Who says that power upgrades must be expensive, involved, illegal, and fragile? There’s an old saying in the go-fast world: “Cheap, fast, and

reliable . . . pick any two.” Inexpensive, reliable monster power upgrades are

few and far between, but many simple modifications yield some extra power

without either compromising reliability or forcing you to take a second mortgage on the house.

Combustion Theory

Three critical elements limit your engine’s maximum power output:

Fuel

Spark

Air

The power derived from all three items can be improved with simple bolt-ons.

Increasing airflow (improving the engine’s ability to move air before and after

combustion) usually pays the biggest dividends. The internal combustion

engine is a giant air pump. The more air the engine takes in on the intake side

and pushes out on the exhaust side, the more power it can produce.

What’s going on inside your engine is a series of small, carefully timed explosions. Each explosion requiresThe proper proportion of oxygen and fuel

A spark at just the right time

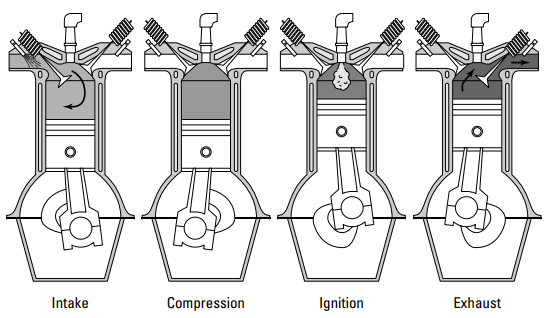

The combustion cycle consists of four distinct actions that happen sequentially inside each cylinder, as illustrated this picture:

Intake: When air and fuel are introduced into the combustion chamber

through the intake valve.

Compression: When the air-fuel mixture is compressed (for a more powerful explosion) prior to combustion.

Ignition: When the spark plug fires a spark to ignite the compressed airfuel mixture.

Exhaust: When the combustion chamber is emptied of exhaust gases

through the exhaust valve.

When tuning your car, it’s best to have control over all three combustion elements (air, fuel, and spark). A change in one element almost always requires a

corresponding set of changes in the others for an increase in consistent and

reliable power:

As you add air, you should be able to add fuel to keep the ratio consistent.

With more air and fuel in the mix, you should be able to control the lightoff point, or ignition point, of the mixture.

Modern cars are adaptive and flexible — within their limits:

When you add a little air to your late model engine, the engine management system changes the fuel delivery and ignition to account for the

change. That is, your car “learns” that something’s different and accounts

for the altered operating parameters. When this adjustment occurs, a

wonderful thing happens — extra power is made!

The engine management system’s learning ability is limited to a range

that’s close to the factory parameters. Most modern cars can account

for changes of 5 to 15 percent in operating parameters. This range is fine

for relatively minor modifications such as bolt-on air intakes, exhaust

components, and upgraded ignitions. But it doesn’t allow your engine to

compensate for 200 percent more air from the turbocharger that magically appeared under the hood one sunny afternoon.

If you (and local law enforcement) don’t mind extra noise, you can easily produce more power by increasing airflow. Most modern cars deliver enough

fuel and spark to use more air. To minimize noise (both inside the cabin and

outside the car), engineers typically reduce the engine’s ability to quickly

bring air in and expel it.

Car Repair – Auto Mechanic Training Masterclass CRTC+ 2021

Air Intake

The designs for performance intake and exhaust follow many of the same

principles. The idea is to keep the gases moving quickly and efficiently before

and after combustion. The more air you bring in and the faster your engine

ingests it, the higher the volume of air it needs to quickly push out again.

Typically, your factory air intake is designed to be quiet and filter extremely

well — meaning that it is very restrictive and impedes an open airflow.

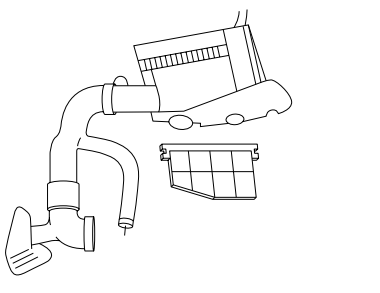

Figure 15-2 illustrates a typical factory air intake. In this image, you can see

the intake box, the replaceable paper air filter, and the restrictive maze of

black plastic tubing that quiets the sound by impeding airflow.

An air intake is a relatively inexpensive and widely available modification for

most cars. An open-element air intake upgrade is usually the first performance

modification that most enthusiasts add to their cars — for good reasons:

Installation is easy.

An open-element performance air filter creates a pleasing sporty induction sound.

Open-element performance air filters reduce the maze of plastic tubing

and boxes in the factory intake plumbing, giving a cleaner appearance

under the hood.

The mod is easily reversible.

