Electronic Diesel Control (EDC) is a highly sophisticated electronic system that is used to control and monitor the operation of diesel engines. It is an essential component of modern diesel engines, which rely on precise control of fuel injection and engine management systems to deliver optimal performance, fuel efficiency, and emissions control. In this blog, we will explore the key features and benefits of Electronic Diesel Control.

The basic function of an EDC system is to monitor the various parameters of the diesel engine, such as engine speed, temperature, and pressure, and use this information to control the amount and timing of fuel injection. This allows the engine to operate at maximum efficiency and power output while minimizing emissions. EDC systems also provide diagnostic capabilities that can be used to troubleshoot problems and optimize engine performance.

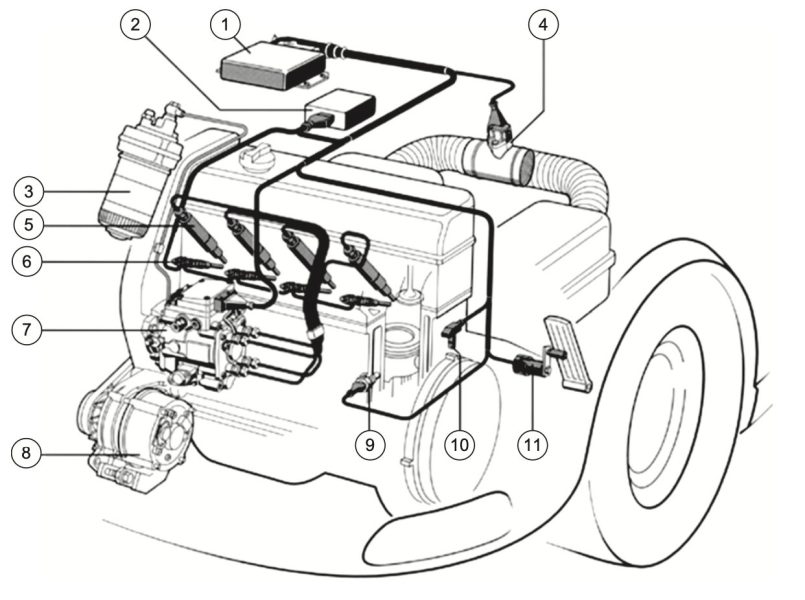

The key components of an EDC system include the engine control unit (ECU), which is the main computer that controls the engine, as well as various sensors and actuators that monitor and control engine operation. The ECU receives input from sensors that measure engine parameters such as the engine speed, temperature, and pressure. It then uses this information to determine the optimum fuel injection timing and amount, as well as other engine functions such as exhaust gas recirculation (EGR) and turbocharger operation.

One of the key benefits of an EDC system is improved fuel efficiency. By precisely controlling fuel injection timing and amount, the EDC system can optimize engine performance and reduce fuel consumption. This not only reduces operating costs but also reduces emissions of harmful pollutants such as nitrogen oxides (NOx) and particulate matter (PM).

Another benefit of EDC is improved engine performance. By monitoring and controlling engine parameters, the EDC system can optimize engine power output and torque. This can lead to improved acceleration, towing capacity, and overall vehicle performance.

EDC systems also provide diagnostic capabilities that can be used to troubleshoot engine problems. By monitoring engine performance and detecting any faults or errors, the EDC system can provide valuable information to technicians, helping them to quickly identify and repair issues before they become more serious.

In conclusion, Electronic Diesel Control is a vital component of modern diesel engines. It provides precise control of fuel injection and engine management systems, which can improve fuel efficiency, reduce emissions, and optimize engine performance. With the increasing demand for more efficient and environmentally friendly diesel engines, EDC systems will continue to play a critical role in the development of next-generation diesel engines.

Sure! Electronic Diesel Control (EDC) systems are used in modern diesel engines to precisely control the fuel injection process and other engine management functions. The EDC system uses a complex set of sensors, actuators, and control algorithms to ensure that the engine operates at peak efficiency while meeting emission standards. Here are some more details about the key features and components of EDC:

- Fuel injection control: EDC systems are designed to precisely control the amount and timing of fuel injected into the engine cylinders. This is done by measuring various engine parameters such as engine speed, load, and temperature, and using this information to calculate the optimum fuel injection parameters. The EDC system then sends signals to the fuel injectors to control the fuel flow rate and timing.

- Engine management functions: In addition to fuel injection control, EDC systems also control other engine management functions such as exhaust gas recirculation (EGR), turbocharger operation, and after-treatment systems. These functions are essential for optimizing engine performance and reducing emissions.

- Sensors: EDC systems rely on a range of sensors to monitor engine parameters such as engine speed, load, temperature, and pressure. These sensors provide real-time feedback to the ECU, which uses this information to make decisions about fuel injection and other engine management functions.

- Actuators: In addition to sensors, EDC systems also use actuators to control various engine functions. For example, the EDC system may use an actuator to control the position of the variable geometry turbocharger or the EGR valve.

- Control algorithms: EDC systems use sophisticated control algorithms to process the input from sensors and make decisions about fuel injection and other engine management functions. These algorithms are designed to optimize engine performance and reduce emissions while minimizing fuel consumption.

Overall, Electronic Diesel Control is a highly advanced system that plays a critical role in modern diesel engines. By providing precise control of fuel injection and other engine management functions, EDC systems help to improve fuel efficiency, reduce emissions, and optimize engine performance. As diesel engines continue to evolve, EDC systems will play an increasingly important role in ensuring that these engines meet the demanding requirements of modern vehicles and industrial applications.

Advantages of Electronic Diesel Control (EDC):

- Improved fuel efficiency: EDC systems can precisely control the fuel injection process, which leads to improved fuel efficiency and reduced operating costs.

- Optimized engine performance: By monitoring and controlling engine parameters, EDC systems can optimize engine performance and improve acceleration, towing capacity, and overall vehicle performance.

- Reduced emissions: EDC systems can help reduce emissions of harmful pollutants such as nitrogen oxides (NOx) and particulate matter (PM) by controlling fuel injection and other engine management functions.

- Diagnostic capabilities: EDC systems provide diagnostic capabilities that can be used to troubleshoot engine problems and optimize engine performance.

- Enhanced safety: EDC systems can help prevent engine damage by monitoring engine parameters and preventing unsafe conditions from occurring.

Disadvantages of Electronic Diesel Control (EDC):

- Complexity: EDC systems are highly complex and require specialized knowledge and training to maintain and repair. This can result in higher maintenance and repair costs.

- Cost: EDC systems are more expensive than traditional diesel engine systems due to the additional components and advanced technology required.

- Dependence on electronics: EDC systems rely heavily on electronics and software, which can be vulnerable to malfunctions and cybersecurity threats.

- Limited compatibility: EDC systems may not be compatible with older diesel engine models, which can limit their applicability in certain settings.

- Need for skilled technicians: Because of the complexity of EDC systems, skilled technicians are required to maintain and repair these systems, which can be a challenge in some locations.

In conclusion, while Electronic Diesel Control (EDC) offers numerous benefits such as improved fuel efficiency, optimized engine performance, and reduced emissions, it also has its disadvantages, including increased complexity, higher cost, and dependence on electronics. As with any technology, the advantages and disadvantages of EDC must be carefully considered when evaluating its suitability for a particular application.