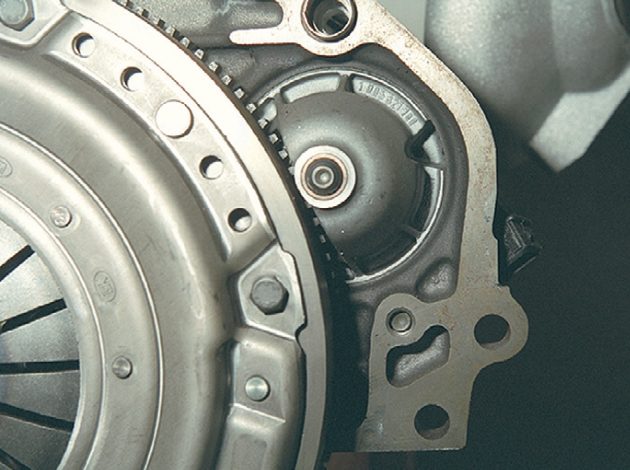

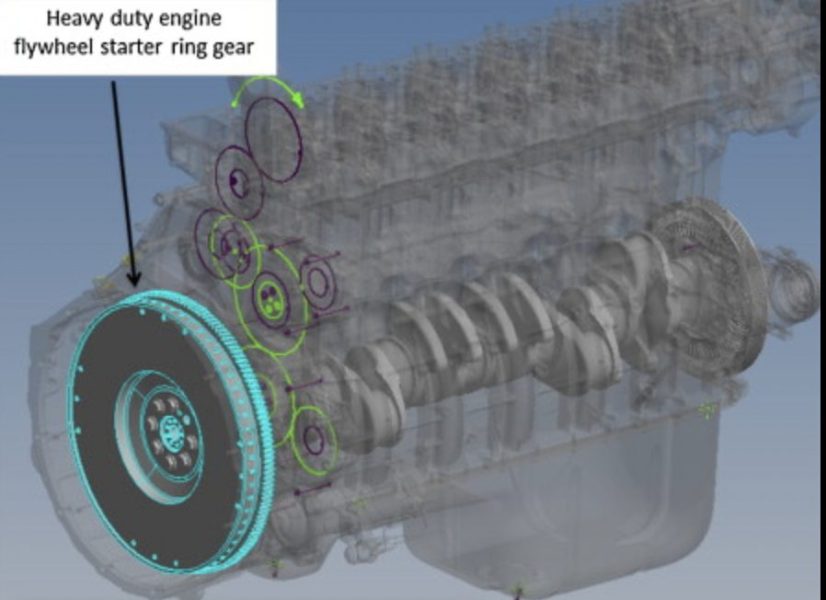

The starter motor is a crucial component in the ignition system of an engine, as it is responsible for starting the engine by cranking the flywheel. The flywheel is a large, heavy wheel mounted on the back of the engine, which serves as a storage device for energy and helps the engine to maintain a steady rotational speed.

