When it comes to reducing noise levels in industrial environments, one common solution is to use an absorption silencer. An absorption silencer is a device designed to reduce the sound level of exhaust gases and other noise sources by using sound-absorbing materials. In this blog, we’ll take a closer look at what absorption silencers are, how they work, and their various applications.

What is an absorption silencer?

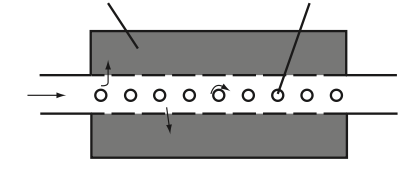

An absorption silencer is a device used to reduce the noise level of exhaust gases, ventilation systems, and other noise sources. The device is made up of two main parts: an outer shell, which is typically made of steel, and an inner lining, which is filled with sound-absorbing materials. The sound-absorbing materials are designed to absorb sound waves and convert them into heat energy, which is then dissipated into the surrounding environment.

How does an absorption silencer work?

An absorption silencer works by reducing the amount of sound energy that is reflected back into the environment. When sound waves encounter the sound-absorbing material inside the silencer, they are absorbed and converted into heat energy. This reduces the overall sound energy that is reflected back into the environment, effectively reducing the noise level.

The sound-absorbing materials used in absorption silencers are typically made from materials like fiberglass or mineral wool. These materials are highly porous and are designed to trap sound waves inside their fibers, where they are then absorbed and dissipated as heat energy.

Applications of absorption silencers

Absorption silencers are commonly used in a variety of industrial applications, including power generation, HVAC systems, and manufacturing processes. In power generation, absorption silencers are used to reduce the noise level of exhaust gases from diesel generators and other types of power plants. In HVAC systems, absorption silencers are used to reduce the noise level of air handlers and other types of ventilation equipment. In manufacturing processes, absorption silencers are used to reduce the noise level of machinery and other types of equipment.

Benefits of absorption silencers

The primary benefit of absorption silencers is their ability to reduce the noise level of industrial environments. This can help to improve worker safety and productivity, as well as reduce the overall impact of industrial noise on the surrounding community. Additionally, absorption silencers are relatively simple to install and maintain, and they can be customized to meet the specific needs of each application.

In conclusion, absorption silencers are a highly effective solution for reducing noise levels in industrial environments. By using sound-absorbing materials to trap and dissipate sound waves, these devices can help to improve worker safety and productivity while reducing the overall impact of industrial noise on the surrounding community. If you’re in need of a solution for reducing noise levels in your industrial facility, an absorption silencer may be just what you need.

Sure! Let’s dive a bit deeper into the topic of absorption silencers.

Types of absorption silencers

There are several different types of absorption silencers, each with its own unique design and application. One common type is the reactive absorption silencer, which uses a combination of sound-absorbing materials and resonant chambers to reduce noise levels. Another type is the dissipative absorption silencer, which uses a dense, fibrous material to absorb sound waves and convert them into heat energy.

Additionally, there are two main categories of absorption silencers: inlet silencers and outlet silencers. Inlet silencers are designed to reduce the noise level of incoming air or gas, while outlet silencers are designed to reduce the noise level of exhaust gases.

- Factors to consider when selecting an absorption silencer

When selecting an absorption silencer for a specific application, there are several factors that must be considered. These include:

- The specific noise source: Different noise sources produce different types of sound waves, which may require different types of silencers to effectively reduce the noise level.

- The flow rate: The flow rate of the gas or air passing through the silencer will affect its performance. It’s important to select a silencer that is properly sized for the specific flow rate of the application.

- The operating conditions: The temperature and pressure of the gas or air passing through the silencer will affect its performance and durability. It’s important to select a silencer that is designed to withstand the specific operating conditions of the application.

- The space limitations: Some applications may have limited space for installing a silencer, which may require a compact design or a custom solution.

Benefits and limitations of absorption silencers

The primary benefit of absorption silencers is their ability to effectively reduce the noise level of industrial environments. This can help to improve worker safety, reduce the risk of noise-induced hearing loss, and improve overall working conditions. Additionally, absorption silencers are relatively easy to install and maintain, and they can be customized to meet the specific needs of each application.

However, absorption silencers do have some limitations. They may not be effective in reducing all types of noise, and they may not be suitable for applications with extremely high flow rates or operating temperatures. Additionally, some types of sound-absorbing materials may deteriorate over time, reducing the effectiveness of the silencer.

In conclusion, absorption silencers are a valuable tool for reducing noise levels in industrial environments. By selecting the right type of silencer for a specific application and ensuring proper installation and maintenance, it’s possible to achieve significant noise reduction and improve worker safety and productivity.

Advantages of Absorption Silencers:

- Effective Noise Reduction: The primary advantage of absorption silencers is their ability to effectively reduce noise levels in industrial environments. They are designed to absorb sound waves and convert them into heat energy, which significantly reduces the overall sound energy that is reflected back into the environment.

- Improved Safety and Productivity: By reducing noise levels in industrial environments, absorption silencers can help to improve worker safety and productivity. Excessive noise can lead to hearing damage, stress, and distraction, all of which can negatively impact worker performance.

- Customizable: Absorption silencers can be customized to meet the specific needs of each application. This allows for greater flexibility and adaptability in different industrial environments.

- Easy to Install and Maintain: Absorption silencers are relatively easy to install and maintain, which makes them a cost-effective solution for reducing noise levels in industrial settings.

Disadvantages of Absorption Silencers:

- Limited Effectiveness: Absorption silencers may not be effective in reducing all types of noise. In some cases, other types of silencers or noise reduction methods may be necessary.

- Deterioration Over Time: Some types of sound-absorbing materials used in absorption silencers may deteriorate over time, reducing their effectiveness. This means that regular maintenance and replacement may be necessary to maintain optimal performance.

- Size and Space Requirements: Depending on the specific application, absorption silencers may require a significant amount of space. This can be a challenge in applications with limited space or where there are other constraints.

- Cost: Absorption silencers can be expensive, especially if customized or specialized materials are required. This can make them less accessible for smaller businesses or applications with limited budgets.

Overall, absorption silencers are a valuable tool for reducing noise levels in industrial environments. While they do have some limitations, their effectiveness and customizability make them a popular choice for many applications. By carefully considering the specific needs and requirements of each application, it is possible to select an absorption silencer that provides optimal noise reduction and meets the unique challenges of each environment.