Mechanical fuel pumps are a type of fuel delivery system that have been used in gasoline-powered vehicles for decades. They are typically found in older vehicles, as modern cars often use electronic fuel injection systems instead. In this blog, we will explore the mechanics of mechanical fuel pumps, how they work, and their advantages and disadvantages.

What is a Mechanical Fuel Pump?

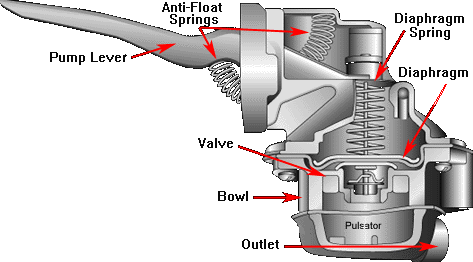

A mechanical fuel pump is a pump that is driven by a camshaft or other mechanical means to draw fuel from the fuel tank and deliver it to the carburetor or fuel injection system of an internal combustion engine. The pump is typically located on the engine block and consists of a housing, diaphragm, and check valves.

How Does a Mechanical Fuel Pump Work?

The mechanical fuel pump is connected to the engine via a camshaft, which drives a lever that in turn moves the diaphragm inside the pump. As the diaphragm moves, it creates a vacuum that draws fuel from the fuel tank and pushes it through the pump and into the carburetor or fuel injection system.

The fuel pump is equipped with check valves that allow the fuel to flow in one direction only, preventing backflow or loss of fuel pressure. One check valve is located on the inlet side of the pump, and the other is located on the outlet side.

Advantages of Mechanical Fuel Pumps

One of the main advantages of mechanical fuel pumps is their simplicity. They do not require any electronics or complex sensors, which makes them easy to maintain and repair. They are also less expensive than electronic fuel injection systems and can provide reliable fuel delivery in a wide range of operating conditions.

Another advantage of mechanical fuel pumps is their ability to deliver fuel at high pressure. This is important in high-performance engines, where a high fuel pressure is necessary to provide the optimal air/fuel mixture for combustion.

Disadvantages of Mechanical Fuel Pumps

One of the main disadvantages of mechanical fuel pumps is their reliance on the engine’s camshaft or other mechanical means to drive the pump. This means that they may not be as efficient as electronic fuel injection systems, which can adjust fuel delivery based on real-time engine conditions.

Mechanical fuel pumps also have a limited flow rate, which means that they may not be suitable for high-horsepower engines or vehicles that require a lot of fuel flow. They can also be susceptible to vapor lock in hot weather, which can cause the fuel to vaporize and prevent the pump from delivering fuel to the engine.

Conclusion

Mechanical fuel pumps have been a reliable and simple fuel delivery system for decades. They are still used in some older vehicles and high-performance applications, but electronic fuel injection systems have largely replaced them in modern cars. While mechanical fuel pumps have their advantages, their reliance on mechanical means and limited flow rate make them less efficient than electronic systems in many cases.

Mechanical fuel pumps are typically driven by the engine’s camshaft, which is located inside the engine block. The camshaft rotates as the engine runs, and a lever or rocker arm attached to the camshaft moves up and down. This motion is transferred to the diaphragm inside the fuel pump, which creates a vacuum that draws fuel into the pump from the fuel tank.

Once the fuel enters the pump, it is pushed through a series of check valves and delivered to the carburetor or fuel injection system at the appropriate pressure. The fuel pressure is regulated by a spring inside the fuel pump, which controls the amount of pressure needed to push the fuel through the system.

One of the main advantages of mechanical fuel pumps is their simplicity. They do not require any electrical or electronic components, which makes them easy to maintain and repair. They also tend to be less expensive than electronic fuel injection systems, which can make them an attractive option for older vehicles or vehicles that do not require high-performance fuel delivery.

However, there are also some disadvantages to mechanical fuel pumps. One of the main disadvantages is their limited flow rate, which can make them less suitable for high-horsepower engines or vehicles that require a lot of fuel flow. This is because the pump is driven by the engine’s camshaft, which may not be able to deliver enough power to move large volumes of fuel quickly.

Another disadvantage of mechanical fuel pumps is their susceptibility to vapor lock in hot weather. Vapor lock occurs when the fuel in the pump and fuel lines becomes so hot that it vaporizes, creating air pockets that prevent fuel from flowing properly. This can cause the engine to stall or not start at all.

In contrast, electronic fuel injection systems are able to adjust the fuel delivery based on real-time engine conditions, making them more efficient and responsive than mechanical fuel pumps. They are also less susceptible to vapor lock, as they use an electric fuel pump that is not affected by the temperature of the engine.

Overall, mechanical fuel pumps have been a reliable and effective fuel delivery system for many years. While they may not be as efficient or high-performing as electronic fuel injection systems, they remain a viable option for some older vehicles or high-performance applications.

Advantages of Mechanical Fuel Pumps:

- Simplicity: One of the main advantages of mechanical fuel pumps is their simplicity. They do not require any electronics or complex sensors, making them easy to maintain and repair.

- Cost-effective: Mechanical fuel pumps are generally less expensive than electronic fuel injection systems. This can make them an attractive option for older vehicles or vehicles that do not require high-performance fuel delivery.

- High-pressure fuel delivery: Mechanical fuel pumps are capable of delivering fuel at high pressure, making them suitable for high-performance engines.

- Compatibility: Mechanical fuel pumps can provide reliable fuel delivery in a wide range of operating conditions, making them compatible with a variety of gasoline-powered engines.

Disadvantages of Mechanical Fuel Pumps:

- Limited flow rate: One of the main disadvantages of mechanical fuel pumps is their limited flow rate. They may not be suitable for high-horsepower engines or vehicles that require a lot of fuel flow.

- Reliance on engine mechanics: Mechanical fuel pumps rely on the engine’s camshaft or other mechanical means to drive the pump. This can make them less efficient than electronic fuel injection systems, which can adjust fuel delivery based on real-time engine conditions.

- Susceptibility to vapor lock: Mechanical fuel pumps can be susceptible to vapor lock in hot weather. Vapor lock occurs when the fuel in the pump and fuel lines becomes so hot that it vaporizes, creating air pockets that prevent fuel from flowing properly.

- Difficulty in starting: Mechanical fuel pumps can be difficult to start in cold weather because the fuel can become thick and viscous, making it harder to pump.

In summary, mechanical fuel pumps have been a reliable and effective fuel delivery system for many years, and they remain a viable option for some older vehicles or high-performance applications. However, they have some limitations compared to electronic fuel injection systems, including their limited flow rate, reliance on engine mechanics, susceptibility to vapor lock, and difficulty in starting in cold weather.