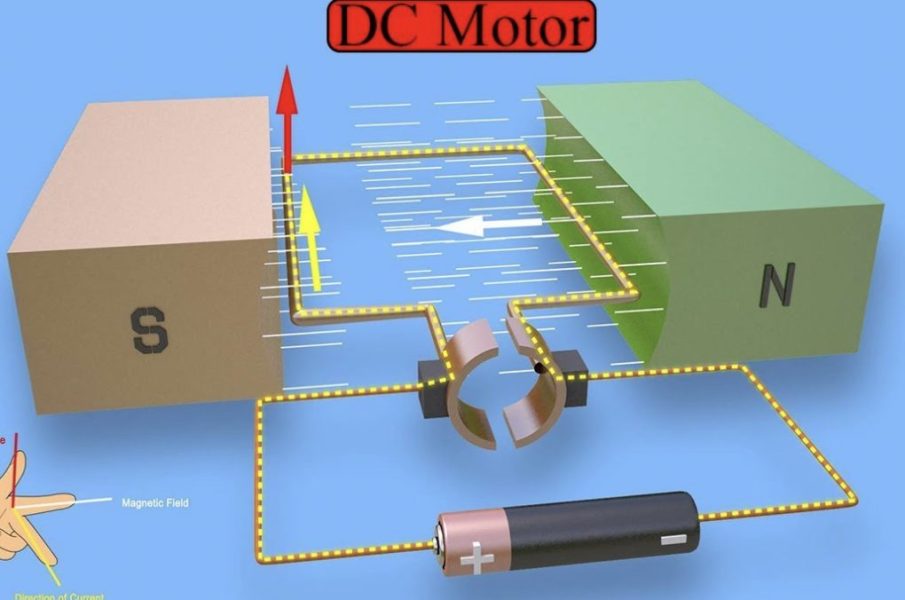

Direct current (DC) motors are widely used in a variety of industrial and commercial applications, including robotics, machinery, and automotive systems. These motors operate on a simple principle: a magnetic field is created around a conductor carrying an electric current, which interacts with the magnetic field generated by a stationary magnet, causing the conductor to rotate.

The basic operating principle of a DC motor is governed by Faraday’s Law of Electromagnetic Induction, which states that a voltage is induced in a conductor when it moves through a magnetic field. In a DC motor, this principle is applied to a rotating armature, which is a cylindrical device with multiple loops of wire wound around it. When current flows through these wires, a magnetic field is created around the armature, which interacts with the magnetic field generated by the stationary magnet, causing the armature to rotate.

