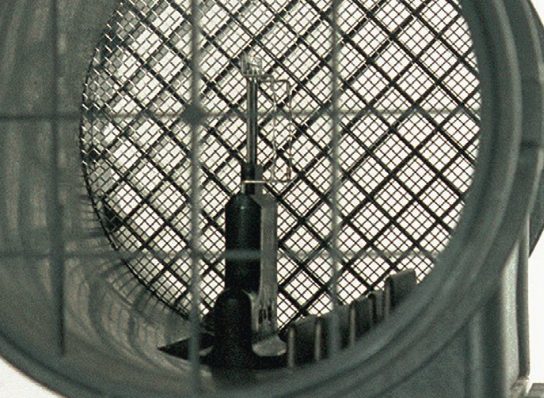

An air flow meter, also known as an air flow sensor or mass air flow sensor, is a device used to measure the amount of air flowing into an internal combustion engine. It plays a crucial role in the engine’s fuel injection system by providing accurate information about the amount of air entering the engine, which allows the engine control module to adjust the fuel delivery accordingly.

There are several types of air flow meters available on the market, but the most common types are hot wire air flow meters, vane air flow meters, and Karman vortex air flow meters.

Hot wire air flow meters work by passing a current through a thin wire, which heats up as the air flows past it. The temperature of the wire changes as the air flows past it, and the change in temperature is used to calculate the air flow rate.

Vane air flow meters, also known as mechanical air flow meters, use a spring-loaded vane that is deflected by the airflow. The amount of deflection is proportional to the air flow rate and is used to calculate the air flow rate.

Karman vortex air flow meters work by measuring the frequency of vortices that are created when air flows past a bluff body in the meter. The frequency of the vortices is proportional to the air flow rate and is used to calculate the air flow rate.

Air flow meters are typically located between the air filter and the throttle body, and they are connected to the engine control module through a wiring harness. The engine control module uses the air flow meter’s signal to adjust the fuel delivery, which ensures that the engine operates efficiently and meets emissions regulations.

If the air flow meter fails or malfunctions, it can cause a variety of problems with the engine’s performance, such as poor fuel economy, reduced power output, and increased emissions. Some common symptoms of a failing air flow meter include rough idle, stalling, hesitation, and a check engine light.

In conclusion, air flow meters are an essential component of an internal combustion engine’s fuel injection system. They provide accurate information about the amount of air entering the engine, which allows the engine control module to adjust the fuel delivery accordingly. If you suspect that your air flow meter is failing, it’s important to have it diagnosed and repaired as soon as possible to ensure that your engine operates efficiently and reliably.

Air flow meters are crucial for the operation of modern engines, especially those with fuel injection systems. The amount of air entering the engine needs to be carefully measured and controlled to ensure that the correct amount of fuel is injected, which in turn affects the engine’s performance, fuel efficiency, and emissions.

When the engine is running, air flows into the air filter, through the air flow meter, and into the throttle body. The air flow meter measures the amount of air flowing past it and sends a signal to the engine control module, which uses the information to adjust the fuel injection timing and amount.

If the air flow meter is faulty or not calibrated correctly, it can cause the engine to run too rich or too lean, which can result in a variety of problems. For example, running too rich can cause excessive fuel consumption, reduced power output, and increased emissions. Running too lean can cause misfires, overheating, and engine damage.

There are several factors that can affect the accuracy of air flow meters, including air density, temperature, and pressure. Manufacturers design air flow meters to be accurate across a range of operating conditions, but some types of air flow meters are more sensitive to changes in these factors than others.

For example, hot wire air flow meters are more sensitive to temperature changes than vane or Karman vortex air flow meters. They can also be affected by buildup of dirt or oil on the hot wire, which can reduce their accuracy. On the other hand, vane air flow meters can be affected by changes in air density or pressure, which can cause them to under-report the amount of air flowing into the engine.

In addition to mechanical wear and tear, air flow meters can also be affected by electrical faults, such as broken wires or faulty sensors. This can cause the engine control module to receive incorrect signals, which can lead to incorrect fuel injection and engine performance.

In summary, air flow meters are essential components of modern engine fuel injection systems. They provide accurate information about the amount of air flowing into the engine, which is used to control the fuel injection timing and amount. If an air flow meter is faulty or not calibrated correctly, it can cause a variety of problems with the engine’s performance, fuel efficiency, and emissions. It’s important to have your air flow meter diagnosed and repaired by a qualified mechanic if you suspect it is not functioning properly.

Advantages of Air Flow Meters:

- Accurate measurement: Air flow meters provide accurate measurement of the amount of air entering the engine, which is crucial for the fuel injection system to operate properly.

- Better fuel efficiency: By providing accurate information about the amount of air entering the engine, air flow meters allow the engine control module to adjust the fuel delivery accordingly, which can result in better fuel efficiency.

- Improved emissions: By ensuring that the engine is running at the correct air-to-fuel ratio, air flow meters can help to reduce emissions, which is important for meeting environmental regulations.

- Easy to install: Air flow meters are typically easy to install and can be replaced without requiring any special tools or equipment.

Disadvantages of Air Flow Meters:

- Sensitive to operating conditions: Air flow meters can be sensitive to changes in air density, temperature, and pressure, which can affect their accuracy. Some types of air flow meters are more sensitive to these factors than others.

- Prone to failure: Air flow meters can be prone to failure due to mechanical wear and tear or electrical faults. When they fail, they can cause a variety of problems with the engine’s performance, fuel efficiency, and emissions.

- Costly to replace: Air flow meters can be expensive to replace, especially if they are a proprietary part that can only be purchased from the original equipment manufacturer.

- Limited lifespan: Air flow meters have a limited lifespan, typically between 100,000 and 150,000 miles, depending on the make and model of the vehicle. After this point, they may become less accurate or fail completely, which can lead to engine problems.