In the world of diesel engines, fuel injection has undergone a revolution in recent years with the advent of common rail injection technology. The common rail injection system has become increasingly popular in diesel engines for cars, trucks, and heavy machinery, as it offers numerous advantages over traditional fuel injection systems. In this blog, we’ll take a closer look at common rail injection, its benefits, and how it works.

What is Common Rail Injection?

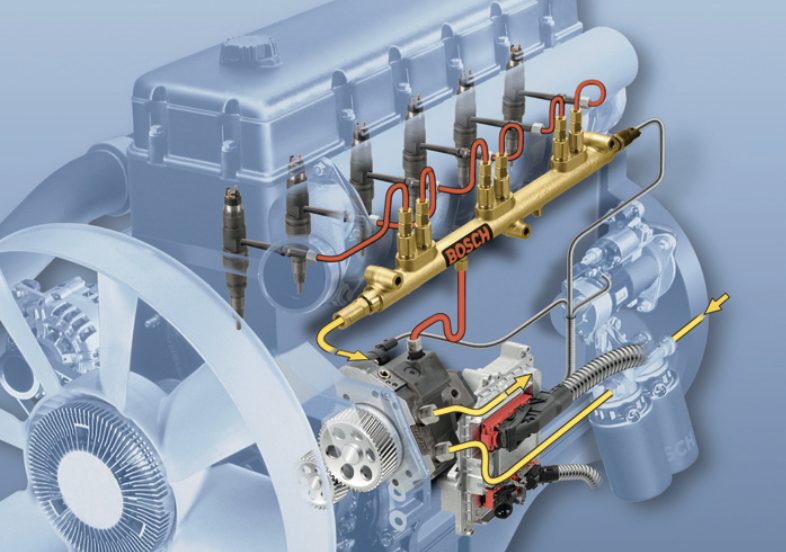

The common rail injection system is a type of fuel injection system that is designed to deliver high-pressure fuel directly to the engine’s combustion chamber. Unlike traditional fuel injection systems, which rely on a fuel pump to deliver fuel to the engine at a low pressure, common rail injection systems use a high-pressure fuel pump to deliver fuel to a common rail or fuel accumulator, which stores the fuel at high pressure until it’s needed by the engine.

How Does Common Rail Injection Work?

The common rail injection system consists of a high-pressure fuel pump, a fuel rail or accumulator, fuel injectors, and an electronic control unit (ECU). The high-pressure fuel pump is responsible for generating the high pressure required to deliver fuel to the engine. The fuel rail or accumulator stores the high-pressure fuel, which is then delivered to the injectors via high-pressure fuel lines.

The injectors are electronically controlled and are capable of delivering precise amounts of fuel to the engine at high pressure. The ECU monitors engine conditions, such as load and temperature, and adjusts the fuel delivery accordingly to ensure optimal performance and efficiency.

What are the Benefits of Common Rail Injection?

There are several advantages to using a common rail injection system in diesel engines. These include:

- Improved Fuel Efficiency – Common rail injection systems can deliver fuel at very high pressure, resulting in more efficient combustion and better fuel economy.

- Reduced Emissions – The precise fuel delivery of common rail injection systems results in reduced emissions, making them more environmentally friendly than traditional fuel injection systems.

- Better Performance – Common rail injection systems can deliver fuel in a more precise and controlled manner, resulting in better engine performance and response.

- Quieter Operation – The high-pressure fuel delivery of common rail injection systems results in quieter engine operation.

- Increased Durability – Common rail injection systems are generally more reliable and durable than traditional fuel injection systems, thanks to their electronically controlled injectors and precise fuel delivery.

Conclusion

In conclusion, common rail injection technology has revolutionized the world of diesel engines, offering numerous advantages over traditional fuel injection systems. With improved fuel efficiency, reduced emissions, better performance, and increased durability, it’s no wonder that common rail injection systems are becoming increasingly popular in diesel engines of all kinds.

- High-Pressure Fuel Delivery

One of the main advantages of common rail injection technology is its ability to deliver fuel at very high pressure. The high-pressure fuel delivery enables more efficient combustion, resulting in improved fuel efficiency and reduced emissions. By delivering fuel at higher pressure, the fuel atomizes more finely, allowing for more complete combustion and a more efficient use of fuel.

- Precise Fuel Control

Common rail injection systems are also known for their precise fuel control, which is achieved through electronically controlled fuel injectors. The injectors are controlled by an electronic control unit (ECU), which monitors engine conditions and adjusts the fuel delivery accordingly. This precise control allows for more efficient fuel consumption, better engine performance, and reduced emissions.

- Reduced Noise and Vibration

Another benefit of common rail injection technology is that it results in quieter engine operation. This is due to the high-pressure fuel delivery, which results in a more complete combustion and less engine noise. Additionally, the electronically controlled injectors allow for more precise fuel delivery, which can reduce engine vibration.

- Increased Durability

Common rail injection systems are also known for their durability and reliability. The electronically controlled injectors and precise fuel delivery result in less wear and tear on the engine, leading to longer engine life and reduced maintenance costs. Additionally, common rail injection systems are less susceptible to clogging and fuel system damage caused by impurities in the fuel.

- Improved Performance

Common rail injection technology can also lead to improved engine performance. The precise fuel delivery allows for more efficient combustion, resulting in better throttle response, more power, and improved acceleration. This can be particularly beneficial for vehicles that require a lot of power, such as heavy trucks and machinery.

Overall, common rail injection technology has revolutionized the world of diesel engines, offering numerous advantages over traditional fuel injection systems. By delivering fuel at high pressure and with precise control, common rail injection systems offer improved fuel efficiency, reduced emissions, better performance, and increased durability.

Advantages:

- Improved Fuel Efficiency: Common rail injection technology can deliver fuel at very high pressure, resulting in more efficient combustion and better fuel economy.

- Reduced Emissions: The precise fuel delivery of common rail injection systems results in reduced emissions, making them more environmentally friendly than traditional fuel injection systems.

- Better Performance: Common rail injection systems can deliver fuel in a more precise and controlled manner, resulting in better engine performance and response.

- Quieter Operation: The high-pressure fuel delivery of common rail injection systems results in quieter engine operation.

- Increased Durability: Common rail injection systems are generally more reliable and durable than traditional fuel injection systems, thanks to their electronically controlled injectors and precise fuel delivery.

Disadvantages:

- Cost: Common rail injection systems can be more expensive to manufacture and install than traditional fuel injection systems.

- Maintenance: Common rail injection systems require more maintenance than traditional fuel injection systems, as the high-pressure fuel lines and injectors need to be regularly cleaned and serviced.

- Complexity: Common rail injection systems are more complex than traditional fuel injection systems, requiring sophisticated electronics and sensors to control the fuel delivery.

- Compatibility: Common rail injection systems may not be compatible with older diesel engines, requiring retrofitting or upgrading to the engine’s fuel system.

- Higher Fuel Quality Requirements: Common rail injection systems require higher quality fuel with fewer impurities to operate effectively, which can be more expensive and difficult to find in some regions.

Overall, while common rail injection technology offers many advantages over traditional fuel injection systems, it also has some drawbacks that need to be considered. The increased cost, complexity, and maintenance requirements may be a deterrent for some, while others may see the benefits of improved fuel efficiency, reduced emissions, and better engine performance as outweighing the drawbacks.