The Bosch DI-Motronic is an engine management system used in gasoline-powered vehicles that was first introduced in the mid-1980s. It is an acronym for Direct Injection Motronic, and it uses a combination of electronic fuel injection and ignition control to optimize the performance and fuel efficiency of the engine.

The DI-Motronic system is capable of monitoring and adjusting several key engine parameters, including air intake, fuel injection, and ignition timing. By continuously analyzing these factors, the system can make real-time adjustments to optimize engine performance and minimize fuel consumption.

One of the key features of the DI-Motronic system is its use of direct fuel injection. Unlike traditional fuel injection systems, which introduce fuel into the intake manifold, the DI-Motronic system injects fuel directly into the combustion chamber. This provides a more precise and efficient fuel delivery system, which results in better engine performance and fuel efficiency.

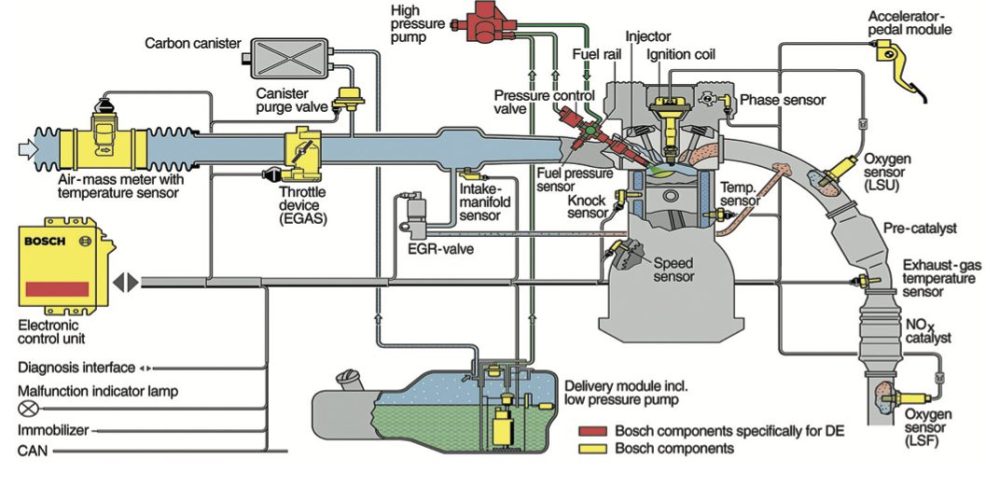

Another important feature of the DI-Motronic system is its use of an electronic control unit (ECU). The ECU is responsible for monitoring and adjusting engine parameters, based on data collected from various sensors located throughout the engine. The ECU can also communicate with other vehicle systems, such as the transmission and emissions control system, to ensure optimal performance and compliance with emissions regulations.

The DI-Motronic system has evolved over the years, with newer versions incorporating more advanced features such as variable valve timing, turbocharging, and hybrid technology. Today, the DI-Motronic system is used in a wide range of gasoline-powered vehicles, from small cars to high-performance sports cars.

Overall, the Bosch DI-Motronic system has proven to be a reliable and effective engine management system, capable of optimizing engine performance and fuel efficiency. As automotive technology continues to evolve, it is likely that we will see further advancements in the DI-Motronic system and other engine management technologies.

The DI-Motronic system operates based on data collected by various sensors located throughout the engine, such as the throttle position sensor, oxygen sensor, and manifold absolute pressure sensor. The system uses this data to determine the optimal air/fuel ratio and ignition timing for the engine.

The system’s direct fuel injection technology provides several advantages over traditional fuel injection systems. By injecting fuel directly into the combustion chamber, the DI-Motronic system can precisely control the amount of fuel delivered to the engine. This results in better fuel efficiency, improved engine performance, and reduced emissions.

The DI-Motronic system also uses an electronic control unit (ECU) to manage engine performance. The ECU collects data from the various sensors located throughout the engine and uses this data to control the fuel injection, ignition timing, and other engine functions. The ECU can adjust these parameters in real-time, allowing the engine to operate more efficiently and effectively under a variety of driving conditions.

The DI-Motronic system is also capable of detecting engine faults and malfunctions. If a problem is detected, the system will trigger a warning light on the vehicle’s dashboard and may even enter into a “limp mode” to protect the engine from further damage.

The DI-Motronic system has evolved over the years, with newer versions incorporating more advanced features such as variable valve timing, turbocharging, and hybrid technology. These advancements have further improved engine performance and fuel efficiency, while also reducing emissions.

In summary, the Bosch DI-Motronic system is a sophisticated engine management system that uses direct fuel injection, an electronic control unit, and advanced sensors to optimize engine performance and fuel efficiency. Its advanced technology has helped to make gasoline-powered vehicles more efficient, reliable, and environmentally friendly.

Advantages:

- Improved Fuel Efficiency: The direct fuel injection technology used by the DI-Motronic system provides precise control over the amount of fuel delivered to the engine. This results in better fuel efficiency and reduced emissions.

- Improved Engine Performance: The DI-Motronic system’s electronic control unit can adjust engine parameters in real-time, allowing for optimal engine performance under a variety of driving conditions. This can result in better acceleration, smoother operation, and overall improved performance.

- Reduced Emissions: By controlling fuel delivery and ignition timing more precisely, the DI-Motronic system can reduce harmful emissions such as carbon monoxide and nitrogen oxides.

- Better Reliability: The DI-Motronic system uses advanced sensors to monitor engine performance and detect faults or malfunctions. This helps to prevent costly repairs and prolong the life of the engine.

Disadvantages:

- Higher Cost: The advanced technology used by the DI-Motronic system can increase the cost of the vehicle. This may make it less affordable for some consumers.

- Complexity: The DI-Motronic system is a sophisticated engine management system that requires advanced technology and specialized knowledge to repair and maintain. This can make repairs and maintenance more costly and time-consuming.

- Dependence on Sensors: The DI-Motronic system relies heavily on data collected by various sensors located throughout the engine. If one or more of these sensors fail, it can cause problems with the engine’s performance.

- Maintenance Requirements: Like any complex system, the DI-Motronic system requires regular maintenance to ensure proper operation. This can include sensor replacements, software updates, and other maintenance tasks.

In summary, while the Bosch DI-Motronic system offers many benefits, including improved fuel efficiency, better engine performance, and reduced emissions, it also has some drawbacks, including higher cost, complexity, and maintenance requirements. However, overall, the benefits of this system have made it a popular choice for many gasoline-powered vehicles.