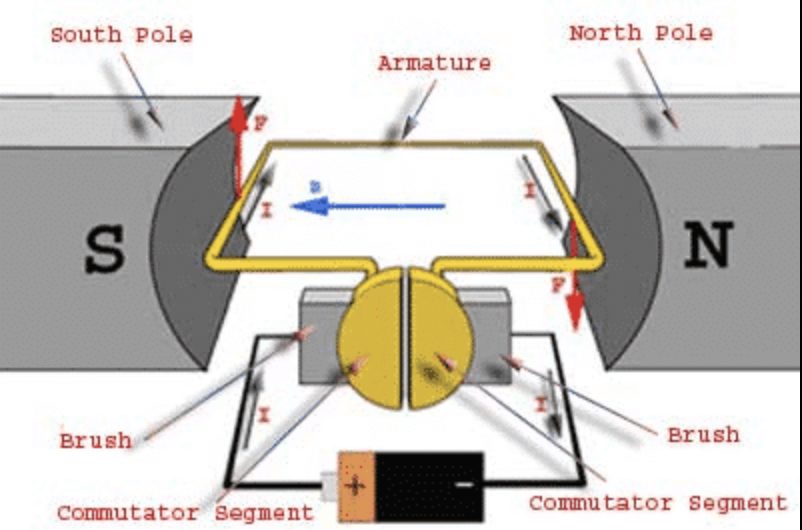

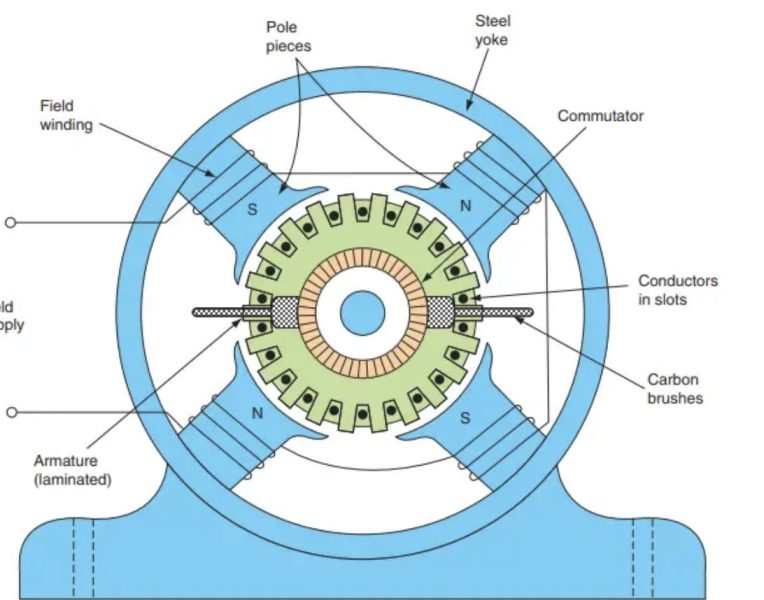

The armature is connected to a commutator, which is a segmented metallic cylinder that rotates along with the armature. The commutator serves to switch the direction of the current flowing through the armature as it rotates, ensuring that the magnetic field around the armature remains in the same direction, and the motor continues to rotate in the same direction. The commutator essentially functions as a mechanical rectifier, converting the AC current supplied to the motor into DC current flowing through the armature.

DC motors come in a variety of designs, but the basic principles of operation remain the same. The most common type of DC motor is the brushed DC motor, which uses brushes made of carbon or graphite to provide electrical contact between the commutator and the external power supply. As the brushes wear down over time, they need to be replaced to ensure proper operation of the motor.

Another type of DC motor is the brushless DC motor, which uses electronic circuitry to switch the direction of the current flowing through the motor without the need for brushes. Brushless DC motors are more efficient and reliable than brushed DC motors, but they are also more expensive.

DC motors are also characterized by their torque-speed characteristics, which describe the relationship between the torque produced by the motor and its rotational speed. DC motors typically have a linear torque-speed curve, meaning that the torque produced by the motor is directly proportional to its rotational speed. This makes DC motors ideal for applications that require precise control of speed and torque, such as robotics and industrial automation.

In conclusion, DC motors operate on the principle of electromagnetic induction, where a magnetic field is created around a conductor carrying an electric current, which interacts with the magnetic field generated by a stationary magnet, causing the conductor to rotate. DC motors come in a variety of designs, including brushed and brushless DC motors, and are characterized by their torque-speed characteristics, making them ideal for applications that require precise control of speed and torque.

