Introduction: The Heated Exhaust Gas Oxygen (HEGO) sensor, also known as the Lambda sensor, is a crucial component in modern-day automotive engines. It measures the oxygen content in the exhaust gases, and sends feedback to the engine control unit (ECU) to adjust the air-fuel ratio, which ensures the engine runs efficiently and cleanly. In this blog, we will discuss the HEGO sensor placed in the inlet manifold and its working principle.

What is a HEGO sensor in the inlet manifold? The HEGO sensor in the inlet manifold is an additional sensor placed in the air intake system, between the air filter and the engine. It measures the oxygen content of the air-fuel mixture before it enters the combustion chamber. The information received from this sensor helps the engine control unit to make necessary adjustments to the air-fuel mixture, which is then injected into the cylinders. The HEGO sensor in the inlet manifold works alongside the exhaust HEGO sensor to ensure the engine operates optimally.

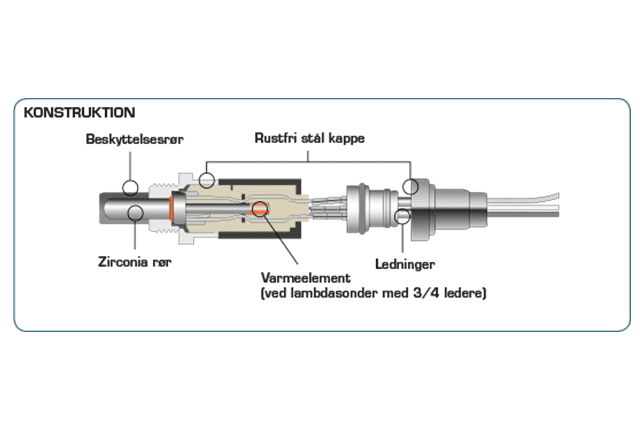

How does it work? The HEGO sensor in the inlet manifold works on the same principle as the exhaust HEGO sensor. It consists of a zirconia element, which is coated with platinum electrodes. When heated to a specific temperature, the zirconia element becomes a conductor of oxygen ions. The sensor generates a voltage signal based on the difference in oxygen content between the reference air outside the sensor and the air-fuel mixture inside the sensor. This voltage signal is sent to the engine control unit, which interprets the signal and adjusts the air-fuel ratio accordingly.

Advantages of HEGO sensor in the inlet manifold: The HEGO sensor in the inlet manifold provides several advantages over traditional systems, such as carburetors or throttle body fuel injection. Here are some of the key advantages of using an HEGO sensor in the inlet manifold:

- Increased fuel efficiency: The HEGO sensor provides feedback to the engine control unit to adjust the air-fuel ratio, which helps to reduce fuel consumption and increase fuel efficiency.

- Reduced emissions: The HEGO sensor ensures the air-fuel mixture is optimized, which leads to lower exhaust emissions and a cleaner exhaust.

- Improved engine performance: The HEGO sensor provides real-time feedback to the engine control unit, which allows it to make necessary adjustments to the air-fuel mixture. This results in improved engine performance and a smoother driving experience.

Conclusion: The Heated Exhaust Gas Oxygen (HEGO) sensor in the inlet manifold is an essential component of modern automotive engines. It provides real-time feedback to the engine control unit to ensure the air-fuel mixture is optimized for maximum efficiency and reduced emissions. The HEGO sensor in the inlet manifold is a crucial addition to the exhaust HEGO sensor, and both work together to ensure the engine operates at peak performance.

Working principle of HEGO sensor in the inlet manifold: The HEGO sensor in the inlet manifold measures the oxygen content of the air-fuel mixture before it enters the combustion chamber. This is important because the air-fuel ratio needs to be precisely controlled to ensure the engine runs efficiently and cleanly.

