High-pressure pumps are used in a wide range of applications, from industrial to residential, and are designed to pump fluids at high pressures. These pumps are used to move fluids from one place to another, and they are essential for many industries, including oil and gas, manufacturing, and food processing. In this blog, we’ll take a closer look at high-pressure pumps, how they work, and their applications.

What is a high-pressure pump?

A high-pressure pump is a type of pump that is designed to move fluids at high pressures. These pumps are often used in applications where high pressure is required, such as in water treatment, manufacturing, and oil and gas production. High-pressure pumps come in many different types, including reciprocating, centrifugal, and positive displacement pumps.

How does a high-pressure pump work?

High-pressure pumps work by using a motor to drive a piston or impeller, which creates a high-pressure flow of fluid. Reciprocating pumps use a piston that moves back and forth to create pressure, while centrifugal pumps use an impeller that spins to create pressure. Positive displacement pumps, on the other hand, use a mechanical device to move fluid through a series of chambers or pockets, which creates pressure.

Applications of high-pressure pumps

High-pressure pumps are used in a wide range of applications, including:

- Water treatment: High-pressure pumps are used to treat water in many different ways, such as reverse osmosis, desalination, and filtration.

- Manufacturing: High-pressure pumps are used in many manufacturing processes, such as in the production of plastics, paper, and textiles.

- Oil and gas production: High-pressure pumps are used in the oil and gas industry to extract and transport crude oil and natural gas.

- Food processing: High-pressure pumps are used in the food processing industry to pasteurize food and beverages.

- Cleaning: High-pressure pumps are used in cleaning applications, such as in pressure washing and steam cleaning.

Benefits of using a high-pressure pump

There are many benefits to using a high-pressure pump, including:

- Increased efficiency: High-pressure pumps can move fluids more efficiently than low-pressure pumps, which can save energy and reduce operating costs.

- Increased productivity: High-pressure pumps can move fluids more quickly than low-pressure pumps, which can increase productivity and reduce downtime.

- Improved accuracy: High-pressure pumps can provide more accurate and precise control over fluid flow, which can improve product quality and reduce waste.

- Improved safety: High-pressure pumps are designed to operate safely at high pressures, which can reduce the risk of accidents and injuries.

Conclusion

High-pressure pumps are essential for many industries, and they play a critical role in moving fluids at high pressures. They come in many different types and are used in a wide range of applications, including water treatment, manufacturing, oil and gas production, food processing, and cleaning. Using a high-pressure pump can provide many benefits, including increased efficiency, productivity, accuracy, and safety.

Types of High-Pressure Pumps:

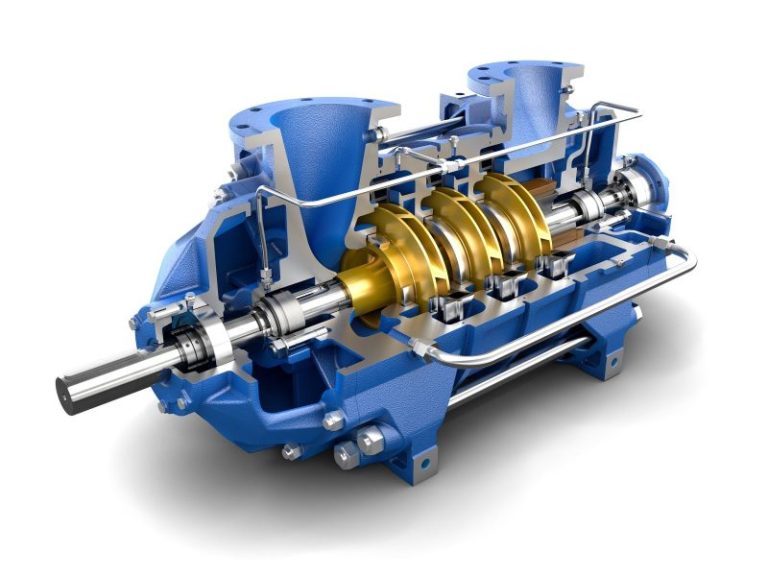

There are three main types of high-pressure pumps: reciprocating pumps, centrifugal pumps, and positive displacement pumps. Each type has its unique features and applications.