It eliminates the need for replacement paper filters.

The engine gains additional power:

• A normally aspirated car gains up to eight horsepower over a particularly restrictive factory intake.

• Turbocharged and supercharged cars may add up to 15 horsepower from an intake alone.

The car gets better gas mileage. Normally aspirated, turbocharged, and

supercharged cars can expect a noticeable improvement — usually a

couple miles per gallon — which often covers the cost of the intake over

time.

You get a more exciting performance from the car. Even cars that gain

only a couple horsepower feel like they gained more with the improvement in throttle response and sound.

Check the CFMs (cubic feet per minute, a measure of flow capacity) dictated

by the size of your turbo, intercooler, air-metering device, and/or throttle

body. Many manufacturers keep these specs on file after testing their filter

elements on a flow bench. By verifying that your filter flows the appropriate

number of CFMs for your turbo’s or engine’s breathing requirements, you can

avoid starving your engine of the air that it needs. If your turbo flows 600

CFM and your intercooler can support as much as 800 CFM, it does you no

good to have a filter element that limits you to 300 CFM.

If you’re running a turbo, check with the manufacturer of your turbo kit to

ensure that the intake you intend to use provides the necessary air mass for

your turbocharger. Failing to feed your turbocharger with as much air as it

needs is likely to greatly shorten its life span.

There are several ways to upgrade your car’s ability to breathe and make

more power:

Drop in a performance air filter.

Add an open-element air intake.

Add a freer-flowing intake manifold and/or throttle body.

Put in more aggressive intake and exhaust camshafts.

The following subsections take a closer look at each of these upgrades.

Open-element air intake

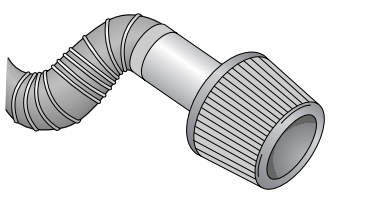

An open-element air intake takes up where the drop-in air filter element leaves

off: It essentially goes straight to the root of the problem — the convoluted

maze of factory intake piping and resonators — and eliminates it entirely in

favor of a shorter and more direct means of feeding air into the turbo or throttle

body/intake manifold. By using either a cotton/gauze cone filter, a mushroomstyle foam filter, or a hybrid filter element attached to a large diameter pipe

aimed at a location in the engine bay that sees significant volumes of fresh air

movement, the open-element air intake helps your engine breathe more easily.

The factory air intake plumbing restricts the engine’s ability to breathe freely —

a common analogy for the situation is that it’s like trying to run a marathon

while breathing through a straw. Eliminate the restrictive factory air intake

plumbing by adding an open-element air intake, and imagine how much better

your engine can pull in air and make power.

An open-element air intake will generally help with throttle response and,

perhaps more so than outright power gains, add a pleasing (to most enthusiasts’ ears) induction sound to the engine under acceleration. An air intake

can also significantly clean up the under-hood appearance of your car and

make it easier to see and access components of your engine bay.

However, as with any performance modification, there are risks and trade-offs

involved. Some trade-offs include the fact that many open-element intakes

will draw in air that is not properly shielded from under-hood heat, thus

reducing overall power instead of adding to it — you need cold air to see

power gains. Nearly all of these intakes also do a worse job of filtering out

dirt than do the factory units. It may not be a catastrophic difference, and in

the long run, the extra dirt may or may not be significant.

Some intakes also let in rain if they’re positioned low in the engine bay where

they may be subject to splashback (or even submersion) during a heavy

downpour, virtually guaranteeing engine damage. Lastly, these open-element

filters are highly visible and may or may not subject you to scrutiny from

local emissions authorities or your local dealership service center.

Three major design constraints in an open-element air intake need to be

accounted for in order to make power:

Filter material

Location

Piping

Filter materials

You find three basic groupings of air filtration elements in open-air intakes:

Cotton/gauze filters

Foam filters

Hybrid filters

Cotton/gauze filters

Pleated cotton/gauze filters, as pioneered and popularized by K&N, are the

most common open-element air intakes on the market. They’re also known as

cone filters because of a common shape, but they’re just as often available in

barrel or cylinder shapes. In this fuigure illustrates a typical cone filter installed.

Note that the piping leading to the throttle body is much shorter than the factory piping was.

Cotton/gauze filters stop a comparable amount of contaminants compared to

disposable a paper element filter while flowing much more air than a disposable paper filter. Some cotton/gauze filters require periodic cleaning and

oiling with a special tacky oil that holds dirt and dust at the filter’s surface.

When using a cotton/gauze filter element that requires oiling, a dirty filter

actually stops more particles than one that’s brand new. The particulate

matter builds up on its surface and keeps the finer particles from being

pulled through the pleats. However, a dirty filter flows less air than a new or

freshly cleaned filter element.

