An inductive distributor is a type of ignition system used in internal combustion engines. It is responsible for distributing high voltage electrical energy from the ignition coil to the spark plugs in the correct firing order and at the right time, allowing the engine to run smoothly and efficiently. In this blog, we will discuss in detail what an inductive distributor is, how it works, and its advantages and disadvantages.

What is an inductive distributor?

An inductive distributor is a mechanical device that is used in older vehicles to distribute high voltage electrical energy from the ignition coil to the spark plugs. It is also known as a mechanical distributor. In a typical inductive distributor, a rotating shaft is connected to a camshaft, which opens and closes a set of contact points to control the timing of the spark that ignites the fuel mixture in the engine’s cylinders.

How does an inductive distributor work?

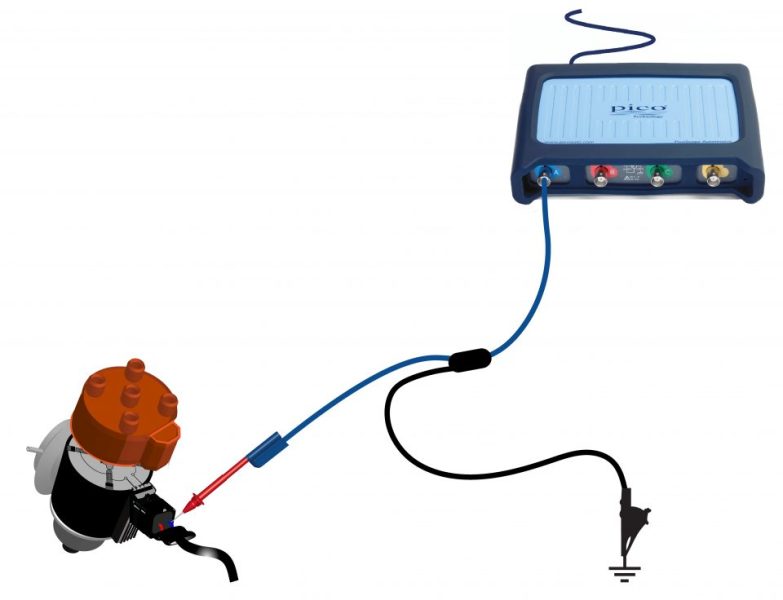

The ignition process in an inductive distributor begins with a 12-volt electrical current supplied by the battery. This current flows through the primary winding of the ignition coil, which creates a magnetic field around the coil. When the contact points in the distributor open, the magnetic field collapses, inducing a high voltage spark that travels through the distributor cap to the spark plugs, igniting the fuel mixture in the engine’s cylinders.

The distributor shaft is driven by the engine’s camshaft through a gear or chain, and it rotates at half the engine speed. As the shaft rotates, a rotor mounted on the top of the shaft turns inside the distributor cap. The rotor has a metal contact that is located close to the terminals in the distributor cap. As the rotor turns, it makes contact with each of the terminals in the cap, sending the high voltage spark to the appropriate spark plug in the firing order.

Advantages of an inductive distributor

One of the main advantages of an inductive distributor is its simplicity. The mechanical design of the distributor is straightforward, making it relatively easy to diagnose and repair. The distributor is also relatively inexpensive to manufacture, making it an attractive option for older vehicles.

Inductive distributors are also robust and reliable. They are designed to last for many years and can withstand harsh operating conditions, such as extreme temperatures and vibrations.

Disadvantages of an inductive distributor

One of the main disadvantages of an inductive distributor is its lack of precision. The mechanical design of the distributor means that it is subject to wear and tear, which can affect the timing of the spark. This can result in poor engine performance, reduced fuel efficiency, and increased emissions.

Another disadvantage of an inductive distributor is its limited ability to deliver high voltage. This can make it challenging to run high-performance engines, as the spark may not be strong enough to ignite the fuel mixture efficiently.

Conclusion

An inductive distributor is a mechanical device that is used to distribute high voltage electrical energy from the ignition coil to the spark plugs in older vehicles. While it is a relatively simple and reliable design, it does have some disadvantages, such as its lack of precision and limited ability to deliver high voltage. Nevertheless, it remains a popular choice for older vehicles and is still widely used in classic car restoration projects.

Inductive distributors were widely used in older vehicles before the development of electronic ignition systems. They were commonly found in vehicles produced before the 1980s and were a standard component in most gasoline-powered engines. Today, electronic ignition systems have largely replaced inductive distributors due to their greater precision and efficiency.

One of the main limitations of inductive distributors is their inability to accurately control the timing of the spark. The opening and closing of the contact points are controlled by a mechanical camshaft, which is subject to wear and tear. This can lead to inaccurate spark timing, which can result in poor engine performance, reduced fuel efficiency, and increased emissions.

Another limitation of inductive distributors is their limited ability to deliver high voltage. The voltage delivered to the spark plugs is limited by the distance between the rotor and the terminals in the distributor cap. This can make it challenging to run high-performance engines, as the spark may not be strong enough to ignite the fuel mixture efficiently.

To overcome these limitations, modern engines use electronic ignition systems that use solid-state electronics to control the timing and voltage of the spark. These systems can deliver a more precise spark timing, which can improve engine performance, fuel efficiency, and reduce emissions.

In summary, while inductive distributors were once a standard component in most gasoline-powered engines, they have been largely replaced by electronic ignition systems in modern vehicles due to their greater precision and efficiency. However, inductive distributors remain a popular choice for classic car restoration projects, and many enthusiasts prefer the simplicity and reliability of these mechanical systems.

Advantages:

- Simplicity: Inductive distributors are a simple mechanical device that is easy to manufacture, maintain, and repair. They do not require any sophisticated electronics, making them a cost-effective option.

- Reliability: Inductive distributors are robust and durable, designed to withstand harsh operating conditions such as extreme temperatures and vibrations. They are known for their longevity and can last for many years without any issues.

- Compatibility: Inductive distributors are compatible with a wide range of engines, making them a popular choice for older vehicles. They are easy to install and can be easily adapted to fit a variety of engines.

Disadvantages:

- Lack of precision: Inductive distributors are subject to wear and tear, which can affect the timing of the spark. This can result in poor engine performance, reduced fuel efficiency, and increased emissions.

- Limited voltage delivery: Inductive distributors have a limited ability to deliver high voltage, which can make it challenging to run high-performance engines. The spark may not be strong enough to ignite the fuel mixture efficiently, which can lead to reduced engine performance.

- Maintenance requirements: Inductive distributors require periodic maintenance, including the replacement of the contact points, cap, and rotor. This can add to the overall cost of ownership and maintenance of the vehicle.

Overall, while inductive distributors are a reliable and cost-effective ignition system, they have some limitations, particularly in terms of precision and voltage delivery. Electronic ignition systems have largely replaced inductive distributors in modern vehicles due to their greater precision and efficiency.