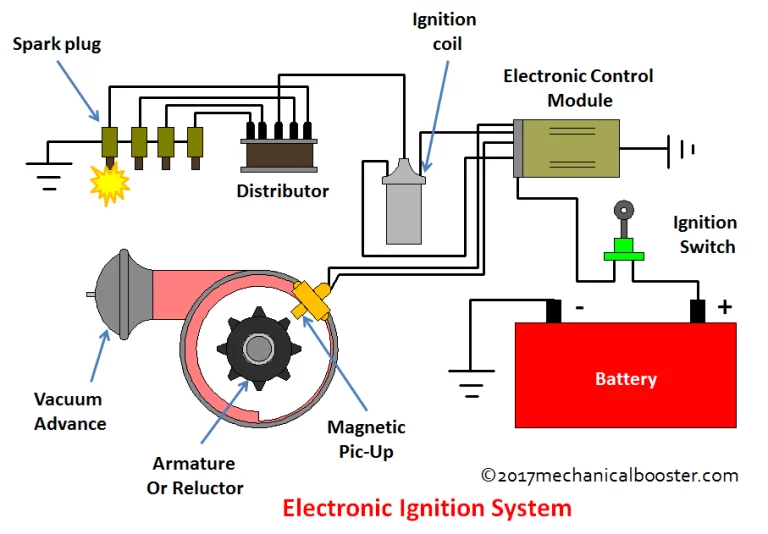

An electronic ignition distributor and ignition module are key components in a modern engine’s ignition system. They work together to ensure that the engine’s spark plugs receive the correct amount of electrical current at the right time, which is critical for reliable engine performance. In this blog, we’ll explore how electronic ignition distributors and ignition modules work and what benefits they offer over traditional mechanical ignition systems.

What is an Electronic Ignition Distributor?

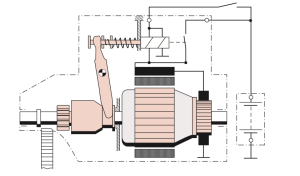

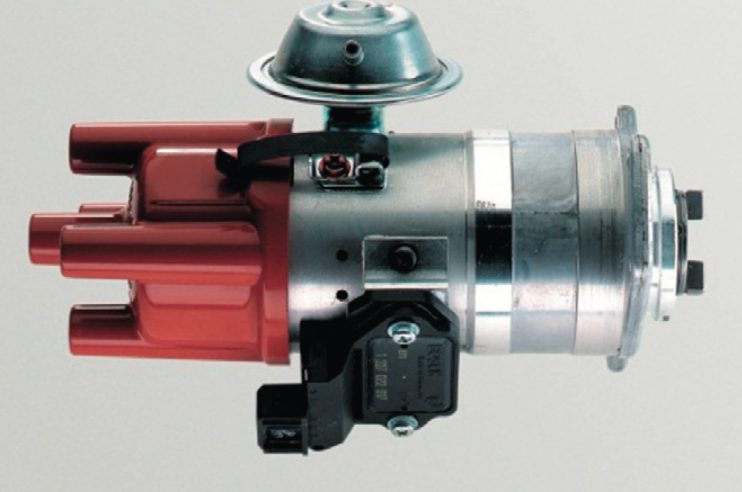

An electronic ignition distributor is a component that’s responsible for distributing electrical current from the ignition coil to the spark plugs. It does this by rotating a rotor inside the distributor cap, which is connected to the engine’s camshaft via a drive gear. As the rotor spins, it passes over a series of contacts that are connected to each spark plug wire, sending a high-voltage electrical current to the spark plug at the correct time in the engine’s cycle.

Electronic ignition distributors are typically more accurate and reliable than their mechanical counterparts. They use solid-state electronics to control the timing and duration of the spark, which means they’re less susceptible to wear and tear and can deliver more consistent performance over time. Additionally, electronic ignition distributors often feature adjustable advance curves, which allow the engine tuner to optimize ignition timing for maximum performance and efficiency.

What is an Ignition Module?

