Closed loop control with a lambda sensor is an advanced automotive technology that has revolutionized the way modern engines function. In this blog, we will explore the basics of closed loop control with a lambda sensor, its advantages, and how it works.

What is closed loop control with a lambda sensor?

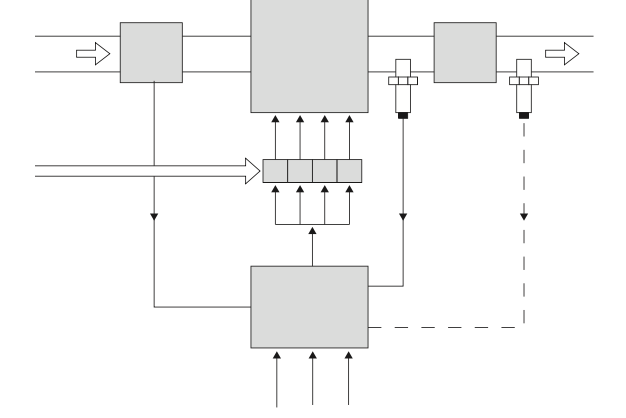

In simple terms, closed loop control is a system that continuously monitors and adjusts the input variables to maintain a desired output. In the case of an engine, the input variables are fuel and air, while the output is the exhaust gas emissions.

A lambda sensor is a device that is used to measure the amount of oxygen in the exhaust gas. It is also known as an oxygen sensor. The lambda sensor provides feedback to the engine control unit (ECU) about the oxygen content in the exhaust gas.

Closed loop control with a lambda sensor involves the ECU using this feedback to adjust the fuel injection and air intake to maintain the ideal air-fuel ratio (AFR) for the engine. The ideal AFR is typically around 14.7:1, meaning 14.7 parts of air to 1 part of fuel. By maintaining this ideal AFR, the engine is able to operate at maximum efficiency, resulting in reduced emissions and improved fuel economy.

Advantages of closed loop control with a lambda sensor

The use of closed loop control with a lambda sensor has several advantages:

- Improved fuel economy: By maintaining the ideal AFR, the engine is able to operate at maximum efficiency, resulting in improved fuel economy.

- Reduced emissions: By maintaining the ideal AFR, the engine produces fewer harmful emissions, such as carbon monoxide and nitrogen oxide.

- Improved engine performance: By adjusting the fuel injection and air intake, the engine is able to operate at its optimal performance level.

- Improved reliability: By continuously monitoring and adjusting the engine parameters, closed loop control with a lambda sensor helps to ensure that the engine is running smoothly and reliably.

How closed loop control with a lambda sensor works

The lambda sensor is located in the exhaust system, downstream of the engine. As the exhaust gas passes over the lambda sensor, it measures the amount of oxygen in the gas. The lambda sensor then sends a signal to the ECU indicating the oxygen content of the exhaust gas.

The ECU then uses this feedback to adjust the fuel injection and air intake to maintain the ideal AFR. If the oxygen content in the exhaust gas is too high, indicating that there is too much air in the mixture, the ECU will reduce the amount of air in the mixture by adjusting the throttle or fuel injection. If the oxygen content is too low, indicating that there is too much fuel in the mixture, the ECU will reduce the amount of fuel in the mixture by adjusting the fuel injection.

This continuous monitoring and adjustment of the engine parameters ensures that the engine is always operating at maximum efficiency, resulting in improved fuel economy, reduced emissions, and improved engine performance.

In conclusion, closed loop control with a lambda sensor is an important technology that has revolutionized the way modern engines function. By continuously monitoring and adjusting the engine parameters, it helps to ensure that the engine is always operating at maximum efficiency, resulting in improved fuel economy, reduced emissions, and improved engine performance.

Closed loop control with a lambda sensor is a highly advanced and precise system that plays a crucial role in modern engines. The lambda sensor is responsible for measuring the oxygen content in the exhaust gas and providing feedback to the engine control unit (ECU) so that it can adjust the air-fuel mixture to maintain the ideal air-fuel ratio (AFR).

