An alternator is an electrical generator that is used to convert mechanical energy into electrical energy. It is an important component of modern cars, trucks, and other vehicles, as well as a wide range of industrial and residential applications. In this blog post, we will take a closer look at what an alternator is, how it works, and its various applications.

What is an Alternator?

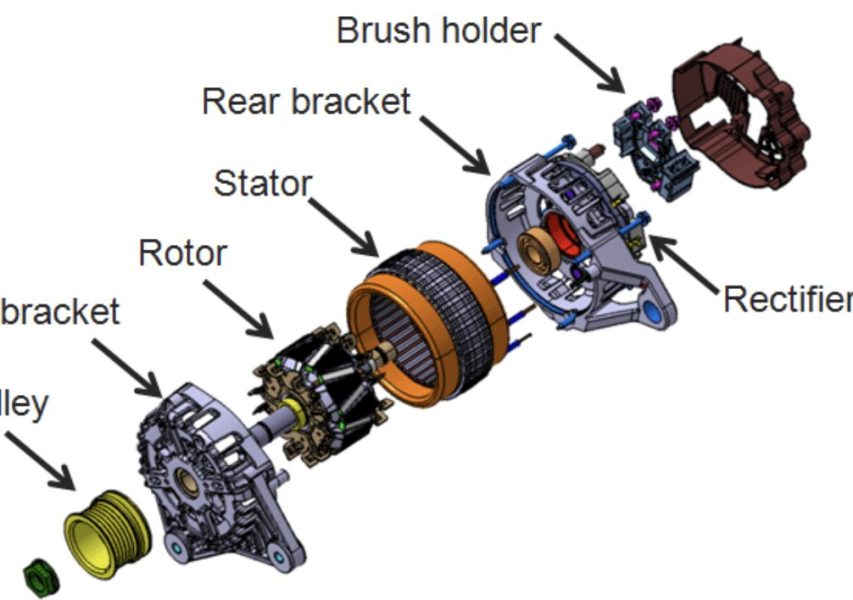

An alternator is a type of generator that produces electrical energy by converting mechanical energy. It typically consists of a rotor (rotating part) and a stator (stationary part) that work together to produce an alternating current (AC) output. The rotor is connected to the engine’s crankshaft, and when the engine is running, it spins the rotor. The stator, which surrounds the rotor, contains a series of copper wire coils that generate an electromagnetic field. As the rotor spins, it creates a changing magnetic field that induces an electrical current in the stator windings.

How Does an Alternator Work?

The alternator works by using the principle of electromagnetic induction. As the rotor spins, it generates a magnetic field, which cuts across the stator windings. This causes an electrical current to flow through the windings, which in turn generates an electromagnetic field. The strength and direction of this field change as the rotor spins, causing the current to alternate back and forth. The AC current produced by the alternator is then converted into a DC current by a rectifier, which is used to power the electrical systems of the vehicle or device.

What are the Applications of an Alternator?

Alternators are used in a wide range of applications, including:

