In earlier engines, viscous-fan hubs were commonly used as a cooling mechanism for the engine. The viscous-fan hub is a mechanical device that is responsible for regulating the amount of air that passes through the radiator and over the engine’s surface. This device is essentially a clutch system that is connected to the engine’s water pump and the fan blades. It uses a viscous fluid, typically silicon oil, to transfer torque from the engine to the fan blades.

The purpose of the viscous-fan hub is to regulate the amount of airflow over the engine’s surface, which helps to control the engine’s temperature. If the engine is running hot, the viscous-fan hub will increase the speed of the fan blades, which will in turn increase the amount of airflow over the engine’s surface. Conversely, if the engine is running cool, the viscous-fan hub will slow down the fan blades to reduce the amount of airflow over the engine’s surface.

The viscous-fan hub is a simple and reliable device, but it does have a few drawbacks. One of the most significant drawbacks is that it can be difficult to diagnose if there is a problem with the system. For example, if the engine is running hot, it could be due to a malfunctioning viscous-fan hub, but it could also be due to a problem with the radiator or water pump.

Another issue with viscous-fan hubs is that they can wear out over time. The silicone oil used in the system can break down and lose its viscosity, which can lead to reduced performance. If the viscous-fan hub is not working correctly, it can cause the engine to overheat, which can lead to engine damage or failure.

In modern engines, viscous-fan hubs have been replaced by electric fans, which are more efficient and reliable. Electric fans are controlled by a computer that monitors the engine’s temperature and adjusts the fan speed accordingly. They also have the advantage of being quieter and consuming less power than traditional viscous-fan hubs.

In summary, the viscous-fan hub is a mechanical device that was commonly used in earlier engines to regulate the amount of airflow over the engine’s surface. While it was a simple and reliable system, it had some drawbacks, including difficulty in diagnosing problems and potential for wear and tear. Today, electric fans have largely replaced viscous-fan hubs due to their increased efficiency and reliability.

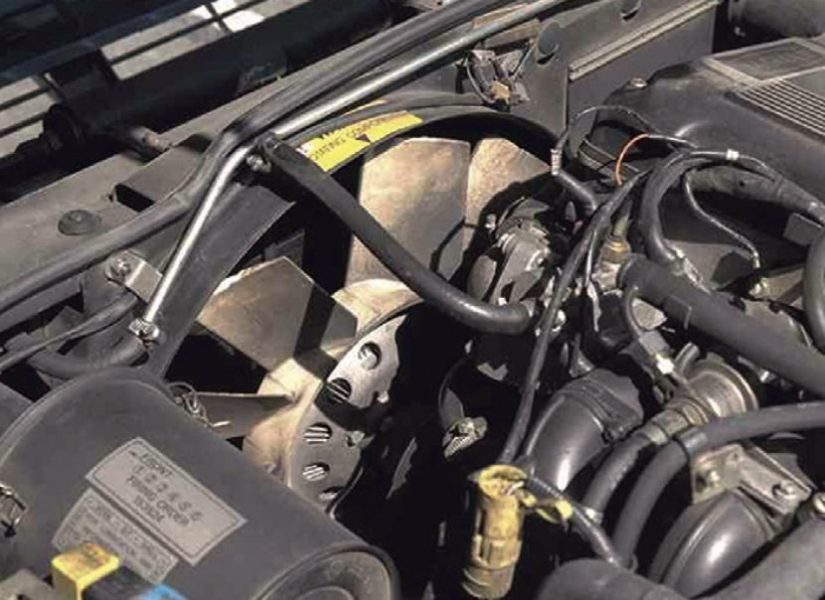

Certainly! To further explain, the viscous-fan hub is typically located at the front of the engine and is attached to the water pump, which is responsible for circulating coolant throughout the engine to regulate its temperature. The hub is also connected to the fan blades, which are housed in a shroud that is positioned behind the radiator.

The hub consists of two parts: a central input shaft that is connected to the water pump, and an outer housing that is connected to the fan blades. The input shaft and outer housing are separated by a viscous fluid, which is typically a silicon oil that has a high viscosity.

When the engine is running, the water pump turns the input shaft, which in turn causes the viscous fluid to heat up and become less viscous. This change in viscosity allows the outer housing to rotate at a faster speed, which increases the speed of the fan blades and results in more air being drawn through the radiator and over the engine.

Conversely, when the engine is running cool, the viscous fluid remains thick and viscous, which limits the amount of torque that is transferred from the input shaft to the outer housing. This causes the fan blades to spin at a slower speed, which reduces the amount of airflow over the engine.

One of the advantages of the viscous-fan hub is that it is a passive system, which means that it doesn’t require any additional electrical or mechanical components to operate. It relies solely on the engine’s rotation and the heat generated by the engine to regulate the fan speed.

However, as mentioned earlier, the viscous-fan hub does have some disadvantages. One of the main drawbacks is that it can be difficult to diagnose if there is a problem with the system, as there are no warning lights or sensors that indicate if the hub is functioning correctly. Another issue is that the viscous fluid can break down over time, which can result in reduced performance and potentially cause the engine to overheat.

In conclusion, while the viscous-fan hub was a reliable and effective cooling mechanism for earlier engines, it has largely been replaced by more advanced and efficient systems in modern engines. Nevertheless, it remains an interesting and important part of the history of engine cooling technology.

Sure, here are some advantages and disadvantages of the viscous-fan hub:

Advantages:

- Simple and reliable: The viscous-fan hub is a passive system that relies on the engine’s rotation and heat to regulate the fan speed, making it a simple and reliable cooling mechanism.

- Cost-effective: Compared to electric fans, the viscous-fan hub is a cost-effective option as it doesn’t require any additional electrical or mechanical components to operate.

- Effective in regulating engine temperature: The viscous-fan hub is effective in regulating the engine temperature as it can increase or decrease the amount of airflow over the engine’s surface depending on the engine’s heat output.

Disadvantages:

- Difficult to diagnose problems: One of the main drawbacks of the viscous-fan hub is that it can be difficult to diagnose problems with the system, as there are no warning lights or sensors that indicate if the hub is functioning correctly.

- Wear and tear: The viscous fluid used in the system can break down over time, which can result in reduced performance and potential engine overheating.

- Less efficient than modern cooling systems: Compared to electric fans and other modern cooling systems, the viscous-fan hub is less efficient and can consume more power, resulting in reduced fuel efficiency.