Turbocharging and exhaust gas recirculation (EGR) are two commonly used technologies in modern engine design to improve performance and reduce emissions. These systems work together to increase power output while also reducing harmful emissions. In this blog, we will take a closer look at the air and exhaust flow in a turbocharged system with EGR and how these systems work together to optimize engine performance.

Turbocharging is a technology that uses a turbine-driven compressor to force more air into the engine, which in turn increases the power output. When an engine is turbocharged, the exhaust gases from the engine spin a turbine, which then drives a compressor. The compressor pressurizes the air, allowing more of it to enter the engine’s combustion chamber, resulting in a more powerful explosion.

Exhaust gas recirculation (EGR) is a technology that reduces emissions by recirculating some of the engine’s exhaust gas back into the engine’s combustion chamber. This helps to lower the combustion temperature and reduce the formation of harmful nitrogen oxides (NOx). The EGR system works by diverting some of the exhaust gases back into the intake manifold, where they mix with fresh air before entering the combustion chamber.

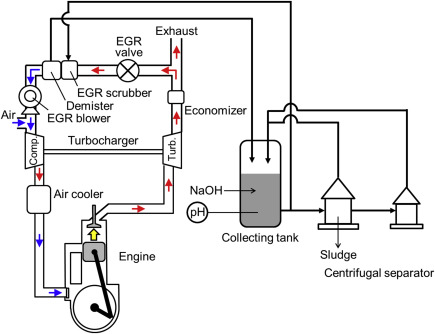

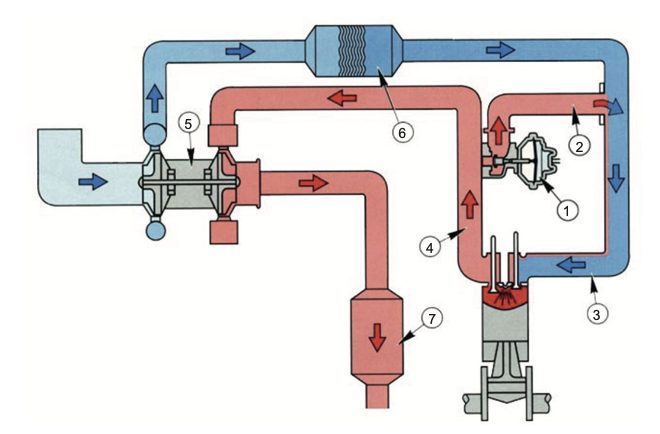

In a turbocharged system with EGR, the air and exhaust flow is carefully managed to optimize performance and reduce emissions. The turbocharger compresses the incoming air, which is then cooled by an intercooler before entering the engine’s combustion chamber. The EGR system recirculates some of the exhaust gases back into the intake manifold, where they mix with fresh air before entering the combustion chamber.

The turbocharger and EGR system work together to optimize engine performance. The turbocharger increases the amount of air entering the engine, which increases the power output. However, this also increases the combustion temperature, which can lead to the formation of harmful NOx emissions. The EGR system helps to reduce these emissions by lowering the combustion temperature.

The air and exhaust flow in a turbocharged system with EGR is carefully managed to ensure that the engine operates efficiently and produces minimal emissions. The turbocharger and EGR system work together to increase power output while reducing harmful emissions, making these technologies an essential part of modern engine design. As engine technology continues to evolve, we can expect to see further improvements in turbocharging and EGR systems, leading to even more efficient and environmentally friendly engines.

Let’s dive deeper into the air and exhaust flow in a turbocharged system with EGR.

As mentioned earlier, the turbocharger compresses the incoming air, which increases the power output of the engine. However, compressing the air also heats it up, which can reduce its density and oxygen content. To counteract this, a charge air cooler, also known as an intercooler, is used to cool down the compressed air before it enters the engine’s combustion chamber. This helps to increase the density and oxygen content of the air, which in turn leads to more complete combustion and better performance.

The EGR system recirculates some of the exhaust gases back into the intake manifold, where they mix with fresh air before entering the combustion chamber. This reduces the amount of oxygen available for combustion and lowers the combustion temperature, which reduces the formation of harmful NOx emissions. The amount of exhaust gas recirculated is carefully controlled by the engine’s electronic control module (ECM) to optimize performance and reduce emissions.

The air and exhaust flow in a turbocharged system with EGR is also affected by the engine’s throttle. When the throttle is closed, the turbocharger is still spinning, which can create a build-up of pressure in the intake system. To prevent this, a blow-off valve or diverter valve is used to release the excess pressure. When the throttle is opened, the turbocharger spins faster and increases the amount of air entering the engine.

Another factor that affects the air and exhaust flow in a turbocharged system with EGR is the engine’s exhaust system. The exhaust gases are expelled from the engine and travel through the exhaust manifold, turbocharger, and finally the exhaust system. The turbocharger uses the energy from the exhaust gases to spin its turbine, which in turn drives the compressor. The exhaust system is also designed to reduce noise and emissions, typically using a muffler and catalytic converter.

In summary, the air and exhaust flow in a turbocharged system with EGR is a complex and carefully controlled process.