Actuators are electromechanical devices that enable an EMS to make things happen in the world. In the realm of EFI, these include such devices as fuel injectors, boost controllers, and

idle air control valves. Most but not all actuators are directly controlled by the ECU. EMS actuators include the following:

• Fuel delivery: electronic fuel injectors, electric fuel pumps,

variable duty-cycle fuel pumps, fuel pressure regulators

(FPR), and dual-fuel switching systems

• Air delivery: throttle angle controls, IAC stepper

motors (idle speed control), boost controls, electronic

wastegate controls, supercharger boost bleeds, and

supercharger clutches

• Nitrous delivery: single- and multi-stage solenoids and

pulse-modulated solenoid

• Temperature control: radiator fans and engine

compartment fans

• Ignition and spark delivery: ignition amplifiers and

coil drivers

• Knock control: water- and alcohol-injection solenoids and

boost timing retard

• Cam phasing and valve-lift controls

• Variable intake: plenum volume, runner length and

secondary runner actuators (i.e., TVIS)

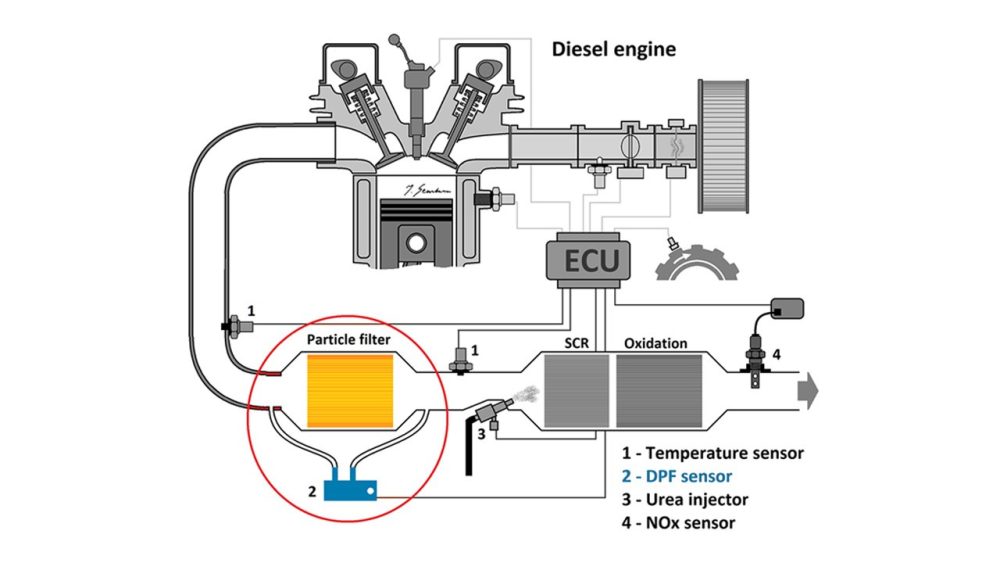

• Emissions controls (exhaust gas recirculation, air injection,

and so on)

• Transmission controllers and auxiliary onboard computers

• Information delivery: dash displays, diagnostics, and

telemmetry.

Imagine a nozzle on the end of a hose on a windy day: Squeeze the spring-loaded handle on the nozzle and water sprays out into the air. Release the handle and the spring closes the valve and the flow of water spray stops. The higher the pressure and the longer you squeeze, the more water comes out. If you imagine several nozzles on the same length of hose pointing in different directions, you are visualizing the situation in a port fuel-injected engine. Unlike most mechanical injection systems, which spray fuel constantly when the engine is running and regulate fuel delivery by varying the pressure, electronic fuel injectors use a timed-injection architecture, opening and closing with extreme rapidity at least once per combustion cycle to a resolution as

high as a 10,000th of a second in order to precisely spray gasoline into the charge air rushing through the intake manifold—or, in the case of direct-injection engines, directly into the combustion chambers. For a given size injection orifice and pressure drop through the injector, the amount of fuel delivered by electronic fuel injection is dependent on the length of time the injector is open.

The goal of EFI is always to deliver the charge mixture in a precisely targeted air/fuel ratio optimized to generate maximum cylinder pressure per injected fuel mass in order to efficiently push against the piston and cause the engine to get work done, ideally with the highest possible efficiency and the least possible air pollution. Injected fuel enters the charge air in pulses, but by the time fuel and air are in the cylinder and compressed, the fuel must be mixed with air as evenly as possible and fully vaporized, with at least some of the mixing and vaporization occurring inside the hot cylinders. An injection pressure of 30 psi above intake manifold pressure will shear fuel into a fine mist of fuel droplets of very small size with a lot of surface area that evaporate well and burn quickly. The larger the pressure drop through the injectors, the better the atomization.

Modern gasoline directinjection engines inject fuel with a rail pressure as high as 2,900 psi, and some modern diesel engines inject fuel at pressures as high as 25,000 psi. To inject fuel into the air in precisely timed pulses, electronic injector nozzles contain tiny electrically controlled valves actuated by electromagnetic or Piezoelectric circuitry that is powerful enough to overcome the force of a spring and fuel rail pressure to push the injection valve open in less than a millisecond. As the valve begins to open, pressure in the supply line causes fuel to begin spraying through a tiny metering orifice to mist out into the charge air in a precise pattern in the intake manifold or combustion chamber. The instant an injector is deenergized, the pressure of fuel and a spring immediately begin to force the injector closed, which is even quicker than opening time but requiring a tiny, but finite amount of time. Port fuel injectors are normally aimed directly at the hot intake valve to enhance vaporization, and direct injectors are aimed toward a recess in the piston crown that forms a partial pre-chamber around the spark plug when the piston is at top dead center to form a stratified-charge for lean-burn operations when it is advantageous to have a locally richer air/fuel mixture in the immediate vicinity of the spark plug to kindle combustion.

Robert Bosch GmbH, based in Europe, long ago licensed the rights from Bendix to build the “Electrojector” pulsed EFI system invented in the United States in the 1950s. Bosch has

built more than 150 million electronic injectors and currently dominates the market. Several other companies, including Lucas, Rochester, and Siemens, design and manufacture large numbers of electronic injectors.