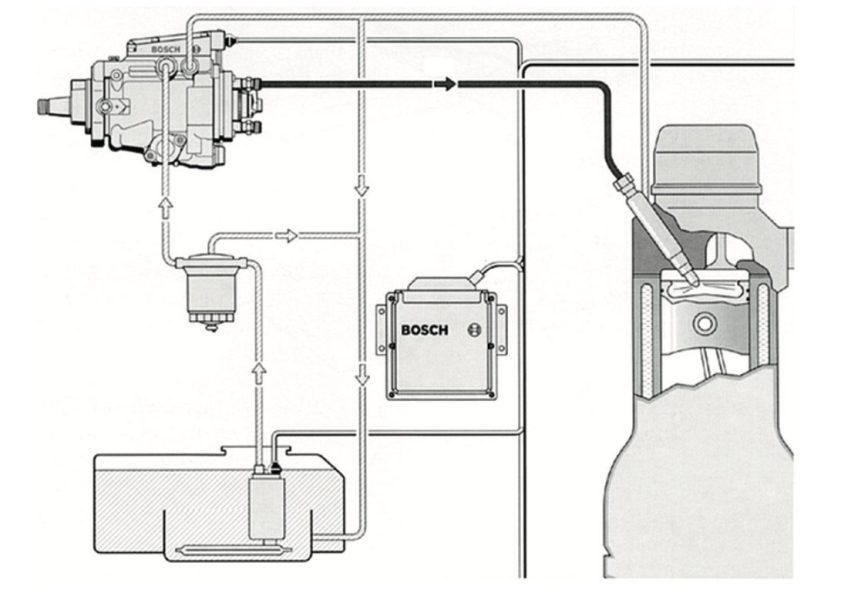

Fuel systems are an essential component of modern engines, enabling efficient combustion and optimal performance. Fuel systems can be broadly classified into two categories: low-pressure systems and high-pressure systems. In this blog, we will discuss the key differences between low-pressure (white and grey) and high-pressure (in black) fuel systems.

Low-pressure fuel system:

A low-pressure fuel system is typically used in carbureted engines, which rely on a vacuum to draw fuel into the engine’s intake manifold. Low-pressure fuel systems are also used in older fuel-injected engines, where the fuel pressure is regulated to a maximum of around 60 psi.

In a low-pressure fuel system, fuel is drawn from the fuel tank by a fuel pump, which is typically located near the tank. The fuel is then filtered before being sent to the carburetor or fuel injectors. In carbureted engines, the fuel is mixed with air in the carburetor before being delivered to the engine’s intake manifold. In fuel-injected engines, the fuel is delivered directly to the engine’s combustion chambers through the fuel injectors.

Low-pressure fuel systems are relatively simple and inexpensive compared to high-pressure fuel systems. However, they can be less efficient and may not provide the same level of performance as high-pressure fuel systems.

High-pressure fuel system:

High-pressure fuel systems are typically used in modern fuel-injected engines, where the fuel is delivered at a much higher pressure than in low-pressure systems. High-pressure fuel systems can deliver fuel at pressures of up to 2,000 psi or more.

In a high-pressure fuel system, fuel is drawn from the fuel tank by a high-pressure fuel pump, which is typically located in or near the engine. The fuel is then filtered and sent to the fuel rail, which is a high-pressure pipe that delivers fuel to the fuel injectors. The fuel injectors then deliver precise amounts of fuel directly into the engine’s combustion chambers.

High-pressure fuel systems are more efficient than low-pressure systems, as they can deliver precise amounts of fuel at high pressures, which enables more complete combustion and optimal performance. However, they are also more complex and expensive than low-pressure systems.

White and grey fuel system:

White and grey fuel systems are low-pressure fuel systems used in marine engines. White systems are typically used in gasoline-powered engines, while grey systems are used in diesel-powered engines. These systems are designed to prevent the risk of explosion or fire on board a vessel.

In a white or grey fuel system, the fuel tank is located outside the engine compartment, and the fuel is drawn into the engine through a low-pressure fuel pump. The fuel is then filtered and delivered to the carburetor or fuel injectors, depending on the engine type.

White and grey fuel systems are designed to be safe and reliable, but they may not provide the same level of performance as high-pressure fuel systems.

