The common rail system is an advanced fuel injection system used in diesel engines. It was developed in the late 1990s and has since become the industry standard in diesel engines. In this blog post, we will discuss what the common rail system is, how it works, and its benefits.

What is a Common Rail System?

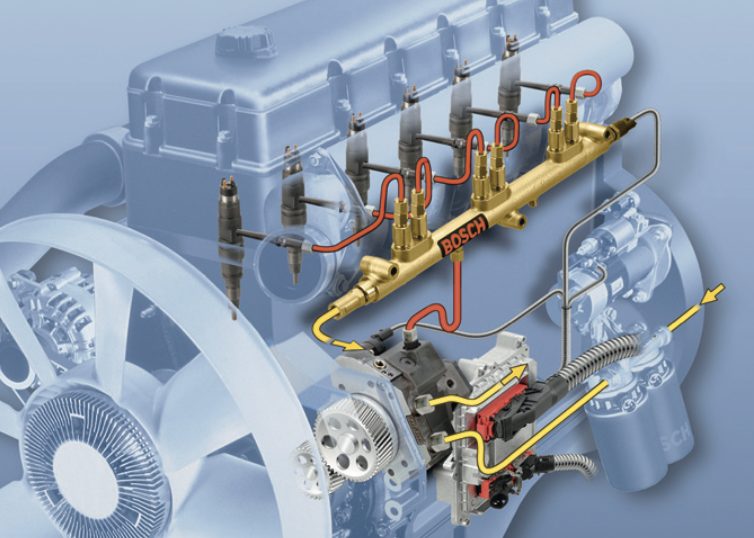

A common rail system is a type of fuel injection system that uses a high-pressure fuel rail to supply fuel to each individual fuel injector. The fuel is stored in the fuel tank and is pressurized by the fuel pump before entering the fuel rail. The fuel rail then distributes the fuel to each fuel injector, which sprays the fuel into the engine’s combustion chamber.

How does it work?

The common rail system is a high-pressure fuel injection system that uses an electronic control unit (ECU) to regulate the fuel pressure and timing. The ECU monitors various engine parameters, such as engine speed, load, and temperature, to determine the ideal fuel pressure and timing for each injection event.

The fuel is stored in the fuel tank and is pressurized by the fuel pump before entering the fuel rail. The fuel rail maintains a constant high pressure, typically between 1,500 and 3,000 psi, which allows for precise control of the fuel injection process.

When the ECU signals a fuel injection event, the fuel injector opens and sprays a precise amount of fuel into the engine’s combustion chamber. The high-pressure fuel allows for a more efficient and complete combustion, resulting in improved engine performance and reduced emissions.

Benefits of a Common Rail System

- Improved Fuel Efficiency: The common rail system delivers precise amounts of fuel at high pressure, resulting in a more efficient and complete combustion process. This leads to improved fuel efficiency and reduced emissions.

- Improved Performance: The high-pressure fuel injection allows for more precise control of the fuel delivery, resulting in improved engine performance and responsiveness.

- Reduced Emissions: The common rail system’s precise fuel injection process leads to reduced emissions of harmful pollutants, such as nitrogen oxides and particulate matter.

- Quieter Operation: The common rail system’s precise fuel injection process also results in quieter engine operation, as there is less fuel combustion noise.

- Reduced Maintenance: The common rail system’s high-pressure fuel injection system is less prone to clogging and other maintenance issues, resulting in reduced maintenance requirements and costs.

Conclusion

The common rail system is an advanced fuel injection system used in diesel engines that delivers precise amounts of fuel at high pressure. The system has several benefits, including improved fuel efficiency, improved performance, reduced emissions, quieter operation, and reduced maintenance requirements. As the industry standard in diesel engines, the common rail system is an important technology in the automotive industry, and its continued development and refinement will likely lead to even greater efficiency and performance gains in the future.

One of the key advantages of the common rail system is its ability to deliver multiple injections per combustion cycle. This is achieved by precisely controlling the fuel pressure and timing of each injection event. By doing so, the system can optimize the combustion process for different engine conditions, such as idle, low load, and high load. This results in improved fuel efficiency and reduced emissions.

Another benefit of the common rail system is its flexibility in fuel delivery. Unlike older fuel injection systems, which relied on mechanical pumps and injectors, the common rail system uses electronic control units to precisely regulate the fuel delivery. This allows for a wide range of injection pressures and fuel delivery rates, making the system compatible with a variety of engine designs and performance requirements.

In addition, the common rail system has the ability to detect and compensate for variations in fuel quality and temperature. This is achieved through the use of sensors that monitor the fuel pressure, temperature, and flow rate. The ECU can then adjust the fuel delivery parameters to compensate for any variations, ensuring consistent engine performance and emissions control.

Overall, the common rail system represents a significant advancement in diesel engine technology. Its precise fuel delivery and control capabilities allow for improved fuel efficiency, reduced emissions, and quieter operation. As diesel engines continue to play an important role in transportation and industrial applications, the common rail system is likely to remain a key technology in the industry.

Advantages:

- Improved Fuel Efficiency: The precise fuel injection and control capabilities of the common rail system result in improved fuel efficiency, leading to cost savings and reduced emissions.

- Increased Power and Performance: The high-pressure fuel injection allows for improved combustion and increased power and performance.

- Reduced Emissions: The precise control of the fuel injection process results in reduced emissions of harmful pollutants, such as nitrogen oxides and particulate matter.

- Quieter Operation: The common rail system’s precise fuel injection process results in quieter engine operation, as there is less fuel combustion noise.

- Flexibility: The electronic control unit allows for a wide range of injection pressures and fuel delivery rates, making the system compatible with a variety of engine designs and performance requirements.

Disadvantages:

- Higher Cost: The common rail system is more complex and expensive than traditional fuel injection systems, which can make it more costly to manufacture and repair.

- Increased Complexity: The electronic control unit and other components of the common rail system add complexity to the engine, which can increase the likelihood of failures and require specialized technicians to diagnose and repair.

- Sensitivity to Fuel Quality: The high-pressure fuel injection system of the common rail system is sensitive to variations in fuel quality, which can affect engine performance and require additional maintenance.

- Potential for Injector Clogging: The high-pressure fuel system of the common rail system can make the fuel injectors more susceptible to clogging, which can reduce performance and require maintenance.

- Limited Compatibility: The common rail system is primarily used in diesel engines, which limits its compatibility with other types of engines.

Overall, the advantages of the common rail system, such as improved fuel efficiency, increased power and performance, and reduced emissions, make it an important technology in the automotive and industrial sectors. However, its higher cost, increased complexity, and sensitivity to fuel quality and injector clogging can make it more challenging to manufacture and maintain.