A heavy-duty starter motor is an essential component of any heavy-duty vehicle, including trucks, buses, construction equipment, and agricultural machinery. It plays a critical role in starting the engine and ensuring that the vehicle is ready to perform its intended functions.

In this blog, we’ll take a closer look at what a heavy-duty starter motor is, how it works, and why it is essential for heavy-duty vehicles.

What is a heavy-duty starter motor?

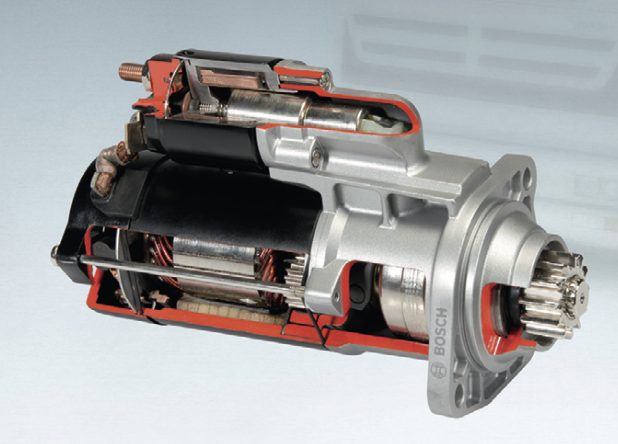

A starter motor is an electric motor that is responsible for turning over an internal combustion engine to start it. A heavy-duty starter motor is specifically designed to handle the higher demands of heavy-duty vehicles that require more power to start their engines.

Heavy-duty starter motors are typically larger and more robust than their smaller counterparts used in lighter vehicles. They have more powerful motors, heavier-duty gears, and larger solenoids to withstand the additional load and torque required to start heavy-duty engines.

How does a heavy-duty starter motor work?

A heavy-duty starter motor works in much the same way as a standard starter motor, but with additional features to make it more durable and efficient. The motor receives power from the vehicle’s battery and uses that power to turn the engine’s flywheel, which then starts the engine.

The heavy-duty starter motor is designed to handle the higher load and torque demands of heavy-duty engines. To do this, it typically has a more powerful motor and heavier-duty gears than a standard starter motor.

Additionally, heavy-duty starter motors often have larger solenoids that can handle the additional current required to turn over a heavy-duty engine. Solenoids are electromagnetic devices that engage the starter motor’s pinion gear with the engine’s flywheel.

Why is a heavy-duty starter motor important for heavy-duty vehicles?

Heavy-duty starter motors are essential for heavy-duty vehicles because they can handle the higher demands of starting larger and more powerful engines. Without a heavy-duty starter motor, the engine may not start at all, or it may take longer to start, causing delays and potentially damaging the engine.

In addition to being more robust, heavy-duty starter motors are also designed to be more reliable and durable than standard starter motors. Heavy-duty vehicles often operate in harsh environments, including extreme temperatures, dust, and debris. A heavy-duty starter motor must be able to withstand these conditions without failing.

Final thoughts

A heavy-duty starter motor is a crucial component of any heavy-duty vehicle. It is responsible for starting the engine and ensuring that the vehicle is ready to perform its intended functions. If you’re in the market for a heavy-duty starter motor, be sure to choose one that is specifically designed for your vehicle and its engine size. Investing in a high-quality heavy-duty starter motor can save you time and money in the long run by reducing the risk of engine damage and downtime.

Heavy-duty starter motors are designed to handle the higher load and torque requirements of heavy-duty engines. They typically have more powerful motors, heavier-duty gears, and larger solenoids than standard starter motors. These components are built to withstand the additional strain of starting heavy-duty engines.

The motor of a heavy-duty starter motor is usually larger than that of a standard starter motor. This allows it to generate more torque, which is needed to turn over larger and more powerful engines. The motor is also designed to handle the higher current draw required to turn over heavy-duty engines.

The gears of a heavy-duty starter motor are also built to be more robust than those of a standard starter motor. Heavy-duty starter motors often use spur gears or helical gears, which are stronger and more durable than the smaller and lighter planetary gears commonly used in standard starter motors. These gears are designed to withstand the additional load and torque requirements of heavy-duty engines.

The solenoid of a heavy-duty starter motor is typically larger than that of a standard starter motor. This allows it to handle the higher current required to engage the starter motor’s pinion gear with the engine’s flywheel. The solenoid is also designed to be more durable and reliable, as heavy-duty vehicles often operate in harsh environments.

In addition to the mechanical components, heavy-duty starter motors may also have electronic features to improve their performance and reliability. For example, some heavy-duty starter motors have built-in sensors that can detect when the engine is starting to turn over and adjust the starter motor’s output accordingly. This can help to prevent the starter motor from stalling or overheating.

Overall, a heavy-duty starter motor is a critical component of any heavy-duty vehicle. It is designed to handle the higher load and torque requirements of heavy-duty engines and operate reliably in harsh environments. Investing in a high-quality heavy-duty starter motor can help to prevent engine damage, reduce downtime, and save you time and money in the long run.

Advantages of Heavy-Duty Starter Motors:

- Increased durability: Heavy-duty starter motors are built to last longer than standard starter motors. They are made with more durable materials and can withstand the harsh conditions that heavy-duty vehicles often operate in.

- Improved reliability: Heavy-duty starter motors are designed to be more reliable than standard starter motors. They have larger and more robust components that are less likely to fail.

- Greater torque: Heavy-duty starter motors have larger motors that can generate more torque than standard starter motors. This allows them to turn over larger and more powerful engines.

- Faster starting: Heavy-duty starter motors can start engines more quickly than standard starter motors. This can be particularly important in situations where a vehicle needs to be started quickly, such as in emergency situations.

Disadvantages of Heavy-Duty Starter Motors:

- Higher cost: Heavy-duty starter motors are generally more expensive than standard starter motors. This can make them less appealing to some buyers who are looking to save money.

- Increased weight: Heavy-duty starter motors are larger and heavier than standard starter motors. This can add weight to the vehicle, which can reduce fuel efficiency and increase the overall weight of the vehicle.

- More complex: Heavy-duty starter motors have more complex components than standard starter motors. This can make them more difficult to repair or replace if they fail.

- Limited compatibility: Heavy-duty starter motors may not be compatible with all types of heavy-duty vehicles. It is important to make sure that the starter motor is designed to work with your specific vehicle before making a purchase.

In summary, heavy-duty starter motors have many advantages, including increased durability, improved reliability, greater torque, and faster starting. However, they also have some disadvantages, such as higher cost, increased weight, more complexity, and limited compatibility. It is important to carefully consider the pros and cons of heavy-duty starter motors before making a purchase to ensure that they are the right choice for your vehicle.