In conclusion, fuel systems are an essential component of modern engines, and they come in a variety of types, including low-pressure (white and grey) and high-pressure (in black) fuel systems. While low-pressure systems are relatively simple and inexpensive, high-pressure systems are more efficient and provide optimal performance. The choice of fuel system depends on the engine type and application, and it’s important to choose the right system to ensure optimal performance and safety.

Low-pressure fuel systems are typically used in older engines or in carbureted engines. They operate at a fuel pressure of around 60 psi or less. In these systems, fuel is drawn from the fuel tank by a fuel pump, which is typically located near the fuel tank. The fuel is then filtered and delivered to the carburetor or fuel injectors, depending on the engine type.

Carbureted engines mix the fuel with air in the carburetor before delivering it to the engine’s combustion chambers. This method of fuel delivery is less precise than fuel injection, which is why carbureted engines tend to have lower fuel efficiency and produce more emissions.

Fuel-injected engines, on the other hand, deliver fuel directly to the engine’s combustion chambers through the fuel injectors. The fuel is pressurized before being injected into the combustion chamber, which ensures a precise and efficient fuel delivery. However, older fuel-injected engines still operate at low pressures, which can limit their performance compared to modern high-pressure fuel systems.

High-pressure fuel systems are typically used in modern fuel-injected engines. These systems operate at much higher fuel pressures than low-pressure systems, typically ranging from 500 to 2,000 psi or more. High-pressure fuel systems can deliver precise amounts of fuel at high pressures, which enables more complete combustion and optimal performance.

In high-pressure fuel systems, fuel is drawn from the fuel tank by a high-pressure fuel pump, which is typically located in or near the engine. The fuel is then filtered and delivered to the fuel rail, which is a high-pressure pipe that delivers fuel to the fuel injectors. The fuel injectors then deliver precise amounts of fuel directly into the engine’s combustion chambers.

The advantages of high-pressure fuel systems include improved fuel efficiency, better engine performance, and reduced emissions. However, high-pressure fuel systems are more complex and expensive than low-pressure systems. They require more components, such as a high-pressure fuel pump, fuel rail, and fuel injectors, which can increase the cost of the engine.

White and grey fuel systems are low-pressure fuel systems used in marine engines. These systems are designed to prevent the risk of explosion or fire on board a vessel. In a white or grey fuel system, the fuel tank is located outside the engine compartment, and the fuel is drawn into the engine through a low-pressure fuel pump. The fuel is then filtered and delivered to the carburetor or fuel injectors, depending on the engine type.

In conclusion, the choice of fuel system depends on the engine type and application. Low-pressure fuel systems are simpler and less expensive, but they may not provide the same level of performance as high-pressure fuel systems. High-pressure fuel systems are more complex and expensive, but they offer improved fuel efficiency, better engine performance, and reduced emissions. White and grey fuel systems are designed for marine engines and provide additional safety measures to prevent the risk of explosion or fire.

Advantages of low-pressure fuel systems:

- Simpler and less expensive compared to high-pressure fuel systems.

- Suitable for older engines and carbureted engines.

- Low-pressure fuel systems are less complex, making them easier to maintain and repair.

Disadvantages of low-pressure fuel systems:

- Less precise fuel delivery compared to high-pressure fuel systems.

- Lower fuel efficiency and higher emissions due to less precise fuel delivery.

- Limited performance compared to high-pressure fuel systems.

Advantages of high-pressure fuel systems:

- More precise fuel delivery for optimal engine performance and improved fuel efficiency.

- Reduced emissions due to more complete combustion of fuel.

- Better suited for modern, fuel-injected engines.

Disadvantages of high-pressure fuel systems:

- More complex and expensive compared to low-pressure fuel systems.

- More components can mean more points of failure and higher repair costs.

- High-pressure fuel systems require specialized equipment and training for maintenance and repair.

Advantages of white and grey fuel systems:

- Additional safety measures to prevent the risk of explosion or fire on board a vessel.

- The fuel tank is located outside of the engine compartment, reducing the risk of fuel vapors entering the engine compartment.

Disadvantages of white and grey fuel systems:

- Designed specifically for marine engines and may not be suitable for other applications.

- The additional safety measures can increase the complexity and cost of the fuel system.

- The location of the fuel tank outside the engine compartment can increase the length of fuel lines and the potential for fuel leaks.