Diesel engines are popular in the automotive industry due to their high fuel efficiency and durability. One of the most important components of a diesel engine is the fuel injection system, which injects fuel into the engine’s combustion chamber. There are several types of diesel injection systems available, each with its own advantages and disadvantages. In this blog, we will discuss the most common types of diesel injection systems.

- Direct Injection Direct injection is the most common type of diesel injection system used in modern diesel engines. In a direct injection system, the fuel is injected directly into the combustion chamber, which allows for more efficient fuel combustion and better engine performance. Direct injection systems can be further classified into two types: common rail injection and unit injection.

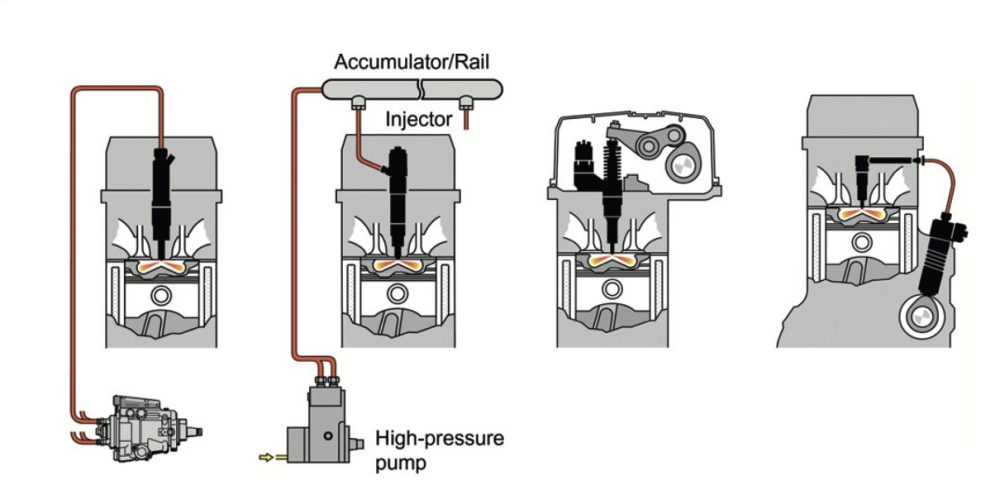

a) Common Rail Injection In common rail injection systems, fuel is supplied to a common rail or fuel accumulator at high pressure. The fuel pressure is then regulated by a pressure control valve, which ensures that the correct amount of fuel is delivered to the injectors. Common rail injection systems are known for their accuracy and ability to deliver precise amounts of fuel to the engine.

b) Unit Injection In unit injection systems, each cylinder has its own injector that is located inside the cylinder head. The fuel is delivered to the injector at high pressure, and the injector then sprays the fuel directly into the combustion chamber. Unit injection systems are known for their durability and ability to operate at high pressures.

- Indirect Injection Indirect injection systems are also known as pre-chamber or IDI (Indirect Injection) systems. In this type of system, the fuel is injected into a pre-chamber or pre-combustion chamber before entering the main combustion chamber. The fuel in the pre-chamber is then ignited, which creates a flame that spreads into the main combustion chamber. Indirect injection systems are known for their simplicity and reliability.

- Distributor Injection Distributor injection systems are no longer used in modern diesel engines but were popular in the past. In this type of system, fuel is delivered to a distributor or rotary pump, which then distributes the fuel to each cylinder’s injector. Distributor injection systems are less efficient than direct injection systems, and they are also prone to wear and tear.

In conclusion, the type of diesel injection system used in an engine depends on various factors such as engine design, fuel efficiency, and performance requirements. Direct injection systems are the most common and efficient, while indirect injection systems are known for their reliability and simplicity. Distributor injection systems, on the other hand, are outdated and no longer used in modern diesel engines.

- Direct Injection Direct injection systems are the most common type of diesel injection systems used in modern diesel engines. They offer several advantages over other injection systems, such as improved fuel efficiency and better engine performance. Direct injection systems can be further classified into two types: common rail injection and unit injection.

a) Common Rail Injection In a common rail injection system, fuel is supplied to a common rail or fuel accumulator at high pressure. The fuel pressure is then regulated by a pressure control valve, which ensures that the correct amount of fuel is delivered to the injectors. Common rail injection systems are known for their accuracy and ability to deliver precise amounts of fuel to the engine, which results in improved fuel efficiency and better engine performance.

b) Unit Injection In a unit injection system, each cylinder has its own injector that is located inside the cylinder head. The fuel is delivered to the injector at high pressure, and the injector then sprays the fuel directly into the combustion chamber. Unit injection systems are known for their durability and ability to operate at high pressures. They are commonly used in heavy-duty diesel engines, such as those used in trucks and construction equipment.

- Indirect Injection Indirect injection systems are also known as pre-chamber or IDI (Indirect Injection) systems. In this type of system, the fuel is injected into a pre-chamber or pre-combustion chamber before entering the main combustion chamber. The fuel in the pre-chamber is then ignited, which creates a flame that spreads into the main combustion chamber. Indirect injection systems are known for their simplicity and reliability. They are commonly used in smaller diesel engines, such as those found in cars and light-duty trucks.

- Distributor Injection Distributor injection systems are no longer used in modern diesel engines but were popular in the past. In this type of system, fuel is delivered to a distributor or rotary pump, which then distributes the fuel to each cylinder’s injector. Distributor injection systems are less efficient than direct injection systems, and they are also prone to wear and tear.

In summary, direct injection systems are the most common and efficient type of diesel injection system, while indirect injection systems are known for their simplicity and reliability. Unit injection systems are commonly used in heavy-duty diesel engines, while indirect injection systems are commonly used in smaller diesel engines. Distributor injection systems are outdated and no longer used in modern diesel engines.

- Direct Injection

Advantages:

- Improved fuel efficiency and better engine performance due to precise fuel delivery

- Reduced emissions due to improved combustion efficiency

- Lower noise levels compared to other injection systems

- Ability to operate at high pressures, making them suitable for heavy-duty applications

Disadvantages:

- Higher manufacturing and maintenance costs due to the complexity of the system

- Susceptibility to fuel contamination and injector clogging, which can affect performance and cause engine damage

- Higher initial cost compared to indirect injection systems

- Indirect Injection

Advantages:

- Simpler design and lower manufacturing and maintenance costs

- Reliability and durability due to fewer moving parts

- Ability to operate on a wider range of fuels, including lower-quality fuels

Disadvantages:

- Lower fuel efficiency and engine performance compared to direct injection systems

- Higher emissions due to incomplete combustion

- Noisier operation compared to direct injection systems

- Distributor Injection

Advantages:

- Simpler design and lower manufacturing and maintenance costs

- Reliability and durability due to fewer moving parts

Disadvantages:

- Lower fuel efficiency and engine performance compared to direct injection systems

- Higher emissions due to incomplete combustion

- Prone to wear and tear, resulting in higher maintenance costs

- No longer used in modern diesel engines, making replacement parts difficult to find

In summary, direct injection systems offer improved fuel efficiency and better engine performance, but they are more complex and expensive compared to indirect injection systems. Indirect injection systems are simpler and more reliable, but they offer lower fuel efficiency and engine performance. Distributor injection systems are outdated and no longer used in modern diesel engines, but they offer simplicity and durability. Ultimately, the choice of diesel injection system depends on the specific needs of the application and the desired trade-offs between performance, cost, and reliability.