The sensor contains a zirconia element, which is coated with platinum electrodes. The element is heated to a specific temperature, usually around 300-400°C, to make it a conductor of oxygen ions. When the air-fuel mixture comes into contact with the sensor, the oxygen ions in the mixture diffuse across the zirconia element, generating a voltage signal that is sent to the engine control unit.

The engine control unit interprets the voltage signal and adjusts the air-fuel ratio accordingly. If the voltage signal indicates a high oxygen content, the engine control unit will reduce the amount of fuel injected into the combustion chamber. If the voltage signal indicates a low oxygen content, the engine control unit will increase the amount of fuel injected into the combustion chamber. This feedback loop allows the engine to operate at peak efficiency and with minimal emissions.

Advantages of HEGO sensor in the inlet manifold: The HEGO sensor in the inlet manifold provides several advantages over traditional systems such as carburetors or throttle body fuel injection. Here are some of the key advantages:

- Increased fuel efficiency: The HEGO sensor provides real-time feedback to the engine control unit, allowing it to adjust the air-fuel ratio to the optimal level for maximum fuel efficiency.

- Reduced emissions: The HEGO sensor ensures the air-fuel mixture is optimized, leading to lower exhaust emissions and a cleaner exhaust.

- Improved engine performance: The HEGO sensor allows the engine control unit to make precise adjustments to the air-fuel ratio, resulting in improved engine performance and a smoother driving experience.

- Improved cold start performance: The HEGO sensor in the inlet manifold helps the engine start more quickly and smoothly, even in cold weather conditions, by ensuring the air-fuel ratio is properly adjusted.

Conclusion: The Heated Exhaust Gas Oxygen (HEGO) sensor in the inlet manifold is an essential component of modern automotive engines. It works alongside the exhaust HEGO sensor to provide real-time feedback to the engine control unit, allowing it to adjust the air-fuel ratio for maximum efficiency and reduced emissions. The HEGO sensor in the inlet manifold provides several advantages over traditional systems, including increased fuel efficiency, reduced emissions, improved engine performance, and improved cold start performance.

Advantages:

- Improved fuel efficiency: The HEGO sensor in the inlet manifold provides real-time feedback to the engine control unit, allowing it to adjust the air-fuel ratio to the optimal level for maximum fuel efficiency.

- Reduced emissions: The HEGO sensor ensures the air-fuel mixture is optimized, leading to lower exhaust emissions and a cleaner exhaust.

- Improved engine performance: The HEGO sensor allows the engine control unit to make precise adjustments to the air-fuel ratio, resulting in improved engine performance and a smoother driving experience.

- Improved cold start performance: The HEGO sensor in the inlet manifold helps the engine start more quickly and smoothly, even in cold weather conditions, by ensuring the air-fuel ratio is properly adjusted.

- Long-lasting: HEGO sensors are designed to last for a long time, typically the life of the vehicle.

Disadvantages:

- Costly: HEGO sensors are more expensive than traditional sensors, which can increase the cost of vehicle maintenance and repairs.

- Sensitive to contaminants: HEGO sensors can be sensitive to contaminants in the air, such as dirt and dust, which can cause inaccurate readings and lead to engine problems.

- Failure can cause engine problems: If the HEGO sensor fails, it can cause engine problems such as reduced performance and increased emissions.

- Requires maintenance: HEGO sensors require periodic maintenance, such as cleaning or replacement, to ensure accurate readings and optimal performance.

- Limited functionality: The HEGO sensor only measures the oxygen content in the air-fuel mixture, and cannot provide feedback on other engine parameters such as engine temperature or oil pressure.

Conclusion: The HEGO sensor in the inlet manifold provides several advantages, including improved fuel efficiency, reduced emissions, improved engine performance, improved cold start performance, and long-lasting durability. However, it also has some disadvantages, including higher cost, sensitivity to contaminants, potential failure leading to engine problems, required maintenance, and limited functionality. Despite these drawbacks, the HEGO sensor remains a crucial component in modern automotive engines, providing essential feedback to the engine control unit for optimal engine performance and efficiency.