An ignition module is a component that works in conjunction with the electronic ignition distributor to control the timing and duration of the spark. It typically contains a microprocessor, which receives input from various sensors and switches that monitor engine speed, load, and temperature. Based on this information, the ignition module can adjust the timing and duration of the spark to ensure that the engine is running at peak performance.

Ignition modules can vary in their design and complexity, but they all share the common goal of optimizing ignition timing for maximum power and efficiency. Some ignition modules also offer additional features, such as rev limiters, which prevent the engine from over-revving and potentially causing damage.

Benefits of Electronic Ignition Distributors and Ignition Modules

There are several benefits to using electronic ignition distributors and ignition modules over traditional mechanical ignition systems. For one, they offer more precise control over ignition timing, which can improve engine performance and fuel efficiency. Additionally, electronic ignition systems are more reliable and require less maintenance than mechanical systems, which can save owners time and money in the long run.

Another advantage of electronic ignition systems is that they can provide better starting performance in cold weather. Because the electronic ignition system can deliver a more powerful spark, it’s able to ignite the fuel mixture more quickly and reliably, even in sub-zero temperatures.

Overall, electronic ignition distributors and ignition modules are essential components of modern engine ignition systems. By providing more precise control over ignition timing and duration, they can improve engine performance, fuel efficiency, and reliability, making them a popular choice for performance enthusiasts and everyday drivers alike.

One of the key advantages of electronic ignition systems is their ability to provide more precise control over ignition timing. In traditional mechanical ignition systems, the timing of the spark is determined by a set of mechanical components, such as a distributor shaft and advance weights. These components are subject to wear and tear over time, which can lead to inaccurate timing and poor engine performance.

Electronic ignition systems, on the other hand, use solid-state electronics to control the timing and duration of the spark. This allows for much greater precision and accuracy, which can improve engine performance, fuel efficiency, and emissions. Additionally, electronic ignition systems can adjust ignition timing based on various engine parameters, such as engine speed, load, and temperature, which can further optimize engine performance.

Another advantage of electronic ignition systems is their reliability and low maintenance requirements. Because electronic ignition systems have fewer moving parts than mechanical systems, there’s less opportunity for wear and tear to occur. Additionally, electronic ignition systems are less susceptible to moisture and other environmental factors, which can cause mechanical ignition systems to fail.

Electronic ignition systems can also provide better starting performance in cold weather. In traditional mechanical ignition systems, the spark produced by the ignition coil may not be powerful enough to ignite the fuel mixture in extremely cold temperatures. However, electronic ignition systems can deliver a more powerful spark, which can help to ignite the fuel mixture more quickly and reliably.

Overall, electronic ignition systems offer a number of advantages over traditional mechanical ignition systems. By providing more precise control over ignition timing and duration, they can improve engine performance, fuel efficiency, and reliability. Additionally, their low maintenance requirements and better cold weather starting performance make them a popular choice for many vehicle owners.

Advantages:

- Precise Ignition Timing: Electronic ignition systems can provide more precise control over ignition timing, which can improve engine performance, fuel efficiency, and emissions.

- Better Starting Performance: Electronic ignition systems can deliver a more powerful spark, which can help to ignite the fuel mixture more quickly and reliably, even in extremely cold temperatures.

- Improved Reliability: Electronic ignition systems have fewer moving parts than mechanical systems, which can make them more reliable and require less maintenance.

- Increased Durability: Electronic ignition systems are less susceptible to wear and tear from environmental factors, such as moisture, which can cause mechanical ignition systems to fail.

- Customizable Ignition Curves: Some electronic ignition systems allow for customizable ignition curves, which can be optimized for maximum performance and efficiency.

Disadvantages:

- Cost: Electronic ignition systems can be more expensive than traditional mechanical ignition systems.

- Complexity: Electronic ignition systems are more complex than mechanical systems, which can make them more difficult to diagnose and repair.

- Compatibility Issues: Some older vehicles may not be compatible with electronic ignition systems without significant modification or retrofitting.

- Power Consumption: Electronic ignition systems require a constant source of electrical power, which can increase power consumption and potentially decrease fuel efficiency.

- Potential Interference: Electronic ignition systems can be susceptible to electromagnetic interference, which can cause erratic performance or failure.