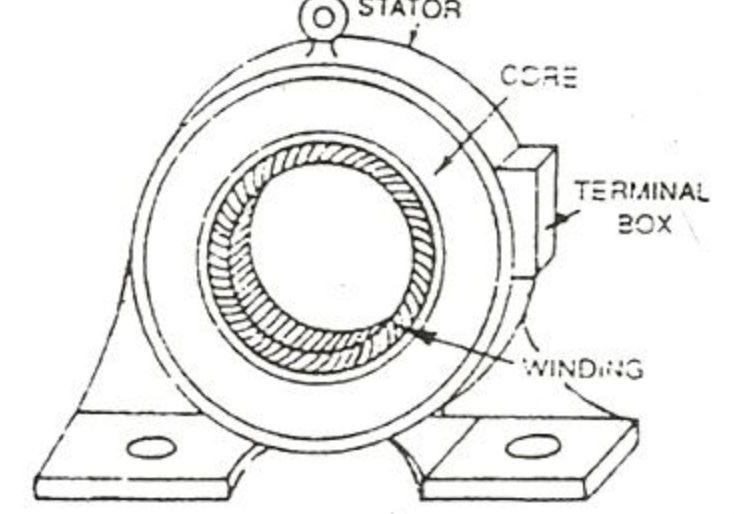

The stator is a crucial component of an electric motor, and it is responsible for generating the magnetic field that interacts with the rotor to produce rotational movement. The stator is a stationary part of the motor, which means it does not rotate, and it is typically constructed using a variety of materials and designs to suit different applications.

In this article, we will take a closer look at stator construction and the materials and design considerations that are involved.

Materials Used in Stator Construction

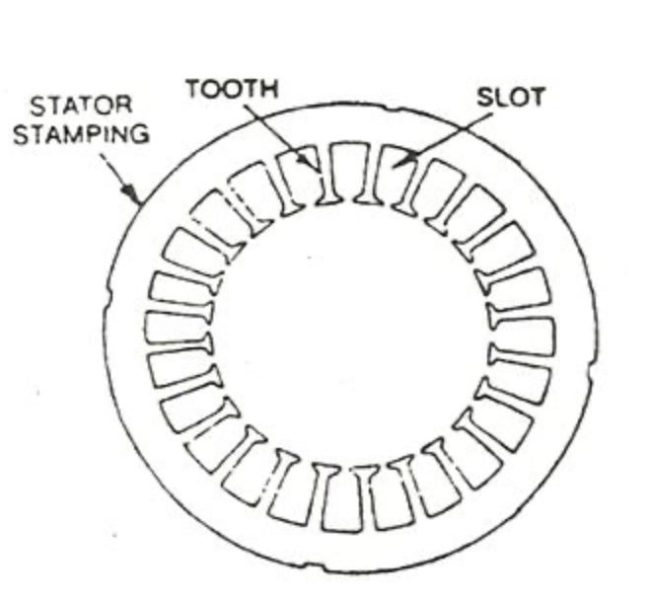

The stator is typically constructed using laminated magnetic steel sheets that are stacked together to form a cylindrical or rectangular shape. The laminations are coated with an insulating material to prevent the formation of eddy currents and reduce energy losses due to heat. The thickness of the laminations can vary, depending on the size and power rating of the motor, and they are usually thinner for smaller motors.

The wire used to wind the stator coils is typically made from copper or aluminum, depending on the specific requirements of the motor. Copper wire is more expensive than aluminum wire, but it has better conductivity and lower resistance, which means it can carry more current without overheating. Aluminum wire is lighter and less expensive than copper wire, but it has higher resistance and lower conductivity, which can lead to increased heat generation.

Design Considerations for Stator Construction

The design of the stator is critical to the performance of the motor, and several factors must be considered when designing a stator. These factors include the number of poles, the number of turns per coil, the size and shape of the stator core, and the winding pattern of the coils.

The number of poles on the stator determines the speed of the motor and the torque it can produce. Motors with more poles typically have lower speeds and higher torque, while motors with fewer poles have higher speeds and lower torque.

The number of turns per coil affects the strength of the magnetic field generated by the stator. More turns per coil result in a stronger magnetic field, which can lead to higher motor efficiency and torque output.

