Solenoid valve-controlled radial-piston distributor pumps are an essential component in many hydraulic systems. They are primarily used to distribute hydraulic fluid from a reservoir to various parts of the system. In this blog, we will explore the workings of a solenoid valve-controlled radial-piston distributor pump and its applications.

What is a solenoid valve-controlled radial-piston distributor pump?

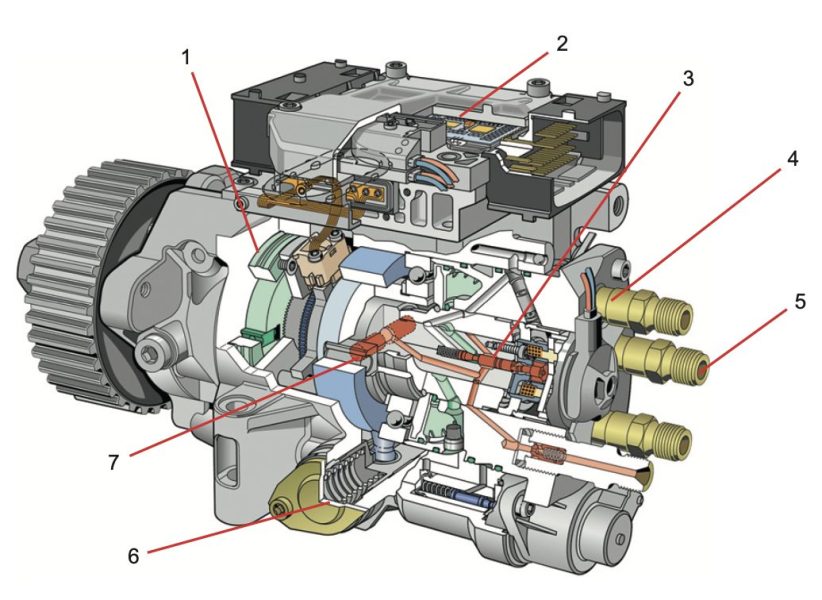

A solenoid valve-controlled radial-piston distributor pump is a type of hydraulic pump that uses a radial piston design to distribute hydraulic fluid to different parts of a hydraulic system. The pump consists of a series of radial pistons arranged around a central camshaft. The camshaft rotates, and the pistons are forced in and out of their cylinders by the action of the cam.

The solenoid valve is used to control the flow of hydraulic fluid to the pump. When the solenoid valve is open, hydraulic fluid is allowed to flow into the pump, and the pistons are pushed outward, creating a positive displacement of the fluid. When the solenoid valve is closed, the pistons are pushed back into their cylinders, and the fluid is displaced out of the pump.

Applications of solenoid valve-controlled radial-piston distributor pump

Solenoid valve-controlled radial-piston distributor pumps are commonly used in hydraulic systems that require accurate control of fluid flow. They are often found in machinery used in the construction, manufacturing, and automotive industries. Here are some common applications of solenoid valve-controlled radial-piston distributor pumps:

- Machine tools: Radial-piston distributor pumps are widely used in machine tools to provide the hydraulic power required for the operation of different machine components such as clamping and feeding systems.

- Injection molding machines: Injection molding machines use hydraulic systems to operate their different components. Solenoid valve-controlled radial-piston distributor pumps are used to provide the high-pressure fluid required for the injection molding process.

- Automotive industry: Hydraulic systems are widely used in the automotive industry for various functions such as power steering, brakes, and suspensions. Solenoid valve-controlled radial-piston distributor pumps are commonly used in these systems to provide the required fluid flow and pressure.

Advantages of solenoid valve-controlled radial-piston distributor pump

There are several advantages of using solenoid valve-controlled radial-piston distributor pumps in hydraulic systems. Here are some of them:

- High precision: Radial-piston distributor pumps are highly precise and can deliver accurate and consistent fluid flow, making them ideal for applications that require precise control.

- High efficiency: Solenoid valve-controlled radial-piston distributor pumps are highly efficient and can generate high pressure with minimal energy consumption.

