A fuel pressure regulator is an important component in the fuel system of a vehicle. It is responsible for regulating the fuel pressure that goes into the engine. A fuel pressure regulator on rail is a type of fuel pressure regulator that is used in modern fuel injection systems. In this blog, we will discuss what a fuel pressure regulator on rail is, how it works, and why it is important.

What is a fuel pressure regulator on rail?

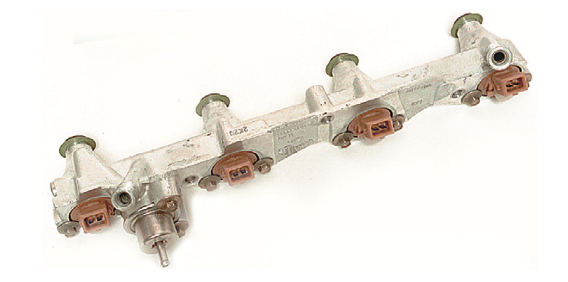

A fuel pressure regulator on rail is a type of fuel pressure regulator that is mounted on the fuel rail of a fuel injection system. The fuel rail is the component that delivers fuel to the fuel injectors. The fuel pressure regulator on rail is responsible for regulating the fuel pressure that goes into the fuel injectors.

How does a fuel pressure regulator on rail work?

A fuel pressure regulator on rail works by monitoring the fuel pressure in the fuel rail and adjusting it as necessary. It is connected to the fuel rail by a hose or pipe, and it uses a diaphragm and spring to regulate the fuel pressure.

When the fuel pressure in the fuel rail is too high, the diaphragm in the fuel pressure regulator on rail is pushed upward against the spring, causing the fuel pressure to decrease. When the fuel pressure in the fuel rail is too low, the diaphragm in the fuel pressure regulator on rail is pushed downward by the spring, causing the fuel pressure to increase.

Why is a fuel pressure regulator on rail important?

A fuel pressure regulator on rail is important because it ensures that the fuel pressure going into the fuel injectors is at the correct level. If the fuel pressure is too high, it can cause the fuel injectors to malfunction, which can lead to poor engine performance, reduced fuel economy, and even engine damage. If the fuel pressure is too low, the engine may not start or may run poorly.

In addition to regulating the fuel pressure, a fuel pressure regulator on rail also helps to prevent fuel vaporization. Fuel vaporization can occur when the fuel temperature is high, which can cause the fuel to evaporate and form air bubbles in the fuel line. These air bubbles can cause the fuel injectors to malfunction, which can lead to poor engine performance.

Conclusion

In summary, a fuel pressure regulator on rail is an important component in the fuel system of a vehicle. It regulates the fuel pressure that goes into the fuel injectors, which is essential for proper engine performance. By ensuring that the fuel pressure is at the correct level, a fuel pressure regulator on rail helps to prevent engine damage, reduce fuel consumption, and improve overall engine performance.

As mentioned earlier, a fuel pressure regulator on rail is responsible for regulating the fuel pressure that goes into the fuel injectors. This is important because fuel injectors require a certain level of pressure to properly atomize the fuel and deliver it to the engine for combustion. If the fuel pressure is too low, the injectors may not be able to spray the fuel properly, leading to incomplete combustion and poor engine performance. On the other hand, if the fuel pressure is too high, the injectors may be overpowered and deliver too much fuel, which can also result in poor performance, reduced fuel economy, and engine damage.

In addition to regulating fuel pressure, a fuel pressure regulator on rail can also help prevent fuel vaporization. Fuel vaporization occurs when the fuel temperature is high enough to cause the fuel to evaporate and form air bubbles in the fuel line. These air bubbles can cause the fuel injectors to malfunction, which can lead to poor engine performance, reduced fuel economy, and even engine damage. By maintaining proper fuel pressure, a fuel pressure regulator on rail can help prevent fuel vaporization from occurring.

A fuel pressure regulator on rail typically uses a spring and diaphragm system to regulate fuel pressure. The diaphragm separates the fuel side of the regulator from the air side, and changes in fuel pressure cause the diaphragm to move up or down against the spring. This movement controls a valve that regulates the fuel flow, and thus, the fuel pressure.

Some fuel pressure regulators on rail may be adjustable, which means that the fuel pressure can be manually adjusted to meet specific requirements or preferences. This can be useful for high-performance engines, where precise fuel pressure control is necessary to achieve optimal performance.

In summary, a fuel pressure regulator on rail plays a crucial role in the fuel system of a vehicle. It regulates fuel pressure to ensure proper engine performance, prevent fuel vaporization, and prevent engine damage. By understanding how it works and why it is important, vehicle owners can better maintain and troubleshoot their fuel systems to ensure optimal engine performance and longevity.

Advantages of a Fuel Pressure Regulator on Rail:

- Improved Engine Performance: The fuel pressure regulator on rail helps to maintain a consistent fuel pressure to the fuel injectors, which results in better atomization of fuel and more efficient combustion. This improves engine performance and helps to maximize power and fuel economy.

- Better Fuel Efficiency: By maintaining a consistent fuel pressure, the fuel pressure regulator on rail can help to improve fuel efficiency. This is because the engine is able to burn fuel more efficiently, which results in better fuel economy.

- Prevents Engine Damage: The fuel pressure regulator on rail helps to prevent engine damage by regulating fuel pressure. If the fuel pressure is too high, it can cause damage to the fuel injectors, while low fuel pressure can cause engine damage due to incomplete combustion. The fuel pressure regulator on rail ensures that the fuel pressure is always at the appropriate level.

- Prevents Fuel Vaporization: The fuel pressure regulator on rail can also help to prevent fuel vaporization. Fuel vaporization can lead to air bubbles in the fuel line, which can cause the fuel injectors to malfunction. The fuel pressure regulator on rail maintains the fuel pressure, which helps to prevent the formation of air bubbles in the fuel line.

Disadvantages of a Fuel Pressure Regulator on Rail:

- Cost: The fuel pressure regulator on rail is a more complex component than other types of fuel pressure regulators, which can make it more expensive to replace.

- Difficulty of Repair: The fuel pressure regulator on rail is a sealed unit, which means that it cannot be easily repaired. If the regulator fails, it typically needs to be replaced entirely.

- Limited Compatibility: The fuel pressure regulator on rail is designed specifically for use with fuel injection systems. It cannot be used with other types of fuel systems, such as carburetors.

- High Pressure System: The fuel pressure regulator on rail operates at high pressures, which can be dangerous if not handled properly. It is important to exercise caution when working with the fuel system to avoid injury.

In conclusion, while a fuel pressure regulator on rail offers several advantages, it is important to consider the potential disadvantages when deciding whether to use this type of fuel pressure regulator. The benefits of improved engine performance, fuel efficiency, and engine protection may outweigh the added cost and potential difficulties associated with this type of regulator.