A cone-shaped diaphragm spring is a type of spring used in various applications such as automotive clutches, industrial clutches, and other mechanical systems where a compact and efficient spring is required. In this blog, we will discuss what a cone-shaped diaphragm spring is, how it works, and its advantages over other types of springs.

What is a cone-shaped diaphragm spring?

A cone-shaped diaphragm spring is a type of spring that has a conical shape, and it is made of a thin metal sheet. It is designed to work in compression, and it is used to apply a force to two surfaces that are in contact with each other. The shape of the cone-shaped diaphragm spring allows it to provide a large amount of force in a small space, making it ideal for use in applications where space is limited.

How does a cone-shaped diaphragm spring work?

A cone-shaped diaphragm spring works by applying a force to two surfaces that are in contact with each other. The spring is designed to work in compression, and when a force is applied to it, it compresses, which in turn applies a force to the surfaces in contact. The amount of force that the spring can provide is determined by its shape, the thickness of the metal sheet, and the amount of compression applied to it.

Advantages of cone-shaped diaphragm spring

- Compact design: The conical shape of the diaphragm spring allows it to be used in applications where space is limited. It is often used in automotive clutches, where a compact design is necessary.

- Efficient: Cone-shaped diaphragm springs are highly efficient because they can provide a large amount of force in a small space. They are also able to provide a constant force over a range of deflections.

- Durable: Cone-shaped diaphragm springs are made of high-quality materials, which makes them durable and long-lasting. They are able to withstand high temperatures and harsh environments.

- Cost-effective: The production of cone-shaped diaphragm springs is cost-effective because they are made of a thin metal sheet, which is easy to manufacture.

- Low noise: Cone-shaped diaphragm springs are designed to be quiet, which makes them ideal for use in applications where noise is a concern.

Conclusion

A cone-shaped diaphragm spring is a highly efficient and compact spring that is used in a variety of applications. Its conical shape allows it to provide a large amount of force in a small space, making it ideal for use in applications where space is limited. Cone-shaped diaphragm springs are also durable, cost-effective, and quiet, which makes them an excellent choice for many different applications.

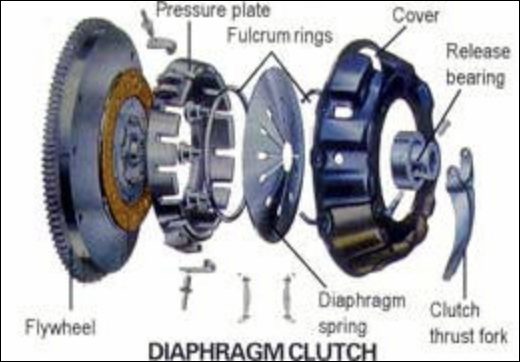

Cone-shaped diaphragm springs are often used in automotive clutches because they can provide a constant force over a range of deflections. In an automotive clutch, the cone-shaped diaphragm spring is used to apply pressure to the clutch disc, which in turn allows the engine to transfer power to the transmission.

One of the advantages of cone-shaped diaphragm springs over other types of springs, such as coil springs or leaf springs, is their ability to provide a constant force over a range of deflections. This means that the force applied by the spring remains the same, regardless of how much the spring is compressed. This is important in applications where consistent pressure is required, such as in automotive clutches.

Cone-shaped diaphragm springs are also used in industrial clutches, where they are used to engage and disengage the clutch. In an industrial clutch, the cone-shaped diaphragm spring is used to apply pressure to the clutch disc, which allows the machinery to transfer power to the driven components.

In addition to their use in clutches, cone-shaped diaphragm springs are also used in other mechanical systems, such as brakes and vibration dampers. They are ideal for use in applications where space is limited, as their compact design allows them to be used in tight spaces.

Overall, cone-shaped diaphragm springs are an efficient and effective type of spring that is used in a variety of applications. Their ability to provide a constant force over a range of deflections, along with their compact design, make them an ideal choice for many different mechanical systems.