A camshaft position sensor, also known as a CMP sensor, is a crucial component in a modern automotive engine’s operation. This sensor is responsible for providing critical data to the engine control module (ECM) regarding the position of the camshaft(s) in relation to the engine’s crankshaft. In this blog, we’ll dive deeper into the importance of camshaft position sensors, how they work, and their maintenance requirements.

What is a Camshaft Position Sensor? A camshaft position sensor is a small electronic device that monitors the rotational position of the camshaft(s) in an engine. It typically works in conjunction with a crankshaft position sensor to provide real-time data to the ECM. The ECM uses this data to adjust the engine’s timing, fuel injection, and other critical parameters to ensure smooth operation.

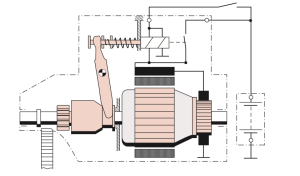

How Does a Camshaft Position Sensor Work? Camshaft position sensors use one of two primary sensing methods: a Hall Effect sensor or a magnetoresistive (MR) sensor. Both methods rely on the presence of a rotating camshaft to generate a signal that the sensor can detect.

In a Hall Effect sensor, a magnetic field is used to detect the presence and movement of a ferromagnetic object (in this case, a camshaft). As the camshaft rotates, it generates a magnetic field that the Hall Effect sensor can detect. The sensor then sends a signal to the ECM, indicating the camshaft’s position.

In an MR sensor, a small strip of ferromagnetic material is used to detect changes in magnetic fields. As the camshaft rotates, the magnetic field around it changes, which the MR sensor can detect. This change in magnetic field generates an electrical signal that the sensor sends to the ECM.

Both types of camshaft position sensors work in a similar way, using the presence and movement of a rotating camshaft to generate an electrical signal that the ECM can use to adjust engine operation.

Why is a Camshaft Position Sensor Important? A camshaft position sensor is critical to an engine’s operation, as it provides the ECM with essential data regarding the camshaft’s position. This data is used to adjust the engine’s timing, fuel injection, and other parameters, ensuring smooth and efficient operation. Without a working camshaft position sensor, an engine may not run at all, or it may run poorly, with reduced power and fuel efficiency.

Common Symptoms of a Failing Camshaft Position Sensor Like any automotive component, camshaft position sensors can fail over time. Common symptoms of a failing camshaft position sensor include:

- Difficulty Starting: If the engine is difficult to start or won’t start at all, a faulty camshaft position sensor may be to blame.

- Poor Performance: A failing camshaft position sensor can cause the engine to run poorly, with reduced power and fuel efficiency.

- Stalling: If the engine stalls frequently or unexpectedly, a faulty camshaft position sensor may be the cause.

- Check Engine Light: A faulty camshaft position sensor can trigger the check engine light to come on, indicating a problem with the engine.

Maintenance Requirements for Camshaft Position Sensors Fortunately, camshaft position sensors are relatively low-maintenance components. They typically require no regular maintenance, although they can fail over time due to wear and tear. If you experience any of the symptoms listed above, it’s essential to have your vehicle inspected by a qualified mechanic who can diagnose and repair any issues with your camshaft position sensor.

Conclusion A camshaft position sensor is a crucial component in any modern automotive engine. It provides essential data to the ECM, which uses it to adjust engine timing, fuel injection, and other parameters to ensure smooth and efficient operation. If you experience any symptoms of a failing camshaft position sensor, it’s essential to have your vehicle inspected by a qualified mechanic

Types of Camshaft Position Sensors There are two main types of camshaft position sensors: magnetic sensors and Hall Effect sensors. Magnetic sensors use a permanent magnet to generate a magnetic field around the sensor. As the camshaft rotates, it causes changes in the magnetic field, which are detected by the sensor. Hall Effect sensors use a Hall Effect semiconductor to detect changes in magnetic fields. They operate in a similar way to magnetic sensors but are generally more precise and have a wider range of operating temperatures.