Foam filters

Mushroom-style foam filters, as shown in Figure 15-5 (note the mushroom-like

shape), have been popularized by the HKS green filters. Foam filters often flow

more air than most cotton/gauze filters, but they also allow more contaminants

into the engine than do cotton/gauze filters of similar size and orientation.

Hybrid filters

Hybrid filters combine two filtering mediums. There are a couple of combinations on the market:

ITG uses a dual-density foam element. A loose density (more free-flowing) outer layer of foam covers a denser inner foam element; it looks like

a foam version of the traditional cotton/gauze cone filter. You can see

the two different densities of foam in Figure 15-6.

The dual-density elements provide the best of both worlds by combining

the superior flow of a mushroom-style foam filter (as compared to a traditional cotton/gauze filter) with filtration similar to that of a cotton/gauze

filter.

Other companies place a foam slipcover over traditional cotton/gauze

filters. This is a highly ineffective method of trying to create a hybrid

filter element because the resulting filter is even more restrictive than a

traditional cotton/gauze filter. The use of these slipcovers is best left to

the serious off road crowd.

Hybrid filters are more restrictive than either a mushroom or traditional cone

filter because air must pass through both layers before it enters the intake

pipe.

Location

An open-element air intake needs to be located where it can get plenty of

cold air and also stay relatively dry and clean to protect your engine from

dirt and water. For this reason, many performance open-element air intake

kits position the filter element near forward-facing openings in the car’s grill

or bodywork so that they are exposed to a steady supply of cool air when the

car is moving.

If any part of the intake system (especially the filter) is located near the hot

side of a turbo, or immediately adjacent to the exhaust manifold or down pipe,

it should come with some kind of shielding or shroud to prevent radiant heat

from raising the temperature of the air entering the intake. Unfortunately, many

air intakes use metal pipes (which absorb and retain heat) and unshielded

filter elements. The cooler the air is, the denser it is. Keeping the air cool

allows for more oxygen to be drawn into the engine, so cooler air ultimately

means more power. Plan on making the appropriate modifications to keep the

intake charge cool if you’re considering an intake that doesn’t

Use a silicone or rubber pipe (instead of a metal one)

Provide heat shielding

When shopping for an open-element filter to replace your factory intake

plumbing, be wary of any intake that places the filter at a low or otherwise

exposed point in the engine bay. For example, many performance enthusiasts

will eliminate the factory fog light and use the hole left in the front valence as

a spot for drawing in fresh air. While this forward-facing location is optimal

from an airflow perspective, it also all but ensures that water will be sucked

into the engine when you’re driving in inclement conditions. Your openelement filter shouldn’t be located where it’s likely to pull in water if you get

caught in a heavy downpour or drive through a small snowdrift. Water doesn’t

compress like air, so engine parts may bend or break when trying to compress the water (a phenomenon called hydrolock). Although air bypass kits

are offered by companies like AEM to prevent hydrolocking your engine, it’s a

much better idea to simply place the filter in a location that avoids the risk

entirely. Look for a source of fresh and constantly circulating air, but don’t go

overboard. If your filter element is jammed into the car’s bodywork just

inches from the ground, odds are you’ll be in trouble if the car is ever driven

in heavy rain.

Piping

Air likes to move in a straight line. Air slows down as it is forced to take turns

(particularly tight ones). For this reason, pipes that route air should

Be as straight as possible, with smooth, gradual bends

Avoid excessive length or tapering before reaching the throttle body or

air metering device.

Some intake pipes feature a chamber to store air just before the throttle body.

Factory air intake tracts often feature such chambered air pockets, so there’s

reason to believe that they can be functional, if only to reduce intake noise. The

jury is out on whether stored air can also increase airflow for performance.

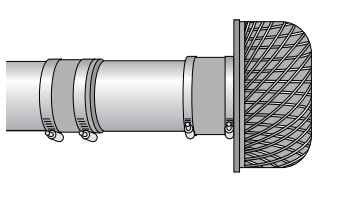

Avoid sharp transitions anywhere in the pipe. Ideally, the path of the air

stream should transition smoothly as it proceeds from the intake into the

engine. If the size of the intake changes, the change should be gradual instead

of sharp. Sharp lips in the pipe cause turbulence in the airstream. Watch out

for these problem areas:

A lip where the aftermarket (not from the car’s original manufacturer)

intake pipe meets the stock throttle body or air metering device

A sudden step down from an excessively large pipe into a narrower factory inlet

illustrates an excessively sharp transition in sizing coupled with a

bend in the pipe — this combination would create turbulence in the airflow,

slowing the velocity of the intake charge.