclusion, the main jet is an essential component of the carburetor system that can improve engine performance and be adjusted to suit specific driving conditions or engine modifications. However, it can also decrease fuel economy, increase emissions, and require skill to fine-tune for optimal performance.