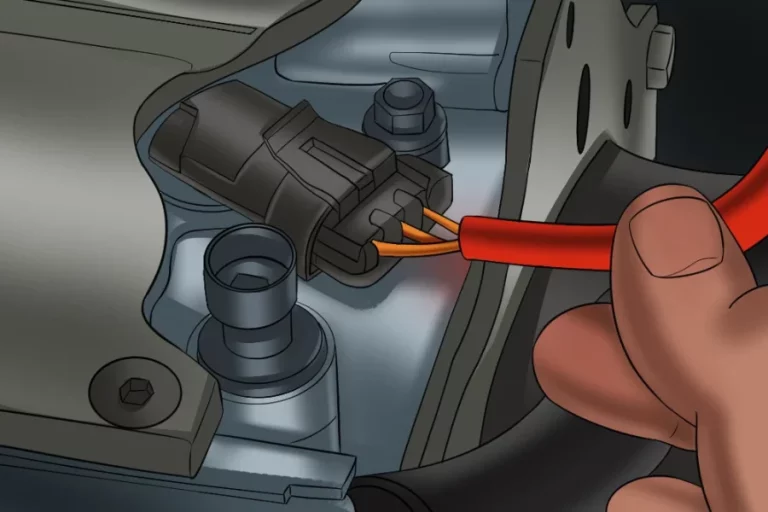

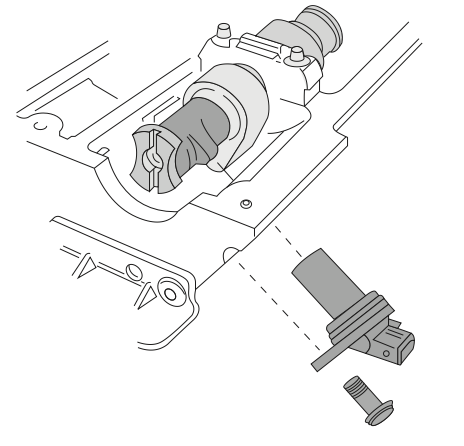

Location of Camshaft Position Sensors The location of the camshaft position sensor(s) varies depending on the engine design. In some engines, the sensor(s) are mounted on the camshaft cover or cylinder head, while in others, they are mounted directly on the camshaft(s). In some cases, there may be multiple camshaft position sensors, depending on the engine design and number of camshafts.

Importance of Camshaft Timing Camshaft timing is critical to an engine’s performance and efficiency. The camshaft(s) control the opening and closing of the engine’s valves, which allows air and fuel to enter the combustion chamber and exhaust gases to exit. If the camshaft timing is off, it can result in poor engine performance, reduced fuel efficiency, and increased emissions.

Camshaft position sensors play a crucial role in ensuring that the camshaft timing is correct. They provide real-time data to the ECM, which can adjust the engine’s timing as needed to ensure smooth operation.

Troubleshooting Camshaft Position Sensor Issues If you experience any symptoms of a failing camshaft position sensor, it’s important to have your vehicle inspected by a qualified mechanic. They can use specialized diagnostic equipment to test the sensor and determine whether it needs to be repaired or replaced.

In some cases, the issue may be a wiring problem or a faulty ECM, rather than a faulty sensor. A qualified mechanic can help identify and diagnose the root cause of the problem.

In conclusion, camshaft position sensors are critical components in modern automotive engines. They play a crucial role in ensuring smooth engine operation, fuel efficiency, and emissions control. If you experience any symptoms of a failing camshaft position sensor, it’s important to have your vehicle inspected by a qualified mechanic to ensure that the issue is resolved promptly and effectively.

Advantages:

- Improved engine performance: Camshaft position sensors help to ensure that the engine is timed correctly, which results in improved engine performance and efficiency.

- Increased fuel efficiency: By ensuring that the engine is timed correctly, camshaft position sensors can help to increase fuel efficiency and reduce emissions.

- Improved diagnostic capability: The use of camshaft position sensors has improved the diagnostic capabilities of modern engines. The sensors provide real-time data to the ECM, which can be used to quickly diagnose and resolve engine issues.

- Cost-effective: Camshaft position sensors are relatively inexpensive components, and their use can help to prevent more expensive engine repairs down the line.

Disadvantages:

- Potential for failure: Like any mechanical or electrical component, camshaft position sensors can fail over time, which can result in engine performance issues and potentially expensive repairs.

- Limited lifespan: Camshaft position sensors have a limited lifespan and will eventually need to be replaced.

- Difficulty of replacement: In some engine designs, replacing the camshaft position sensor can be a difficult and time-consuming process.

- Compatibility issues: Camshaft position sensors must be compatible with the specific make and model of the vehicle, which can limit options for replacement parts.

In conclusion, while camshaft position sensors offer numerous advantages in terms of improved engine performance, fuel efficiency, and diagnostic capabilities, they also have some potential drawbacks, including the potential for failure, limited lifespan, difficulty of replacement, and compatibility issues. However, the benefits of camshaft position sensors generally outweigh the disadvantages, and they remain an important component in modern automotive engines.