Oil drilling is a complex and important process that involves the extraction of oil from deep within the earth’s crust. It is a critical activity that is essential to the functioning of the modern world, as oil is used to power everything from cars to airplanes to factories. One of the key components of oil drilling is the valve gear, which plays a crucial role in regulating the flow of oil and gas during the drilling process.

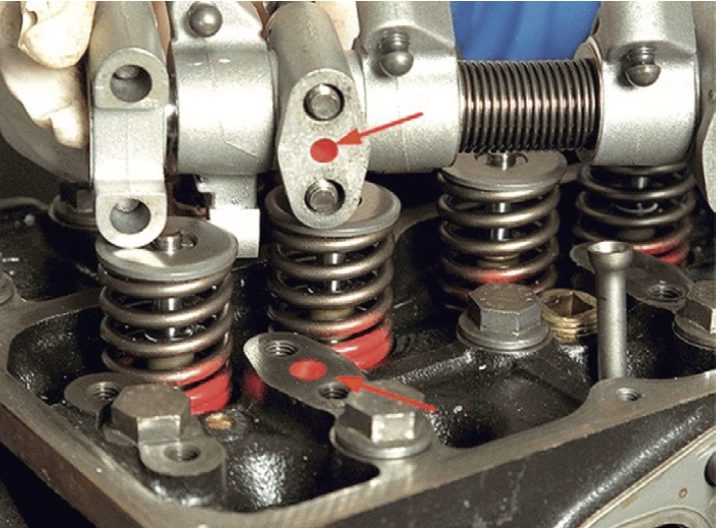

Valve gear is a term used to describe the mechanical devices that control the flow of fluids through pipes or tubes. In the context of oil drilling, valve gear is used to control the flow of oil and gas as it is extracted from the ground. This process is critical because it allows drill operators to manage the pressure and flow rate of the oil and gas, which is necessary to maintain the integrity of the drilling equipment and ensure the safety of the workers.

There are a variety of valve gear systems that are used in oil drilling, each with its own advantages and disadvantages. Some of the most commonly used valve gear systems include gate valves, ball valves, butterfly valves, and plug valves. Gate valves are typically used in situations where a large volume of oil or gas needs to be moved quickly, while ball valves are used in situations where precision control is required. Butterfly valves are used in situations where a combination of speed and precision is necessary, and plug valves are used in situations where the flow of oil or gas needs to be completely shut off.

Regardless of the type of valve gear that is used, oil drilling is an incredibly important process that requires careful attention to detail and a high degree of expertise. It is a challenging field that requires a combination of engineering skill, scientific knowledge, and a deep understanding of the physical properties of oil and gas. However, for those who are interested in pursuing a career in oil drilling, the rewards can be substantial.

In addition to the technical and scientific aspects of oil drilling, there are also many economic and geopolitical factors to consider. The demand for oil and gas is constantly increasing, and as the world’s population continues to grow, this demand is only going to continue to rise. This means that there will always be a need for skilled professionals who are able to extract oil and gas from the earth’s crust in a safe and efficient manner.

Overall, oil drilling and valve gear is a fascinating field that is essential to the functioning of the modern world. It requires a high degree of skill and expertise, but for those who are willing to put in the hard work, the rewards can be substantial. So if you are interested in pursuing a career in oil drilling, then there has never been a better time to get started.

Oil drilling is the process of extracting oil from beneath the earth’s surface. This process typically involves drilling a well into the ground and then using various techniques to extract the oil and gas from the reservoirs below. The oil is then transported to refineries, where it is processed into usable products such as gasoline, diesel fuel, and other petrochemicals.

Valve gear plays a critical role in oil drilling because it helps to regulate the flow of oil and gas during the drilling process. Without proper valve gear, the pressure and flow rate of the oil and gas could become unmanageable, which could lead to serious safety issues and equipment failures.

There are many different types of valve gear that are used in oil drilling. One of the most common types is the gate valve, which is a type of valve that is designed to be fully open or fully closed. Gate valves are typically used when a large volume of oil or gas needs to be moved quickly.

Another common type of valve gear is the ball valve, which is a type of valve that uses a ball-shaped disk to regulate the flow of oil and gas. Ball valves are highly precise and are typically used when precise control is necessary.

Butterfly valves are another type of valve gear that are commonly used in oil drilling. These valves are designed to be highly efficient, combining the speed of gate valves with the precision of ball valves. Butterfly valves are often used in situations where a combination of speed and precision is necessary.

Finally, plug valves are a type of valve gear that are used to completely shut off the flow of oil and gas. These valves are typically used in emergency situations or when equipment needs to be repaired or replaced.

In order to operate valve gear in oil drilling, skilled professionals are required. These professionals are typically highly trained engineers and technicians who have a deep understanding of the physical properties of oil and gas and the equipment used to extract them.

In conclusion, oil drilling and valve gear are critical components of the modern world. They provide the fuel and energy necessary to power our cars, airplanes, factories, and homes. While the field of oil drilling can be challenging and complex, it offers many opportunities for those who are willing to put in the hard work and dedication required to succeed.

Advantages of Oil Drilling and Valve Gear:

- Provides Energy: Oil drilling and valve gear provide the world with a significant portion of its energy needs. Oil is a crucial component of many industries, including transportation, manufacturing, and agriculture.

- Job Creation: Oil drilling and valve gear industries provide employment to millions of people around the world. These jobs range from entry-level positions to highly skilled technical and engineering jobs.

- Economic Benefits: Oil drilling and valve gear industries generate significant revenues for countries that produce oil. These revenues can be used to fund public services such as healthcare, education, and infrastructure.

- Technological Advancements: Oil drilling and valve gear industries are constantly developing new technologies and techniques to improve efficiency and safety. This has led to significant advancements in other industries, such as robotics, materials science, and renewable energy.

Disadvantages of Oil Drilling and Valve Gear:

- Environmental Impacts: Oil drilling and valve gear have significant environmental impacts, including pollution, habitat destruction, and oil spills. These impacts can be long-lasting and difficult to remediate.

- Climate Change: The use of oil as a primary source of energy is a major contributor to climate change. The extraction, transportation, and use of oil release greenhouse gases that contribute to global warming and climate instability.

- Safety Risks: Oil drilling and valve gear can be dangerous and lead to accidents, such as explosions, fires, and toxic gas releases. These accidents can cause serious injury or death to workers and nearby communities.

- Dependence on Fossil Fuels: The reliance on fossil fuels such as oil can limit investment in renewable energy sources and inhibit the development of sustainable energy solutions.

In conclusion, oil drilling and valve gear have both advantages and disadvantages. While they are a critical component of the world’s energy needs and provide significant economic benefits, they also have significant environmental impacts, contribute to climate change, and present safety risks to workers and communities. It is important to continue to develop new technologies and solutions to mitigate the negative impacts of oil drilling and valve gear while also investing in renewable energy sources for a more sustainable future.