- Compact design: Radial-piston distributor pumps have a compact design, making them suitable for use in applications where space is limited.

- Low noise: Solenoid valve-controlled radial-piston distributor pumps operate with minimal noise, making them suitable for use in applications where noise levels need to be kept to a minimum.

Conclusion

Solenoid valve-controlled radial-piston distributor pumps are an important component in many hydraulic systems. Their high precision, efficiency, and compact design make them ideal for use in a wide range of applications. With their ability to deliver accurate and consistent fluid flow, these pumps play a critical role in the smooth and efficient operation of hydraulic systems in various industries.

Certainly! Let’s dive a bit deeper into the working principles of solenoid valve-controlled radial-piston distributor pumps and their advantages.

Solenoid valve-controlled radial-piston distributor pumps work on the principle of positive displacement. They use a series of radial pistons, which are arranged around a central camshaft. The camshaft is driven by an external power source, such as an electric motor, and rotates at a constant speed. The pistons are in contact with the camshaft and are forced in and out of their cylinders by the action of the cam.

The solenoid valve is used to control the flow of hydraulic fluid into the pump. When the solenoid valve is open, the hydraulic fluid flows into the pump, and the pistons are pushed outward by the camshaft. This creates a positive displacement of the fluid, which is then distributed to different parts of the hydraulic system. When the solenoid valve is closed, the pistons are pushed back into their cylinders by the action of the camshaft, and the fluid is displaced out of the pump.

Advantages of solenoid valve-controlled radial-piston distributor pumps

- High precision: Radial-piston distributor pumps are highly precise and can deliver accurate and consistent fluid flow. This is because they operate on the principle of positive displacement, which ensures that the same amount of fluid is displaced every time the pump completes a cycle.

- High efficiency: Solenoid valve-controlled radial-piston distributor pumps are highly efficient and can generate high pressure with minimal energy consumption. This is because the pistons operate on a radial motion, which ensures that there is minimal friction between the moving parts.

- Compact design: Radial-piston distributor pumps have a compact design, making them suitable for use in applications where space is limited. The pistons are arranged around a central camshaft, which means that the overall size of the pump is relatively small compared to other types of hydraulic pumps.

- Low noise: Solenoid valve-controlled radial-piston distributor pumps operate with minimal noise, making them suitable for use in applications where noise levels need to be kept to a minimum. This is because the pistons operate on a radial motion, which ensures that there is minimal vibration and noise generated by the moving parts.

In summary, solenoid valve-controlled radial-piston distributor pumps are a reliable and efficient component in hydraulic systems. Their high precision, efficiency, compact design, and low noise operation make them ideal for use in a wide range of applications. From machine tools and injection molding machines to the automotive industry, these pumps play a critical role in ensuring the smooth and efficient operation of hydraulic systems.

Advantages:

- Precise and consistent fluid flow: The positive displacement principle used by solenoid valve-controlled radial-piston distributor pumps ensures that they can deliver accurate and consistent fluid flow.

- High efficiency: These pumps are highly efficient and can generate high pressure with minimal energy consumption.

- Compact design: Their compact design makes them suitable for use in applications where space is limited.

- Low noise: These pumps operate with minimal noise, making them ideal for use in applications where noise levels need to be kept to a minimum.

- Long service life: These pumps are durable and can last a long time with minimal maintenance.

Disadvantages:

- Higher cost: Compared to other types of hydraulic pumps, solenoid valve-controlled radial-piston distributor pumps can be more expensive.

- Limited speed range: These pumps have a limited speed range and may not be suitable for applications that require high-speed fluid flow.

- Limited flow rate: The flow rate of these pumps may be limited, depending on the number and size of the pistons used.

- Limited viscosity range: These pumps may not be suitable for applications that require a wide range of fluid viscosities.

- Complex design: These pumps have a more complex design compared to other types of hydraulic pumps, which can make maintenance and repair more challenging.

Overall, solenoid valve-controlled radial-piston distributor pumps are reliable and efficient components for hydraulic systems. However, their specific advantages and disadvantages should be carefully considered when selecting a pump for a particular application.