If you’re in the market for a reliable and efficient pump, you might want to consider a vane pump. Vane pumps are a popular choice for many industries, from automotive to food processing, thanks to their simple design and versatility.

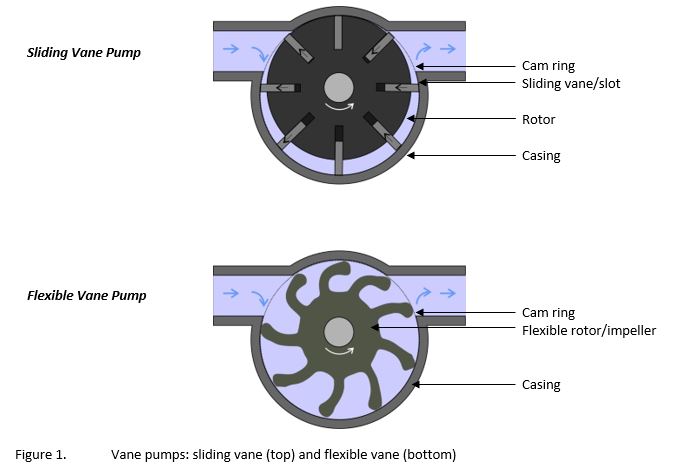

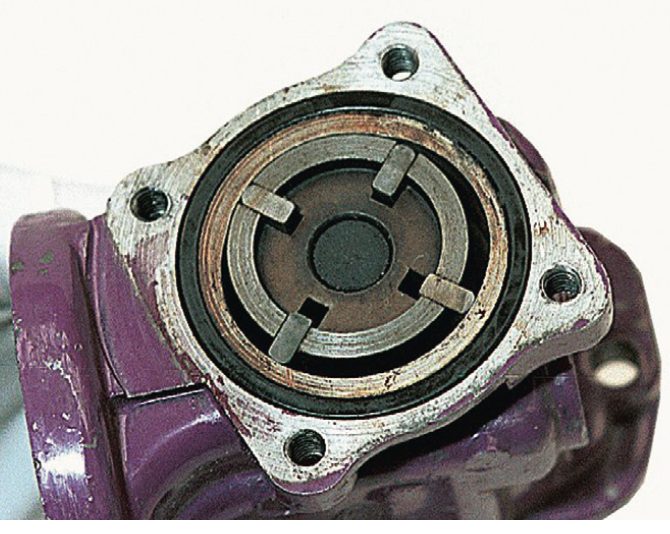

So, what is a vane pump? Simply put, it’s a positive displacement pump that uses vanes to create suction and move fluid through the pump. The vanes are typically made of metal or plastic and are attached to a rotor that spins within a cavity in the pump. As the rotor turns, the vanes slide in and out of the cavity, creating suction and moving the fluid through the pump.

One of the main advantages of vane pumps is their efficiency. Because they are positive displacement pumps, they move a precise amount of fluid with each rotation, making them ideal for applications that require accurate flow rates. They also operate quietly and smoothly, with minimal vibration or pulsation.

Vane pumps are also versatile, with a wide range of materials and configurations available to suit different applications. For example, if you need to pump abrasive fluids, you can choose a vane pump with a hard-coated rotor or ceramic vanes to resist wear and tear. If you need to pump corrosive fluids, you can choose a pump made from materials like stainless steel or plastic that are resistant to chemical damage.

Another benefit of vane pumps is their low maintenance requirements. Because they have few moving parts and operate at low speeds, they are less likely to experience mechanical failures or require frequent repairs. They also have a relatively long lifespan compared to other types of pumps.

Overall, if you’re looking for a reliable, efficient, and versatile pump, a vane pump might be the right choice for you. With their simple design, low maintenance requirements, and ability to handle a wide range of fluids and applications, vane pumps are a smart investment for any business.

One of the key advantages of vane pumps is their ability to handle a wide range of fluids. They can handle viscous fluids, like heavy oils and molasses, as well as thin fluids, like water and solvents. They can also handle liquids with solids in suspension, like sewage and slurry. This versatility makes them a popular choice across many industries, from food processing and pharmaceuticals to agriculture and mining.

Another advantage of vane pumps is their consistent flow rate. Because they are positive displacement pumps, they move a fixed amount of fluid with each rotation, regardless of the pressure or viscosity of the fluid. This makes them ideal for applications where a consistent flow rate is important, such as in chemical processing, where precise measurements are required.

Vane pumps also have a relatively low shear rate, which means they are gentle on the fluid being pumped. This is particularly important in applications where the fluid is sensitive to shear forces, such as in the pharmaceutical or biotech industries.

In terms of maintenance, vane pumps are generally low maintenance, as they have few moving parts and operate at low speeds. They also have a relatively long lifespan compared to other types of pumps, which means you can expect to get many years of use out of a well-maintained vane pump.

Of course, like any pump, vane pumps do have some limitations. They are not ideal for high-pressure applications, as they can struggle to maintain their efficiency at high pressures. They are also not recommended for fluids that contain large particles, as these particles can get trapped between the vanes and the housing, leading to wear and tear.

Overall, vane pumps are a versatile, reliable, and efficient choice for many different applications. Whether you’re in the food processing industry, the mining industry, or any other industry that requires fluid transfer, a vane pump could be the solution you’re looking for.

Advantages:

- Efficient: Vane pumps are positive displacement pumps, meaning they move a precise amount of fluid with each rotation. This makes them ideal for applications that require accurate flow rates.

- Versatile: Vane pumps can handle a wide range of fluids, including viscous and abrasive liquids. They are also available in different materials and configurations to suit different applications.

- Low maintenance: Vane pumps have few moving parts and operate at low speeds, making them less likely to experience mechanical failures or require frequent repairs. They also have a relatively long lifespan compared to other types of pumps.

- Low shear rate: Vane pumps have a relatively low shear rate, which means they are gentle on the fluid being pumped. This is important in applications where the fluid is sensitive to shear forces.

- Smooth and quiet operation: Vane pumps operate smoothly and quietly, with minimal vibration or pulsation.

Disadvantages:

- Limited pressure range: Vane pumps are not ideal for high-pressure applications, as they can struggle to maintain their efficiency at high pressures.

- Limited particle handling: Vane pumps are not recommended for fluids that contain large particles, as these particles can get trapped between the vanes and the housing, leading to wear and tear.

- Limited self-priming ability: Vane pumps may require external priming in certain situations, such as when the fluid is particularly viscous or when the pump is located above the fluid level.

Overall, while vane pumps have some limitations, their versatility, efficiency, and low maintenance requirements make them a popular choice for many different applications.