Carburetors have been an integral part of the automotive industry for over a century. They are responsible for the air-fuel mixture that powers internal combustion engines. In this blog, we will take a closer look at what a carburetor is, how it works, and its advantages and disadvantages.

What is a Carburetor?

A carburetor is a device that mixes fuel and air in the correct proportions before it enters the engine. In simpler terms, it is the component that helps gasoline engines run by creating the perfect fuel-to-air ratio.

Carburetors work on the principle of Bernoulli’s theorem. According to this theorem, when a fluid (in this case, air) flows through a tube, its pressure decreases as its velocity increases. The carburetor takes advantage of this principle to create a vacuum that pulls air into the engine. Fuel is then mixed with the air to create a combustible mixture that powers the engine.

How does a Carburetor work?

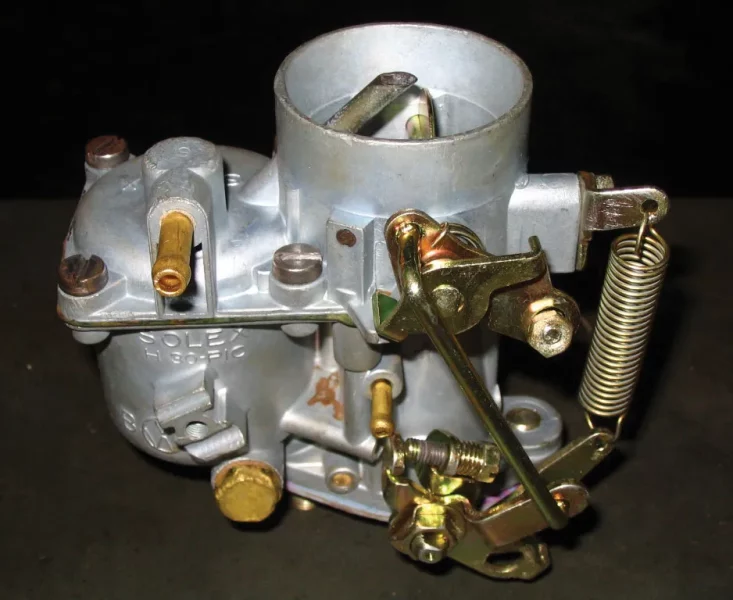

A typical carburetor consists of several parts, including a float chamber, a throttle valve, and a venturi. The float chamber stores fuel and allows it to flow into the carburetor as needed. The throttle valve controls the amount of air that enters the engine, and the venturi is a narrow tube that creates a vacuum and draws in air.

When you start the engine, the carburetor draws in air through the venturi. The air passes through a narrow section of the venturi, where its velocity increases, creating a vacuum. This vacuum then draws fuel from the float chamber through the jets, where it mixes with the air to create a combustible mixture. The amount of fuel that enters the engine depends on the position of the throttle valve. If the valve is partially open, less air enters the engine, and the carburetor delivers less fuel. If the valve is fully open, more air enters the engine, and the carburetor delivers more fuel.

Advantages of Carburetors

Carburetors have several advantages over other fuel delivery systems. For one, they are relatively simple and inexpensive to manufacture and maintain. They are also easy to tune and adjust, allowing mechanics to optimize engine performance for specific applications. Carburetors are also more forgiving of changes in altitude and atmospheric conditions than other fuel delivery systems.

Disadvantages of Carburetors

Despite their advantages, carburetors have several disadvantages. They are not as precise as fuel injection systems, which can deliver a more accurate fuel-to-air ratio. Carburetors can also be affected by changes in temperature and humidity, which can cause the fuel-to-air ratio to change. In addition, carburetors are less efficient than fuel injection systems and can reduce engine power and fuel economy.

Conclusion

Carburetors have been a critical component of the automotive industry for over a century. Although they have several disadvantages, they remain a popular choice for enthusiasts who appreciate their simplicity, adjustability, and affordability. As the automotive industry continues to evolve, carburetors will likely become less common, but their legacy will remain.

Types of Carburetors

There are several types of carburetors, including the updraft, downdraft, and sidedraft carburetors. Updraft carburetors were common in early automobiles, where the carburetor was located above the engine. Downdraft carburetors, which are the most common type, have the carburetor mounted on top of the intake manifold, with the air flowing downward into the engine. Sidedraft carburetors are mounted on the side of the engine and are often used in racing applications.

Components of a Carburetor

Carburetors are composed of several components, including the throttle valve, choke, jets, and float. The throttle valve controls the amount of air entering the engine, while the choke restricts air flow to create a richer mixture during cold starts. The jets control the amount of fuel delivered to the engine, and the float ensures a constant level of fuel in the float chamber.

Tuning a Carburetor

Carburetors require periodic tuning and adjustments to ensure optimal engine performance. Tuning involves adjusting the air-fuel mixture and idle speed to achieve maximum power and efficiency. Carburetor tuning can be a complex process that involves adjusting various components, including the jets, throttle valve, and float. The process often requires a good understanding of engine mechanics and experience in tuning carbureted engines.

Fuel Injection vs. Carburetion

Fuel injection systems have largely replaced carburetors in modern automobiles. Fuel injection systems are more precise and efficient, delivering a more accurate fuel-to-air ratio to the engine. Fuel injection systems are also less affected by changes in altitude and temperature, making them more reliable in a variety of conditions. However, carburetors remain popular in racing and custom applications, where enthusiasts value their simplicity and adjustability.

In conclusion, carburetors have been a critical component of the automotive industry for over a century, providing a simple and reliable means of delivering fuel to the engine. Despite their disadvantages compared to fuel injection systems, carburetors remain popular in certain applications and are still an essential part of automotive history.

Advantages of Carburetors:

- Simplicity: Carburetors are relatively simple in design and construction, which makes them easy to manufacture, install, and maintain.

- Affordability: Carburetors are typically less expensive than fuel injection systems, making them a cost-effective option for many vehicle applications.

- Adjustability: Carburetors are easy to tune and adjust, allowing mechanics to optimize engine performance for specific applications.

- Reliability: Carburetors are generally more forgiving of changes in altitude and atmospheric conditions than fuel injection systems.

- Customizability: Carburetors are popular among racing and custom car enthusiasts because they can be modified and adjusted to provide greater performance and power.

Disadvantages of Carburetors:

- Fuel efficiency: Carburetors are less efficient than fuel injection systems, which can lead to reduced engine power and fuel economy.

- Emissions: Carburetors can produce higher levels of emissions than fuel injection systems, which can make them less environmentally friendly.

- Accuracy: Carburetors are less precise than fuel injection systems in delivering the correct fuel-to-air ratio, which can lead to inconsistent performance.

- Temperature sensitivity: Carburetors can be affected by changes in temperature and humidity, which can cause the fuel-to-air ratio to change.

- Complexity of tuning: Tuning a carburetor requires experience and skill, which can make it challenging for those who are not familiar with engine mechanics.

Overall, carburetors have several advantages and disadvantages, and their use depends on the specific needs and preferences of the vehicle owner. While they are still used in certain applications, fuel injection systems have largely replaced carburetors in modern automobiles due to their increased precision and efficiency.