Thermostatic expansion valves (TXVs) are essential components of refrigeration and air conditioning systems that regulate the flow of refrigerant into the evaporator coil. They are also known as thermal expansion valves (TEVs) or simply expansion valves.

The primary function of a thermostatic expansion valve is to control the amount of refrigerant flowing into the evaporator coil, based on the evaporator’s cooling load. By regulating the refrigerant flow, the valve ensures that the evaporator is operating at the correct pressure and temperature, which maximizes the system’s efficiency and cooling capacity.

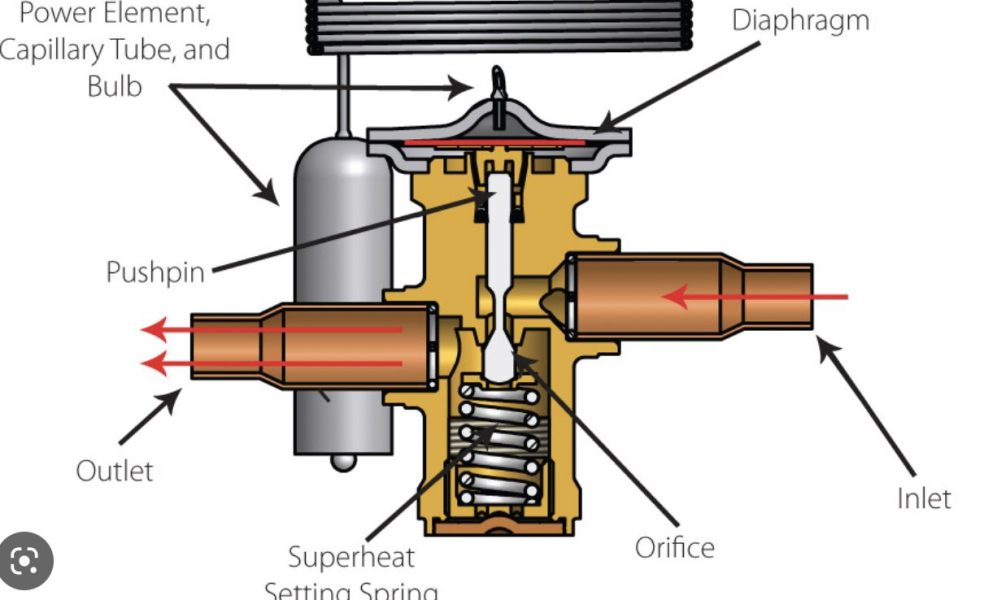

The thermostatic expansion valve consists of several components, including a sensing bulb, valve body, diaphragm, and valve seat. The sensing bulb is attached to the suction line of the evaporator coil and contains a temperature-sensitive liquid that expands or contracts depending on the temperature of the refrigerant flowing through the coil.

When the temperature in the evaporator coil drops below the set point, the refrigerant in the sensing bulb also cools, causing the liquid inside to contract. This contraction exerts a force on the diaphragm inside the valve, which opens the valve seat, allowing more refrigerant to flow into the evaporator coil. Conversely, when the temperature in the evaporator coil rises above the set point, the refrigerant in the sensing bulb warms up, causing the liquid inside to expand. This expansion exerts a force on the diaphragm that closes the valve seat, reducing the flow of refrigerant into the evaporator coil.

The thermostatic expansion valve’s ability to respond to changes in evaporator temperature makes it an important component of any refrigeration or air conditioning system. Proper installation and adjustment of the valve are critical to ensuring that the system operates efficiently and reliably. If the valve is not calibrated correctly, it can cause a range of problems, including poor cooling performance, high energy consumption, and compressor failure.

In summary, thermostatic expansion valves play a critical role in regulating the flow of refrigerant into the evaporator coil of refrigeration and air conditioning systems. By responding to changes in evaporator temperature, the valve ensures that the system operates efficiently and reliably. Proper installation and adjustment of the valve are essential for optimal system performance.

One of the key advantages of using a thermostatic expansion valve in a refrigeration or air conditioning system is that it allows for precise control of the refrigerant flow. This is important because the amount of refrigerant that enters the evaporator coil directly affects the cooling capacity of the system. If too much refrigerant enters the evaporator, it can lead to flooding and reduced efficiency. If too little refrigerant enters the evaporator, it can lead to insufficient cooling.

Thermostatic expansion valves are designed to respond to changes in evaporator temperature, which makes them ideal for use in systems that have varying cooling loads. For example, in an air conditioning system, the cooling load can change depending on factors such as the outdoor temperature, the number of people in the room, and the heat generated by electronic devices. The thermostatic expansion valve ensures that the amount of refrigerant flowing into the evaporator matches the cooling load, which maximizes the system’s efficiency and cooling capacity.

Another advantage of using a thermostatic expansion valve is that it can help prevent compressor damage. If too much refrigerant enters the evaporator coil, it can cause liquid slugging, which can damage the compressor. Liquid slugging occurs when liquid refrigerant enters the compressor, and the compressor tries to compress it. This can lead to mechanical damage, including broken valves, bent pistons, and damaged bearings. By controlling the flow of refrigerant into the evaporator, the thermostatic expansion valve helps prevent liquid slugging and protects the compressor.

Proper installation and adjustment of the thermostatic expansion valve are critical to ensuring optimal system performance. If the valve is not installed correctly or calibrated properly, it can cause a range of problems, including poor cooling performance, high energy consumption, and compressor failure. It’s important to follow the manufacturer’s guidelines when installing and adjusting the valve to ensure that it is working correctly.

In summary, thermostatic expansion valves are important components of refrigeration and air conditioning systems that regulate the flow of refrigerant into the evaporator coil. They allow for precise control of the refrigerant flow, prevent compressor damage, and maximize system efficiency and cooling capacity. Proper installation and adjustment of the valve are essential for optimal system performance.

Thermostatic expansion valves (TXVs) have several advantages and disadvantages, which are important to consider when designing and installing refrigeration and air conditioning systems.

Advantages:

- Precise Control: The primary advantage of a thermostatic expansion valve is its ability to provide precise control over the refrigerant flow. By regulating the amount of refrigerant entering the evaporator coil, the valve ensures that the cooling load is matched to the system’s capacity. This results in improved energy efficiency and cooling performance.

- Protection: Thermostatic expansion valves help protect the compressor by preventing liquid slugging. By regulating the flow of refrigerant, the valve ensures that only vapor enters the compressor, preventing damage due to liquid slugging.

- Flexibility: Thermostatic expansion valves are flexible and can be used in a variety of systems with different cooling loads. They can also be used with different refrigerants, making them a versatile option for a range of applications.

Disadvantages:

- Complexity: Thermostatic expansion valves are more complex than other types of expansion devices, which can make installation and adjustment more challenging. The valve must be properly calibrated to ensure that it is functioning correctly, which can require specialized equipment and expertise.

- Cost: Thermostatic expansion valves are more expensive than other types of expansion devices, which can make them less cost-effective for smaller systems or those with lower cooling loads.

- Maintenance: Thermostatic expansion valves require regular maintenance to ensure that they are functioning correctly. The sensing bulb must be kept clean and free of debris, and the valve must be inspected and calibrated periodically to ensure optimal performance.

In summary, thermostatic expansion valves provide precise control over the refrigerant flow and protect the compressor from damage due to liquid slugging. However, they are more complex and expensive than other types of expansion devices and require regular maintenance to ensure optimal performance. When selecting an expansion device for a refrigeration or air conditioning system, it’s important to consider the advantages and disadvantages of each option and choose the device that best meets the system’s needs.