In the world of automobiles, there are various types of ignition systems that have been developed over the years to deliver a spark to ignite the fuel in the engine. One of the most popular and reliable types of ignition systems is the Hall effect distributor. In this blog, we will explore what a Hall effect distributor is, how it works, and what are its advantages over other types of ignition systems.

What is a Hall Effect Distributor?

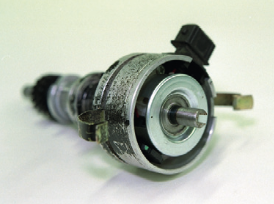

A Hall effect distributor is a type of distributor used in internal combustion engines. It is named after the Hall effect, which is the phenomenon of a magnetic field affecting the flow of electric current in a conductor. In simple terms, the Hall effect is used to detect the position of a rotating part in the engine and then send a signal to the ignition coil to generate a spark at the right time.

How Does a Hall Effect Distributor Work?

The Hall effect distributor has a magnetic sensor that is mounted in the distributor housing. This sensor detects the position of a reluctor wheel, which is mounted on the distributor shaft. The reluctor wheel has evenly spaced teeth that generate a magnetic field as they pass by the sensor. The magnetic field generated by the reluctor wheel is picked up by the sensor, which sends a signal to the engine control module (ECM).

The ECM then uses the signal from the Hall effect sensor to determine the position of the distributor shaft and the timing of the spark. The ignition coil is then triggered at the right time to generate the spark that ignites the fuel in the engine.

Advantages of Hall Effect Distributors

There are several advantages of using a Hall effect distributor over other types of ignition systems. Some of the main advantages are:

- Improved Timing Accuracy: The Hall effect distributor provides improved timing accuracy as compared to other types of distributors. This is because it uses a magnetic sensor to detect the position of the reluctor wheel, which is more accurate than the mechanical systems used in other types of distributors.

- Reduced Maintenance: The Hall effect distributor has fewer moving parts as compared to other types of distributors. This means that it requires less maintenance and has a longer lifespan.

- Better Performance: The Hall effect distributor provides better performance as compared to other types of distributors. This is because it provides a more consistent spark, which results in better engine performance.

Conclusion

In conclusion, the Hall effect distributor is an important component of the ignition system in an internal combustion engine. It provides improved timing accuracy, reduced maintenance, and better performance as compared to other types of distributors. If you are looking for a reliable and efficient ignition system for your vehicle, then the Hall effect distributor is definitely worth considering.

The Hall effect sensor in a Hall effect distributor is a solid-state device that detects the magnetic field generated by the reluctor wheel as it rotates. The sensor consists of a semiconductor material that is sensitive to magnetic fields. When a magnetic field is present, it creates a voltage across the semiconductor material, which is detected by the sensor.

The reluctor wheel in a Hall effect distributor is typically made of a ferromagnetic material, such as iron or steel, and has evenly spaced teeth around its circumference. As the reluctor wheel rotates, the teeth pass by the Hall effect sensor, generating a magnetic field. The sensor detects the changes in the magnetic field and sends a signal to the engine control module (ECM) to determine the position of the distributor shaft and the timing of the spark.

One of the advantages of a Hall effect distributor is that it is more accurate than mechanical distributors. Mechanical distributors rely on a set of points to open and close the circuit to the ignition coil, which can wear out over time and cause the timing to be off. In contrast, a Hall effect distributor uses a solid-state sensor to detect the position of the reluctor wheel, which is more accurate and reliable.

Another advantage of a Hall effect distributor is that it requires less maintenance than mechanical distributors. Mechanical distributors require regular maintenance to keep the points clean and properly adjusted. In contrast, a Hall effect distributor has no points to maintain and requires only periodic inspection of the reluctor wheel and sensor to ensure proper operation.

In summary, the Hall effect distributor is a reliable and efficient ignition system that provides improved timing accuracy, reduced maintenance, and better performance as compared to other types of distributors. Its solid-state design and accurate detection of the position of the reluctor wheel make it a popular choice for internal combustion engines in automobiles and other applications.

Certainly, here are some advantages and disadvantages of the Hall effect distributor:

Advantages:

- Improved Timing Accuracy: The Hall effect distributor provides accurate and precise timing of the ignition system, which results in better engine performance and improved fuel efficiency.

- Reduced Maintenance: The solid-state design of the Hall effect distributor means that there are no moving parts, such as points or rotors, that require regular maintenance. This reduces the need for upkeep and improves the overall reliability of the ignition system.

- Better Performance: The Hall effect distributor provides a more consistent spark, which results in better engine performance and smoother operation.

- Improved Durability: The solid-state design of the Hall effect distributor makes it less susceptible to wear and tear than mechanical distributors, which can extend its lifespan.

Disadvantages:

- Cost: The Hall effect distributor can be more expensive than other types of distributors due to its solid-state design and the use of electronic components.

- Complexity: The Hall effect distributor is more complex than mechanical distributors, which can make it more difficult to diagnose and repair if something goes wrong.

- Sensitivity: The Hall effect sensor is sensitive to magnetic interference and other electrical disturbances, which can cause it to malfunction or provide inaccurate readings.

- Limited Compatibility: The Hall effect distributor may not be compatible with all types of engines, as it requires a specific mounting location and may require modifications to the engine to install.

In summary, the Hall effect distributor provides many advantages over mechanical distributors, including improved accuracy, reduced maintenance, and better performance. However, its complexity, cost, and sensitivity may make it less desirable for some applications. As with any ignition system, it is important to weigh the pros and cons to determine the best option for your specific needs.