The size and shape of the stator core can vary depending on the specific application of the motor. For example, motors used in industrial applications typically have larger stator cores than motors used in household appliances.

The winding pattern of the coils can also affect motor performance. There are several winding patterns used in stator construction, including concentric, lap, and wave winding. Each winding pattern has its own advantages and disadvantages, depending on the specific requirements of the motor.

Conclusion

In conclusion, stator construction is a critical aspect of electric motor design, and it involves careful consideration of the materials and design factors that affect motor performance. The stator is typically constructed using laminated magnetic steel sheets and copper or aluminum wire, and the design considerations include the number of poles, the number of turns per coil, the size and shape of the stator core, and the winding pattern of the coils. By optimizing these design factors, motor manufacturers can produce efficient and reliable motors that are suited to a wide range of applications.

Stator construction involves the use of laminated magnetic steel sheets that are stacked together to form a core. The laminations are coated with an insulating material to prevent the formation of eddy currents, which can cause energy losses and reduce motor efficiency. The thickness of the laminations can vary, depending on the size and power rating of the motor, and thinner laminations are typically used in smaller motors to reduce material costs.

The wire used to wind the stator coils is another important consideration in stator construction. Copper wire is a popular choice for stator winding because it has better conductivity and lower resistance than aluminum wire. This means that it can carry more current without overheating and can produce higher torque output. However, copper wire is more expensive than aluminum wire, which can make it less cost-effective for some applications. Aluminum wire is lighter and less expensive than copper wire, but it has higher resistance and lower conductivity, which can result in increased heat generation and reduced efficiency.

The number of poles on the stator is another critical factor in motor design. The poles are the magnetic north and south poles that are created by the stator’s magnetic field, and the number of poles determines the speed and torque of the motor. Motors with more poles typically have lower speeds and higher torque, while motors with fewer poles have higher speeds and lower torque. The number of turns per coil can also affect motor performance, with more turns per coil resulting in a stronger magnetic field and higher motor efficiency.

The size and shape of the stator core can also vary depending on the specific application of the motor. Motors used in industrial applications typically have larger stator cores than motors used in household appliances. The winding pattern of the coils can also affect motor performance, with different winding patterns offering different advantages and disadvantages. Concentric winding, for example, is a simple and efficient winding pattern that is commonly used in smaller motors, while wave winding is a more complex winding pattern that can offer higher efficiency and torque output.

In conclusion, stator construction is a critical aspect of electric motor design that involves careful consideration of materials and design factors to optimize motor performance. By choosing the right materials and design factors, motor manufacturers can produce efficient and reliable motors that are suited to a wide range of applications.

Advantages of Stator Construction:

- High Efficiency: Stator construction using laminated magnetic steel sheets and high-quality copper wire can result in a high-efficiency motor that can convert electrical energy into mechanical energy with minimal energy loss.

- Low Maintenance: The stator is a stationary part of the motor and does not require any moving parts, which reduces maintenance needs and extends the lifespan of the motor.

- Versatility: Stator construction can be adapted to suit a wide range of applications and motor sizes, making it a versatile option for motor manufacturers.

- Cost-Effective: Stator construction using cost-effective materials like aluminum wire and thinner laminations can help reduce the overall cost of the motor without compromising performance.

Disadvantages of Stator Construction:

- Limited Speed Range: The number of poles on the stator determines the motor speed range, which can be limited in some cases, making it challenging to optimize the motor for a specific application.

- Heating Issues: Stator construction using lower-quality materials or insufficient cooling can result in excessive heat generation, which can reduce motor efficiency and lifespan.

- Complexity: Stator construction can be a complex process that requires precise winding patterns and materials to optimize motor performance, which can increase manufacturing costs and complexity.

- Size Limitations: Stator construction using laminated magnetic steel sheets and copper wire can result in a larger and heavier motor compared to other motor types, which can be a disadvantage in some applications where space is limited.

In conclusion, stator construction offers many advantages, including high efficiency, low maintenance, and versatility, but it also has some disadvantages, including limited speed range, heating issues, complexity, and size limitations. Overall, the choice of stator construction depends on the specific requirements of the motor and the application it will be used for.