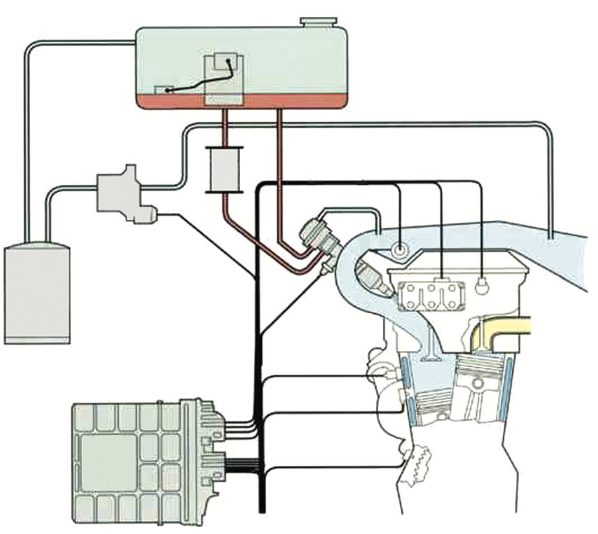

Fuel supply components are an essential part of any combustion engine, as they ensure a steady flow of fuel to the engine’s combustion chamber. The fuel supply system includes several components that work together to deliver fuel to the engine. In this blog, we will discuss the fuel supply components shown in red, which are crucial for maintaining a reliable fuel supply system.

- Fuel Pump:

The fuel pump is responsible for drawing fuel from the fuel tank and delivering it to the engine. There are two types of fuel pumps: mechanical and electric. Mechanical fuel pumps are driven by the engine’s motion, while electric fuel pumps are powered by an electric motor. The fuel pump’s job is to maintain a constant flow of fuel to the engine, regardless of the engine’s speed.

- Fuel Filter:

The fuel filter is an important component that ensures that the fuel that reaches the engine is free of contaminants. The fuel filter is designed to remove impurities such as dirt, rust, and debris from the fuel before it enters the engine. A clogged fuel filter can cause a drop in engine performance and even engine damage.

- Fuel Pressure Regulator:

The fuel pressure regulator controls the pressure of the fuel that enters the engine. It is responsible for maintaining a constant fuel pressure in the fuel lines, regardless of the engine’s demand for fuel. If the fuel pressure regulator fails, it can cause fuel pressure to drop or rise, leading to engine performance issues.

- Fuel Injector:

The fuel injector is responsible for delivering fuel to the engine’s combustion chamber. The fuel injector is a small, electrically operated valve that opens and closes in response to signals from the engine’s electronic control unit (ECU). The fuel injector delivers fuel in a fine mist, which ensures complete combustion and reduces emissions.

- Fuel Rail:

The fuel rail is a tube that connects the fuel injectors to the fuel supply line. It is responsible for distributing fuel evenly to each fuel injector. The fuel rail also acts as a pressure regulator, ensuring that the fuel pressure is constant and consistent across all fuel injectors.

In conclusion, fuel supply components are crucial for maintaining a reliable and efficient fuel supply system. The components discussed above work together to deliver a constant flow of clean fuel to the engine’s combustion chamber, ensuring optimal engine performance and longevity. Proper maintenance of these components is crucial to avoid engine damage and ensure a long and trouble-free service life.

- Fuel Pump: The fuel pump is the heart of the fuel supply system, as it draws fuel from the fuel tank and delivers it to the engine. A mechanical fuel pump is usually located on the engine block and is driven by a camshaft, while an electric fuel pump is located in the fuel tank and is powered by the vehicle’s electrical system. The fuel pump’s job is to maintain a constant flow of fuel to the engine, regardless of the engine’s speed. If the fuel pump fails, it can cause a lack of power, rough idling, and stalling.

- Fuel Filter: The fuel filter is responsible for removing impurities such as dirt, rust, and debris from the fuel before it enters the engine. It is usually located along the fuel supply line, between the fuel tank and the engine. Over time, the fuel filter can become clogged with contaminants, causing a drop in engine performance and even engine damage. It is important to replace the fuel filter regularly to prevent these issues.

- Fuel Pressure Regulator: The fuel pressure regulator controls the pressure of the fuel that enters the engine. It is usually located on the fuel rail, which is a tube that connects the fuel injectors to the fuel supply line. The fuel pressure regulator ensures that the fuel pressure remains constant, regardless of the engine’s demand for fuel. If the fuel pressure regulator fails, it can cause a drop or rise in fuel pressure, leading to engine performance issues.

- Fuel Injector: The fuel injector is responsible for delivering fuel to the engine’s combustion chamber. It is a small, electrically operated valve that opens and closes in response to signals from the engine’s electronic control unit (ECU). The fuel injector delivers fuel in a fine mist, which ensures complete combustion and reduces emissions. Over time, fuel injectors can become clogged with dirt and debris, leading to engine performance issues. It is important to clean or replace the fuel injectors regularly to prevent these issues.

- Fuel Rail: The fuel rail is a tube that connects the fuel injectors to the fuel supply line. It is responsible for distributing fuel evenly to each fuel injector. The fuel rail also acts as a pressure regulator, ensuring that the fuel pressure is constant and consistent across all fuel injectors. The fuel rail can become clogged with debris or develop leaks, leading to engine performance issues. It is important to maintain the fuel rail to prevent these issues.

Overall, fuel supply components are crucial for maintaining a reliable and efficient fuel supply system. Proper maintenance and regular replacement of these components can help prevent engine damage and ensure a long and trouble-free service life.

Advantages of Fuel Supply Components:

- Reliable Fuel Delivery: The fuel supply components work together to deliver a constant and reliable flow of fuel to the engine, ensuring optimal engine performance and efficiency.

- Reduced Emissions: The fuel supply components ensure that the fuel is properly filtered and atomized, leading to more complete combustion and reduced emissions.

- Longevity: Proper maintenance of the fuel supply components can help extend the engine’s service life and prevent costly repairs.

- Fuel Efficiency: A well-maintained fuel supply system can help improve fuel efficiency, leading to cost savings over time.

Disadvantages of Fuel Supply Components:

- Cost: Fuel supply components can be expensive to replace, especially if they require specialized tools or professional installation.

- Maintenance: Regular maintenance is required to ensure the fuel supply components are functioning correctly, which can be time-consuming and costly.

- Failure: If a fuel supply component fails, it can lead to engine performance issues, stalling, or even engine damage.

- Complexity: Fuel supply systems can be complex and require specialized knowledge to diagnose and repair issues.

In conclusion, while fuel supply components are essential for maintaining a reliable and efficient fuel supply system, they also have some disadvantages, including cost, maintenance requirements, potential failure, and complexity. However, the benefits of reliable fuel delivery, reduced emissions, longevity, and fuel efficiency generally outweigh the drawbacks. Proper maintenance and regular replacement of fuel supply components can help prevent issues and ensure optimal engine performance and longevity.