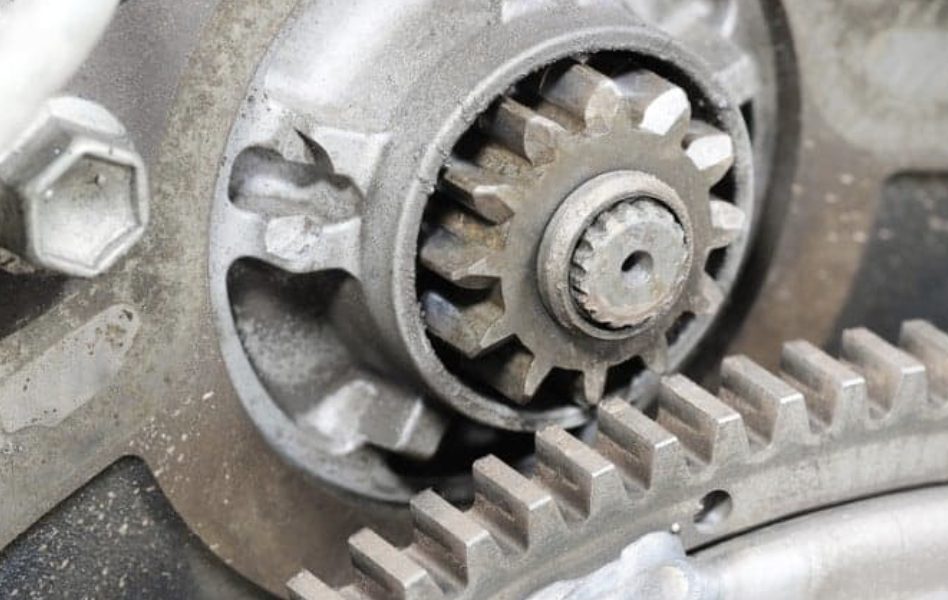

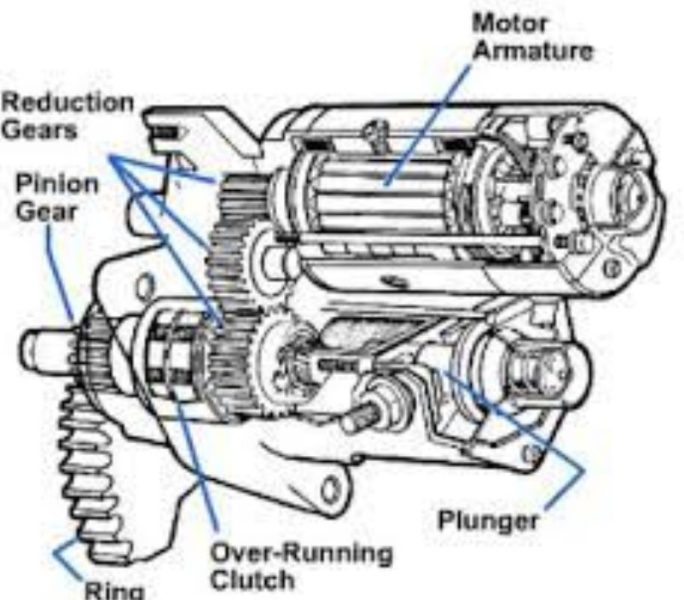

One of the most important components of the starter motor is the starter drive mechanism. This mechanism includes a starter gear, which is designed to mesh with a ring gear on the engine flywheel. When the starter motor is engaged, the starter gear rotates and meshes with the ring gear, causing the flywheel to turn and the engine to start.

The starter gear is typically a small, toothed gear that is attached to the end of the starter motor shaft. It is designed to mesh with the larger ring gear, which is mounted on the edge of the flywheel. The ring gear is typically a large, toothed gear that is bolted onto the flywheel and is positioned around the circumference of the wheel.

The starter gear and the ring gear are designed to engage smoothly and with precision, so that the starter motor can crank the engine without slipping or causing damage to the teeth of either gear. The teeth of the starter gear are usually made of hardened steel, which allows them to withstand the high torque and rotational forces generated by the starter motor.

The ring gear is also designed to be strong and durable, as it must be able to withstand the constant engagement and disengagement with the starter gear during the engine starting process. The ring gear is typically made of cast iron or steel, and is designed to resist wear and damage from the repeated contact with the starter gear.

In order to ensure that the starter gear and the ring gear engage properly, it is important to maintain proper alignment between the two components. This can be achieved by using shims or adjusting the position of the starter motor until the gears are properly aligned. It is also important to ensure that the teeth of both gears are in good condition and free from damage or wear.

In conclusion, the starter gear and the ring gear are essential components of the starter motor system, and are designed to work together in a precise and efficient manner to start the engine. Proper alignment and maintenance of these components is critical for ensuring reliable engine starting and long-term durability of the starter motor system.

Certainly! To expand further, the starter motor is an electric motor that is designed to rotate the engine flywheel and crank the engine to start it. The starter motor is typically located near the bottom of the engine block, and is connected to the flywheel by a drive system that includes the starter gear and the ring gear.

When the ignition switch is turned on, an electric current is sent to the starter solenoid, which in turn activates the starter motor. The motor then rotates the starter gear, which engages with the ring gear on the flywheel and begins to turn the engine over.

The starter motor continues to rotate the flywheel until the engine begins to run on its own, at which point the starter motor is disengaged and the engine takes over. The starter motor is designed to disengage automatically once the engine has started, to prevent damage to the flywheel and starter gear.

In addition to the starter gear and the ring gear, the starter motor also includes a variety of other components, such as the armature, commutator, brushes, and bearings. These components work together to convert electrical energy into mechanical energy, which is used to rotate the starter gear and crank the engine.

It is important to note that the starter motor is not designed to be run continuously, as it can overheat and become damaged if it is operated for an extended period of time. Most modern vehicles include an automatic shutoff feature that disengages the starter motor if it is operated for more than a few seconds at a time.

Overall, the starter motor and its components play a critical role in the starting process of an engine. Proper maintenance and care of these components is essential for reliable engine starting and long-term durability of the starter motor system.

Advantages:

- Convenience: The starter motor system provides a convenient and reliable way to start an engine, allowing the driver to easily and quickly get the vehicle up and running.

- Speed: The starter motor system is designed to start the engine quickly, allowing the driver to get on the road faster.

- Reliability: The starter motor system is generally quite reliable, and can be expected to start the engine with minimal problems or issues.

- Ease of Use: The starter motor system is very easy to use, requiring only the turn of a key or push of a button to start the engine.

- Safety: The starter motor system includes a variety of safety features, such as automatic shutoff and overload protection, that help to prevent damage to the system or the vehicle.

Disadvantages:

- Cost: The starter motor system can be relatively expensive to repair or replace if it fails, particularly in newer vehicles that include more complex systems and components.

- Maintenance: The starter motor system requires regular maintenance and upkeep, such as cleaning and lubrication, to ensure that it continues to operate properly.

- Wear and Tear: The starter motor system can experience wear and tear over time, particularly if it is operated frequently or in harsh conditions, which can lead to decreased performance and reliability.

- Environmental Impact: The starter motor system relies on electricity from the vehicle’s battery, which can have an environmental impact if the battery is not properly maintained or disposed of.

- Complexity: The starter motor system can be quite complex, particularly in newer vehicles that include more advanced electronics and control systems, which can make it more difficult to repair or troubleshoot if issues arise.

Overall, the starter motor system provides a convenient and reliable way to start an engine, but it also has some potential drawbacks that should be considered. Proper maintenance and care of the system can help to minimize these disadvantages and ensure that the starter motor continues to operate effectively and efficiently.