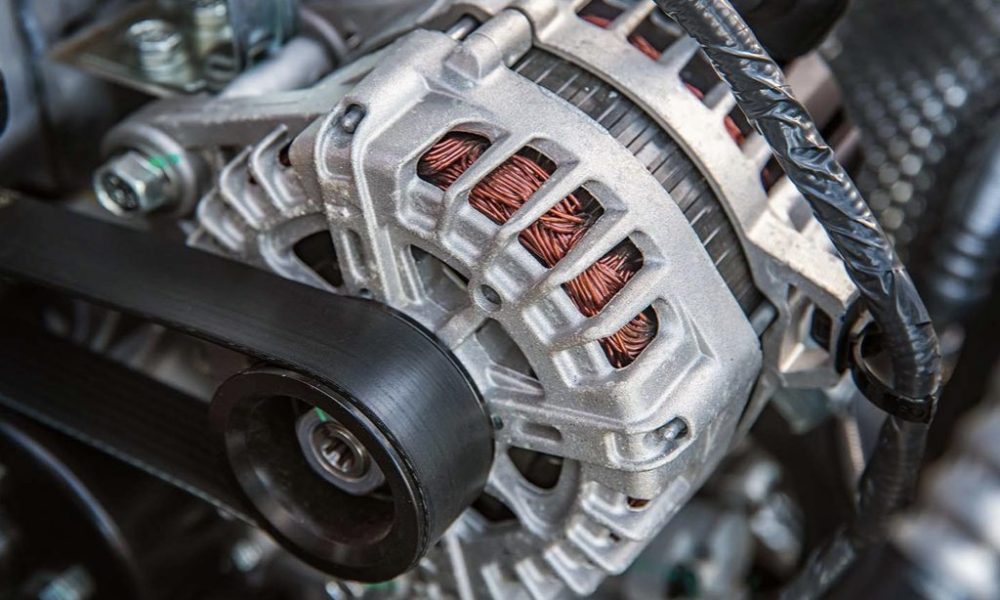

- Automotive: Alternators are commonly used in cars, trucks, and other vehicles to power the electrical systems, such as the headlights, radio, and air conditioning.

- Industrial: Alternators are also used in industrial applications, such as in power plants, to generate electricity.

- Residential: Alternators can be used in homes as backup generators to provide power during power outages.

- Marine: Alternators are used in boats and ships to generate electricity for the vessel’s electrical systems.

- Aviation: Alternators are used in aircraft to power the onboard electrical systems, such as the lighting, communication, and navigation systems.

Conclusion

In summary, an alternator is a type of electrical generator that converts mechanical energy into electrical energy. It works by using the principle of electromagnetic induction, and is used in a wide range of applications, from automotive to aviation. Alternators are an essential component of many electrical systems, and their reliability and efficiency make them a critical component in many industries.

One important aspect to note is that alternators are typically more efficient than traditional generators. Traditional generators use a commutator and brushes to transfer the electrical current from the rotating armature to the stationary output, which can result in significant energy loss and wear on the brushes. Alternators, on the other hand, use slip rings and brushes to transfer the electrical current, which results in less energy loss and longer-lasting components.

Another key feature of alternators is that they can produce a relatively high amount of electrical power even at low engine speeds. This is because the strength of the electromagnetic field in the stator windings is directly proportional to the speed of the rotor. Therefore, even when the engine is idling or running at low speeds, the alternator can still produce a significant amount of electrical power.

In terms of maintenance, alternators typically require very little attention over their lifespan. They are designed to be reliable and long-lasting, and usually only require periodic checks of the drive belt tension and electrical connections.

Finally, it’s worth noting that alternators can vary in size and output capacity depending on their intended application. For example, an alternator used in a small passenger car may have an output of around 60-100 amps, while an alternator used in a large commercial truck may have an output of 200-300 amps or more. Similarly, alternators used in industrial or power plant applications can have much higher output capacities to meet the demands of large electrical loads.

I hope this additional information helps to further clarify what an alternator is and how it works. Let me know if you have any other questions!

Advantages:

- High efficiency: Alternators are typically more efficient than traditional generators, which can lead to lower fuel consumption and reduced emissions.

- High output capacity: Alternators can produce a high amount of electrical power even at low engine speeds, making them ideal for a wide range of applications.

- Reliable: Alternators are designed to be reliable and long-lasting, and typically require very little maintenance over their lifespan.

- Versatile: Alternators can be used in a wide range of applications, from automotive to industrial and residential.

Disadvantages:

- Initial cost: Alternators can be more expensive than traditional generators, which may be a barrier for some applications.

- Complexity: Alternators are more complex than traditional generators, which can make them more difficult to repair or service.

- Weight: Alternators can be relatively heavy, which may be a concern for applications where weight is a critical factor, such as in aircraft.

- Electromagnetic interference: Alternators can produce electromagnetic interference (EMI) that can interfere with other electrical systems, which may require additional shielding or filtering.

Overall, the advantages of using an alternator typically outweigh the disadvantages, especially for applications where high output capacity, reliability, and efficiency are critical factors. However, it’s important to carefully consider the specific needs and requirements of each application before choosing between an alternator and other types of generators.