The ideal AFR for gasoline engines is around 14.7:1, which means that there are 14.7 parts of air to 1 part of fuel. Maintaining this ideal AFR is essential for the engine to operate at maximum efficiency, which results in reduced emissions and improved fuel economy.

The lambda sensor is typically located in the exhaust system, downstream of the engine. As the exhaust gas passes over the lambda sensor, it measures the amount of oxygen in the gas. The lambda sensor then sends a signal to the ECU indicating the oxygen content of the exhaust gas.

The ECU uses this feedback to adjust the air-fuel mixture by adjusting the fuel injection and air intake. If the oxygen content in the exhaust gas is too high, indicating that there is too much air in the mixture, the ECU will reduce the amount of air in the mixture by adjusting the throttle or fuel injection. If the oxygen content is too low, indicating that there is too much fuel in the mixture, the ECU will reduce the amount of fuel in the mixture by adjusting the fuel injection.

This continuous monitoring and adjustment of the engine parameters ensure that the engine is always operating at maximum efficiency, resulting in improved fuel economy, reduced emissions, and improved engine performance.

Closed loop control with a lambda sensor is not just limited to gasoline engines. Diesel engines also use a similar system known as exhaust gas recirculation (EGR). EGR involves recirculating a portion of the exhaust gas back into the intake air to reduce nitrogen oxide emissions. Like closed loop control with a lambda sensor, EGR also involves continuous monitoring and adjustment to maintain the ideal AFR for the engine.

In conclusion, closed loop control with a lambda sensor is a critical system that has revolutionized the way modern engines function. By continuously monitoring and adjusting the engine parameters, it helps to ensure that the engine is always operating at maximum efficiency, resulting in improved fuel economy, reduced emissions, and improved engine performance. This system is essential for meeting increasingly stringent emissions regulations and improving the overall performance of modern engines.

Advantages of Closed Loop Control with a Lambda Sensor:

- Improved Fuel Economy: By continuously adjusting the air-fuel mixture to maintain the ideal AFR, closed loop control with a lambda sensor can improve fuel economy. This is because the engine is operating at maximum efficiency, resulting in less fuel consumption.

- Reduced Emissions: Closed loop control with a lambda sensor can reduce harmful emissions from the engine, such as carbon monoxide and nitrogen oxide. By maintaining the ideal AFR, the engine is producing less exhaust gas, which is less harmful to the environment.

- Improved Engine Performance: Closed loop control with a lambda sensor helps to improve engine performance by ensuring that the engine is operating at its optimal level. This can result in better acceleration, smoother running, and overall improved engine performance.

- Improved Reliability: By continuously monitoring and adjusting the engine parameters, closed loop control with a lambda sensor can help to improve the reliability of the engine. This is because the system ensures that the engine is running smoothly and efficiently, which reduces wear and tear on the engine components.

Disadvantages of Closed Loop Control with a Lambda Sensor:

- Cost: Closed loop control with a lambda sensor can be expensive, particularly for older vehicles that may not have been designed with this technology in mind. Retrofitting an older vehicle with this technology can be costly and may not be feasible for some owners.

- Complexity: Closed loop control with a lambda sensor is a complex system that requires sophisticated sensors, computer systems, and control algorithms. This complexity can make repairs and maintenance more difficult, and can also increase the cost of replacement parts.

- Performance Tradeoffs: Closed loop control with a lambda sensor may require some tradeoffs in engine performance. For example, the system may prioritize emissions reduction over performance, which could result in reduced power output.

- Maintenance Requirements: The lambda sensor and other components of the closed loop control system require regular maintenance to ensure proper operation. Failure to maintain these components can result in decreased efficiency, reduced engine performance, and increased emissions.

In conclusion, closed loop control with a lambda sensor has several advantages, including improved fuel economy, reduced emissions, improved engine performance, and improved reliability. However, there are also some disadvantages, including cost, complexity, performance tradeoffs, and maintenance requirements. Overall, the benefits of this technology typically outweigh the drawbacks, and closed loop control with a lambda sensor is an important component of modern engines.