Noise pollution is a significant problem in our society, and it has a considerable impact on our daily lives. Industrial machinery, transportation, and construction sites are some of the sources of excessive noise levels. Therefore, there is a need for a solution to reduce the noise levels generated by these sources. One of the most commonly used solutions is the baffle silencer. In this blog post, we will discuss what a baffle silencer is, how it works, and its various applications.

What is a Baffle Silencer?

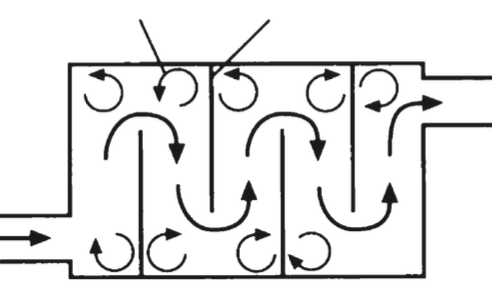

A baffle silencer is a type of noise reduction device that is used to reduce the noise levels generated by various sources. It consists of a series of baffles or plates that are designed to reflect and absorb sound waves. These plates are arranged in a specific pattern and are placed inside a pipe or duct, which is connected to the noise source. The sound waves enter the baffle silencer through the pipe and are directed towards the baffles. The baffles reflect the sound waves, which bounce back and forth between the plates, and the sound waves are eventually absorbed by the material of the plates. As a result, the noise levels are significantly reduced.

How does a Baffle Silencer work?

A baffle silencer works on the principle of sound attenuation. When sound waves enter the baffle silencer, they are directed towards the baffles or plates, which are made of sound-absorbing materials. The sound waves bounce back and forth between the baffles, and as they travel through the plates, they lose their energy due to the friction with the material of the plates. This process is known as sound attenuation, and it reduces the amplitude and frequency of the sound waves.

The design of the baffle silencer is critical to its effectiveness. The distance between the plates, the size and shape of the plates, and the material used for the plates are all factors that affect the performance of the baffle silencer. The length of the baffle silencer also plays a significant role in its effectiveness. Longer baffle silencers tend to be more effective in reducing noise levels.

Applications of Baffle Silencers:

Baffle silencers are widely used in various industries, including:

- HVAC systems – Baffle silencers are commonly used in heating, ventilation, and air conditioning systems to reduce the noise levels generated by the air handlers and ductwork.

- Power generation – Baffle silencers are used in power generation facilities to reduce the noise levels generated by the turbines, generators, and other equipment.

- Industrial machinery – Baffle silencers are used in various types of industrial machinery, including compressors, pumps, and engines, to reduce the noise levels generated by these machines.

- Transportation – Baffle silencers are used in vehicles and transportation systems, including trains, airplanes, and ships, to reduce the noise levels generated by the engines and other equipment.

Conclusion:

In conclusion, a baffle silencer is an effective noise reduction device that is widely used in various industries to reduce the noise levels generated by various sources. Its design and the materials used play a significant role in its effectiveness, and it is essential to choose the right type of baffle silencer for a particular application. With the growing concern for noise pollution, baffle silencers are becoming increasingly popular and will continue to play a vital role in reducing noise levels in our society.

Design Considerations:

The design of a baffle silencer can significantly impact its effectiveness in reducing noise levels. One important factor to consider is the distance between the plates or baffles. The closer the plates are to each other, the more effective the baffle silencer will be in reducing noise levels. However, a closer spacing can also increase the pressure drop across the baffle silencer, which can reduce the efficiency of the system. Therefore, the distance between the plates should be optimized based on the specific application.

Another important design consideration is the size and shape of the plates. The plates should be large enough to reflect and absorb sound waves effectively. The shape of the plates can also impact the performance of the baffle silencer. For example, using curved plates can improve the acoustic performance of the baffle silencer by increasing the amount of surface area available for sound absorption.

The material used to construct the baffle silencer can also impact its effectiveness. Common materials used include fiberglass, foam, and metal. Fiberglass is a popular choice due to its high sound absorption properties, low cost, and ease of installation. Foam materials are also commonly used for their sound absorption properties and lightweight nature. Metal baffles can provide a high degree of sound reflection and can be more durable than other materials.

Applications:

Baffle silencers are used in a wide range of applications across many different industries. In HVAC systems, baffle silencers can be used to reduce noise levels generated by air handlers, ductwork, and HVAC equipment such as fans and compressors. In the power generation industry, baffle silencers are commonly used to reduce noise levels generated by turbines, generators, and other equipment. In industrial settings, baffle silencers can be used to reduce noise levels generated by machinery such as compressors, pumps, and engines. Baffle silencers can also be used in transportation applications, such as reducing noise levels generated by engines and other equipment in trains, airplanes, and ships.

Benefits:

The primary benefit of using a baffle silencer is the reduction in noise levels, which can improve working conditions for employees and reduce noise pollution in the surrounding environment. Additionally, using baffle silencers can improve equipment performance by reducing pressure drops and increasing energy efficiency. Baffle silencers can also improve safety by reducing noise-induced hearing loss and other health issues associated with exposure to excessive noise levels.

In conclusion, baffle silencers are a versatile and effective solution for reducing noise levels across many different industries and applications. Their design and material selection are critical to their performance, and choosing the right type of baffle silencer for a specific application is essential. With the growing awareness of the negative impacts of noise pollution, baffle silencers will continue to play a vital role in improving working conditions and reducing noise levels in our society.

Advantages:

- Effective Noise Reduction: Baffle silencers are effective at reducing noise levels across a wide range of frequencies. They work by reflecting and absorbing sound waves, which reduces the amount of noise that reaches the surrounding environment.

- Versatility: Baffle silencers can be used in a wide range of applications across many different industries. They can be used to reduce noise levels generated by HVAC equipment, industrial machinery, power generation equipment, and transportation vehicles.

- Energy Efficiency: Baffle silencers can improve energy efficiency by reducing pressure drops and improving airflow through equipment. This can lead to lower energy costs and improved equipment performance.

- Durability: Baffle silencers are typically constructed using durable materials such as metal, fiberglass, or foam. This means they can withstand harsh environments and have a longer lifespan than other types of noise reduction solutions.

Disadvantages:

- Space Limitations: Baffle silencers require a significant amount of space to be effective. This can be a challenge in applications where space is limited, such as in urban areas or on transportation vehicles.

- Pressure Drop: Baffle silencers can cause a pressure drop across the system, which can reduce the efficiency of equipment such as HVAC systems, compressors, and turbines. This can lead to higher energy costs and reduced equipment performance.

- Maintenance: Baffle silencers require regular maintenance to ensure they continue to function effectively. This can include cleaning, replacing damaged plates or baffles, and checking for leaks.

- Cost: Baffle silencers can be more expensive than other types of noise reduction solutions. The cost can vary depending on the size, material, and design of the baffle silencer.

In conclusion, while baffle silencers have some disadvantages such as space limitations and pressure drop, their advantages such as effective noise reduction, versatility, energy efficiency, and durability make them a popular choice for reducing noise levels across many different industries and applications.