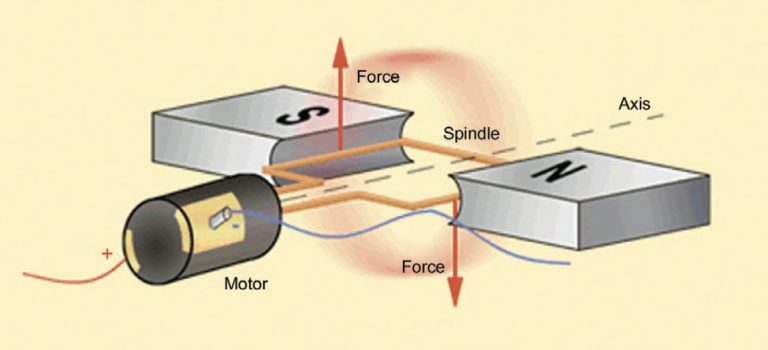

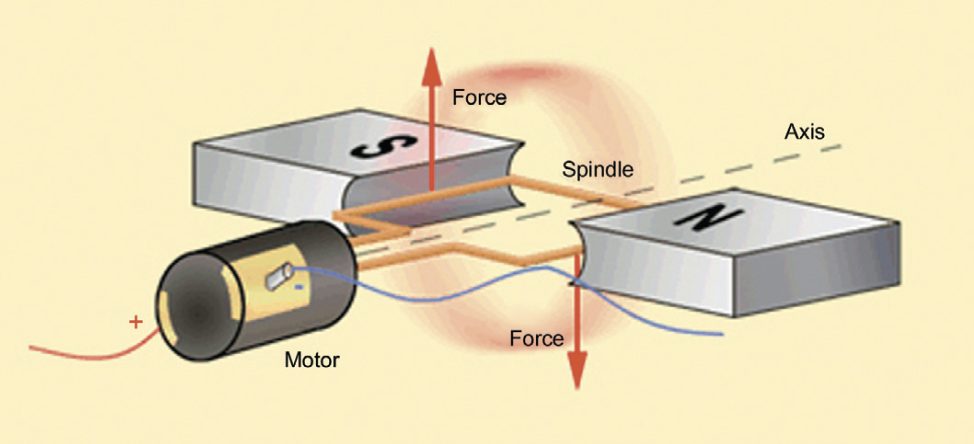

When an electric current flows through a conductor, a magnetic field is generated around the conductor. The direction of this magnetic field is determined by the direction of the current flow, according to the right-hand rule. If you curl your right hand around the conductor with your thumb pointing in the direction of the current flow, your fingers will point in the direction of the magnetic field.

In a DC motor, the conductor is the armature, which consists of multiple loops of wire wound around a cylindrical core. As the armature rotates, the magnetic field around it also rotates. This rotating magnetic field interacts with the magnetic field generated by the stationary magnet, causing a torque to be generated on the armature.

To understand how this torque is generated, consider the interaction between two magnets. When two magnets are brought close together, they will either attract or repel each other, depending on the orientation of their poles. The same principle applies to the interaction between the magnetic field of the armature and the magnetic field of the stationary magnet in a DC motor.

As the armature rotates, the magnetic field it generates interacts with the magnetic field of the stationary magnet, causing the armature to experience a force that is perpendicular to both magnetic fields. This force, called the Lorentz force, generates a torque on the armature that causes it to rotate.

To ensure that the magnetic field around the armature remains in the same direction as it rotates, the direction of the current flowing through the armature needs to be switched every half-turn. This is accomplished by the commutator, which is a segmented metallic cylinder that rotates along with the armature. As the commutator rotates, it switches the connection between the armature and the external power supply, reversing the direction of the current flowing through the armature.

The commutator essentially functions as a mechanical rectifier, converting the AC current supplied to the motor into DC current flowing through the armature. This is necessary because the magnetic field generated by the armature needs to be in the same direction as it rotates to ensure that the motor continues to rotate in the same direction.

DC motors are widely used in a variety of applications because of their simplicity, reliability, and ability to provide precise control of speed and torque. They are also easy to control because the speed of the motor is directly proportional to the voltage applied to it. This makes DC motors ideal for applications such as robotics, industrial automation, and electric vehicles.

Advantages:

- High starting torque: DC motors provide high starting torque, which makes them suitable for applications that require high starting torque, such as cranes, elevators, and hoists.

- Precise speed control: DC motors offer precise control over the speed and torque, making them ideal for applications where speed control is critical, such as in robotics, machinery, and industrial automation.

- Simple design: DC motors have a relatively simple design, which makes them easy to manufacture and maintain.

- Efficient: DC motors are generally more efficient than AC motors, especially at low speeds and light loads.

- Low cost: DC motors are generally less expensive than their AC counterparts.

Disadvantages:

- Brush wear: Brushed DC motors require regular maintenance to replace the brushes, which can wear out over time.

- Limited lifespan: DC motors have a limited lifespan, which can be affected by factors such as the type of application, maintenance, and operating conditions.

- Electromagnetic interference: DC motors can generate electromagnetic interference (EMI) that can affect other electronic devices and equipment.

- Limited speed range: DC motors have a limited speed range, which can make them less suitable for applications that require high speeds.

- Low power density: DC motors have a lower power density than some other types of motors, which can make them less suitable for applications that require high power density.

Overall, DC motors are a popular choice for a wide range of applications due to their simplicity, efficiency, and precise control over speed and torque. However, they do have some limitations, such as brush wear, limited lifespan, and electromagnetic interference, that should be considered when choosing a motor for a specific application.