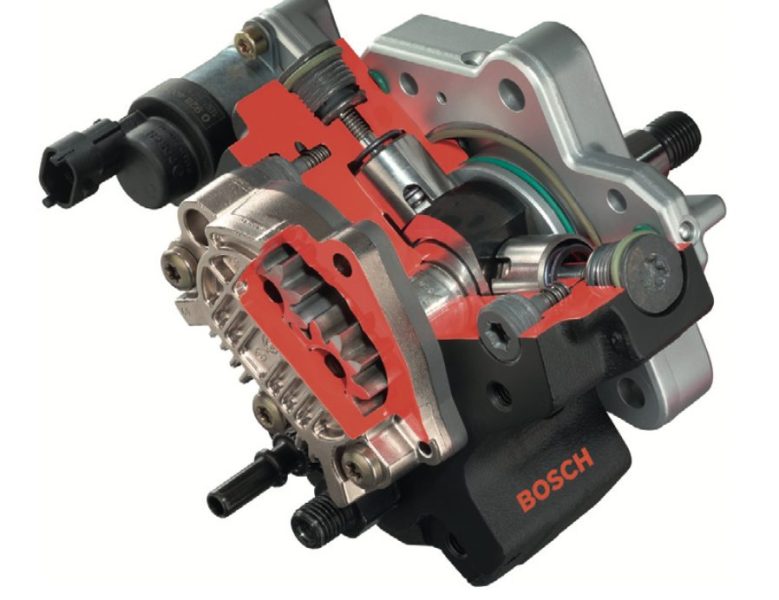

Reciprocating pumps use a piston or plunger to create a pressure difference that forces fluid through the pump. They are ideal for low flow rates and high-pressure applications, such as in oil and gas drilling and water treatment.

Centrifugal pumps use a rotating impeller to create a flow of fluid through the pump. They are ideal for high flow rates and low-pressure applications, such as in irrigation and firefighting.

Positive displacement pumps use a mechanical device to move fluid through a series of chambers or pockets, creating pressure. They are ideal for high-pressure and low flow rate applications, such as in hydraulic systems and pressure washing.

Applications of High-Pressure Pumps:

High-pressure pumps are used in a wide range of applications across many industries, including:

- Oil and gas production: High-pressure pumps are used in drilling, extraction, and transportation of crude oil and natural gas.

- Water treatment: High-pressure pumps are used in reverse osmosis, desalination, and filtration of water.

- Manufacturing: High-pressure pumps are used in the production of plastics, paper, textiles, and other products.

- Food processing: High-pressure pumps are used in pasteurization, homogenization, and sterilization of food and beverages.

- Cleaning: High-pressure pumps are used in pressure washing, steam cleaning, and other cleaning applications.

Benefits of High-Pressure Pumps:

There are many benefits to using high-pressure pumps, including:

- Increased efficiency: High-pressure pumps can move fluids more efficiently than low-pressure pumps, which can save energy and reduce operating costs.

- Increased productivity: High-pressure pumps can move fluids more quickly than low-pressure pumps, which can increase productivity and reduce downtime.

- Improved accuracy: High-pressure pumps can provide more accurate and precise control over fluid flow, which can improve product quality and reduce waste.

- Improved safety: High-pressure pumps are designed to operate safely at high pressures, which can reduce the risk of accidents and injuries.

- Versatility: High-pressure pumps can be used in a wide range of applications and can handle different types of fluids, temperatures, and pressures.

In summary, high-pressure pumps are essential for many industries and play a critical role in moving fluids at high pressures. They come in many different types and are used in a wide range of applications, including oil and gas production, water treatment, manufacturing, food processing, and cleaning. Using a high-pressure pump can provide many benefits, including increased efficiency, productivity, accuracy, and safety.

Advantages of High-Pressure Pumps:

- Increased Efficiency: High-pressure pumps are designed to move fluids more efficiently than low-pressure pumps. This means they use less energy to move the same amount of fluid, which can save on operating costs.

- Improved Productivity: High-pressure pumps can move fluids more quickly than low-pressure pumps. This means they can increase productivity by reducing the time it takes to move fluids from one location to another.

- Precise Control: High-pressure pumps provide more accurate and precise control over fluid flow. This can improve product quality and reduce waste.

- Versatility: High-pressure pumps can be used in a wide range of applications and can handle different types of fluids, temperatures, and pressures.

- Safety: High-pressure pumps are designed to operate safely at high pressures, which can reduce the risk of accidents and injuries.

Disadvantages of High-Pressure Pumps:

- Higher Cost: High-pressure pumps are typically more expensive than low-pressure pumps due to their design and manufacturing process.

- Maintenance: High-pressure pumps require regular maintenance to ensure they continue to operate efficiently and safely. This can add to the overall cost of owning and operating a high-pressure pump.

- Noise: High-pressure pumps can be noisy due to the high speeds and pressures involved in their operation. This can be a problem in residential or other noise-sensitive areas.

- Vibration: High-pressure pumps can create vibration, which can cause damage to nearby structures or equipment if not properly isolated.

- Potential for Injury: High-pressure pumps can be dangerous if not handled properly. They can cause injury or damage if fluid is not properly contained or if the pump is not properly maintained.

In summary, high-pressure pumps offer several advantages, including increased efficiency, improved productivity, precise control, versatility, and safety. However, they also have some disadvantages, such as higher cost, maintenance requirements, noise, vibration, and potential for injury. It is important to consider both the advantages and disadvantages when deciding whether a high-pressure pump is right for your application.