Common rail injection combustion is a modern diesel fuel injection technology that has revolutionized the way diesel engines operate. Unlike older diesel engine technologies that relied on mechanical fuel injection systems, common rail injection combustion uses an electronic control unit (ECU) to precisely manage the delivery of fuel to the engine.

How it Works:

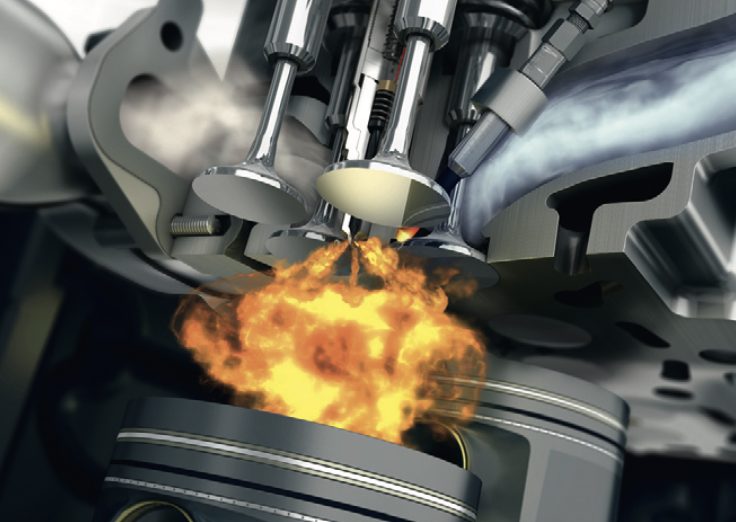

The basic principle behind common rail injection combustion is that fuel is delivered to a common rail (a high-pressure accumulator) which then supplies the fuel injectors with high-pressure fuel on demand. The fuel injectors then atomize the fuel and inject it directly into the engine’s combustion chamber, where it is ignited by the heat generated by compressed air. This process is called compression ignition and is what makes diesel engines so efficient.

Benefits:

One of the biggest advantages of common rail injection combustion is its ability to deliver fuel at very high pressures. This allows for more precise control over the fuel injection process, which in turn leads to better fuel efficiency, lower emissions, and improved performance. Common rail injection combustion also allows for multiple injections per combustion cycle, which can further improve efficiency and reduce emissions.

Another advantage of common rail injection combustion is its ability to operate at very high pressures without suffering from injector clogging or other issues commonly associated with older diesel engine technologies. This makes common rail injection combustion engines more reliable and durable than their predecessors.

Applications:

Common rail injection combustion is now used in a wide range of diesel engine applications, from small passenger cars to large commercial trucks and even marine engines. This technology has become increasingly popular in recent years due to its ability to meet increasingly strict emissions standards while still delivering the performance and efficiency that diesel engines are known for.

In addition to its use in diesel engines, common rail injection combustion is also being explored for use in other types of engines, including gasoline engines and even hybrid powertrains.

Conclusion:

Overall, common rail injection combustion is a powerful technology that has greatly improved the efficiency and performance of diesel engines. As emissions standards continue to become more stringent, it is likely that this technology will become even more important in the years to come. By allowing for more precise control over fuel injection, common rail injection combustion is helping to reduce emissions and improve the sustainability of diesel engines, making them a more attractive option for a wide range of applications.

Common rail injection combustion is a fuel injection technology that was developed in the late 1990s and early 2000s. It was first introduced by the automotive manufacturer, Fiat, in its Alfa Romeo 156 JTD in 1997. Since then, it has been widely adopted by other automakers and has become the standard fuel injection technology for modern diesel engines.

One of the key advantages of common rail injection combustion is its ability to precisely control the fuel delivery process. In traditional mechanical fuel injection systems, the fuel is delivered to the injectors at a fixed pressure, which can lead to inconsistencies in the fuel delivery process. With common rail injection combustion, the fuel is delivered to the common rail at a high pressure, typically between 1,500 and 3,000 bar, and then distributed to the individual injectors on demand. This allows for more precise control over the fuel delivery process, which can result in better fuel efficiency and reduced emissions.

Another advantage of common rail injection combustion is its ability to deliver multiple injections per combustion cycle. This is achieved by using advanced fuel injectors that can operate at very high speeds and pressures. By delivering multiple injections, the engine can achieve better fuel efficiency and reduced emissions, as well as improved performance.

Common rail injection combustion also allows for faster and more accurate adjustments to the fuel delivery process. The electronic control unit (ECU) can monitor various engine parameters, such as engine speed, load, and temperature, and adjust the fuel delivery process accordingly. This allows for optimal performance under a wide range of operating conditions.

Finally, common rail injection combustion has helped to reduce the noise and vibration commonly associated with older diesel engines. By delivering fuel at high pressures and using advanced injectors, the combustion process can be made smoother and quieter, leading to a more pleasant driving experience.

Overall, common rail injection combustion is a powerful technology that has greatly improved the efficiency, performance, and sustainability of diesel engines. As emissions standards continue to become more stringent, it is likely that this technology will become even more important in the years to come.

Advantages:

- Improved Fuel Efficiency: Common rail injection combustion enables the precise control of fuel delivery, which helps to maximize fuel efficiency. This technology allows for multiple injections per combustion cycle, which further enhances the fuel efficiency of diesel engines.

- Lower Emissions: Common rail injection combustion technology helps to reduce emissions of harmful pollutants such as nitrogen oxides (NOx) and particulate matter. By controlling the fuel delivery process more precisely, this technology enables engines to burn fuel more cleanly and efficiently, leading to lower emissions.

- Improved Performance: Common rail injection combustion can improve the performance of diesel engines by delivering fuel at high pressures, which leads to better combustion and more power output. This technology also enables faster and more accurate adjustments to the fuel delivery process, allowing engines to perform optimally under a wide range of operating conditions.

- Durability: Common rail injection combustion technology is more reliable and durable than older diesel engine technologies. By using electronic control units (ECUs) to manage fuel delivery, common rail injection combustion systems can avoid common problems such as clogging of fuel injectors, leading to longer engine lifespan.

Disadvantages:

- High Cost: Common rail injection combustion technology is more expensive than older diesel engine technologies. This is due to the need for high-pressure fuel pumps, advanced injectors, and electronic control units (ECUs), all of which add to the cost of production.

- Maintenance Costs: Although common rail injection combustion systems are more durable than older diesel engine technologies, they still require regular maintenance to keep them running efficiently. Maintenance costs can be higher than older diesel engines due to the complexity of the system.

- Complexity: Common rail injection combustion technology is more complex than older diesel engine technologies. This complexity can make it more difficult to diagnose and repair issues when they arise. Technicians require specialized training and equipment to work on common rail injection combustion systems, which can add to the cost of maintenance and repair.

- Fuel Quality: Common rail injection combustion systems are sensitive to the quality of fuel they use. Low-quality fuels can cause issues such as injector clogging, which can lead to decreased performance and increased maintenance costs.

In summary, common rail injection combustion has numerous advantages such as improved fuel efficiency, lower emissions, improved performance, and durability. However, it also has some disadvantages such as high cost, maintenance requirements, complexity, and sensitivity to fuel quality.