Flange connections are widely used in various industries, especially in the oil and gas, petrochemical, and power generation industries. They are used to connect piping systems and equipment to ensure safe, efficient, and leak-free operation. In this blog post, we will discuss flange connections, their types, and their applications.

What is a flange connection?

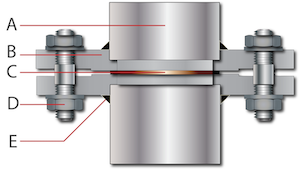

A flange connection is a type of joint that connects two or more pipes or equipment together. It consists of a raised ring or rim (flange) that is attached to the end of a pipe or equipment and is secured by bolts and nuts. The flanges are designed to match each other and can be connected together to create a tight and secure seal.

Types of Flange Connections

There are several types of flange connections, each with its unique design and application. Below are some of the most common types:

- Weld Neck Flange

Weld neck flanges are the most commonly used type of flange connection. They have a long tapered neck that is welded to the pipe or equipment. The weld neck flange provides excellent strength and support, making it suitable for high-pressure and high-temperature applications.

- Slip-On Flange

Slip-on flanges are easy to install and remove. They have a flat face and are slid onto the pipe or equipment and then welded in place. Slip-on flanges are not recommended for high-pressure or high-temperature applications.

- Socket Weld Flange

Socket weld flanges have a socket in which the pipe or equipment is inserted and then welded in place. The socket weld flange provides good strength and support, making it suitable for high-pressure and high-temperature applications.

- Blind Flange

Blind flanges are used to close off the end of a pipe or equipment. They have no opening and are used to prevent the flow of fluid or gas. Blind flanges are also used for maintenance and inspection purposes.

Applications of Flange Connections

Flange connections are used in various industries and applications. Some of the most common applications include:

- Oil and Gas Industry

Flange connections are widely used in the oil and gas industry for connecting pipelines and equipment. They are used for both onshore and offshore applications and can withstand high pressures and temperatures.

- Petrochemical Industry

The petrochemical industry uses flange connections to connect processing equipment and piping systems. Flange connections are used to transport hazardous and corrosive fluids and gases, making it important to have a tight and secure seal.

- Power Generation Industry

Flange connections are used in the power generation industry to connect steam and gas turbines, boilers, and heat exchangers. These applications require a secure and tight seal to prevent leakage and ensure efficient operation.

Conclusion

In conclusion, flange connections are an essential component in various industries, ensuring safe and efficient operation of piping systems and equipment. There are several types of flange connections, each with its unique design and application. It’s important to choose the right type of flange connection for the application to ensure a secure and tight seal.

Flange connections are critical components in many industries, including oil and gas, petrochemical, power generation, and more. They are used to connect pipelines, equipment, and other components together, ensuring a tight and secure seal that prevents leaks, reduces the risk of accidents, and ensures efficient operation.

The different types of flange connections vary in their design and application. For example, weld neck flanges have a long tapered neck that is welded to the pipe or equipment, providing excellent strength and support that is ideal for high-pressure and high-temperature applications. On the other hand, slip-on flanges are easy to install and remove but are not recommended for high-pressure or high-temperature applications.

Socket weld flanges have a socket in which the pipe or equipment is inserted and then welded in place, providing good strength and support. Blind flanges, as their name suggests, are used to close off the end of a pipe or equipment and are often used for maintenance and inspection purposes.

Flange connections are used in many different applications across various industries. For example, in the oil and gas industry, flange connections are used to connect pipelines, offshore platforms, and other equipment, and must be able to withstand high pressures and temperatures. In the petrochemical industry, flange connections are used to transport hazardous and corrosive fluids and gases, making a tight and secure seal essential for safety reasons.

In the power generation industry, flange connections are used to connect steam and gas turbines, boilers, and heat exchangers, and must be able to withstand high temperatures and pressures to ensure efficient operation. Flange connections are also used in other industries, such as water treatment, food and beverage production, and pharmaceuticals, among others.

In summary, flange connections are critical components in many industries, and choosing the right type of flange connection is essential to ensure safe and efficient operation. Different types of flange connections have unique designs and applications, and understanding their characteristics is crucial to selecting the right one for a specific application.

Advantages of Flange Connections:

- Secure and leak-proof: Flange connections provide a tight and secure seal that prevents leaks, reducing the risk of accidents, and ensuring safe operation.

- Versatile: Flange connections are widely used in various industries, from oil and gas to power generation, and can be used to connect different types of equipment and piping systems.

- Easy to assemble and disassemble: Flange connections can be easily assembled and disassembled, making them ideal for applications that require regular maintenance or modification.

- High strength: Some types of flange connections, such as weld neck flanges, are designed to provide excellent strength and support, making them suitable for high-pressure and high-temperature applications.

Disadvantages of Flange Connections:

- Cost: Flange connections can be more expensive than other types of connections, such as threaded connections, particularly if special flanges are required.

- Require skilled labor: Flange connections require skilled labor to install correctly and ensure a tight and secure seal. If not installed correctly, they can cause leaks and other problems.

- Size limitations: Flange connections can be bulky and require more space than other types of connections, making them unsuitable for some applications where space is limited.

- Vulnerable to corrosion: Flange connections can be vulnerable to corrosion, particularly if they are not made from the right materials or are exposed to corrosive environments. Regular inspection and maintenance are essential to prevent corrosion-related problems.

In summary, flange connections provide many advantages, such as being secure, versatile, and easy to assemble and disassemble. However, they also have some disadvantages, including their cost, the need for skilled labor, size limitations, and vulnerability to corrosion. Choosing the right type of flange connection for a specific application and ensuring proper installation and maintenance can help overcome these disadvantages and ensure safe and efficient operation.